Preparation technology of hydrophilic MQ silicone resin

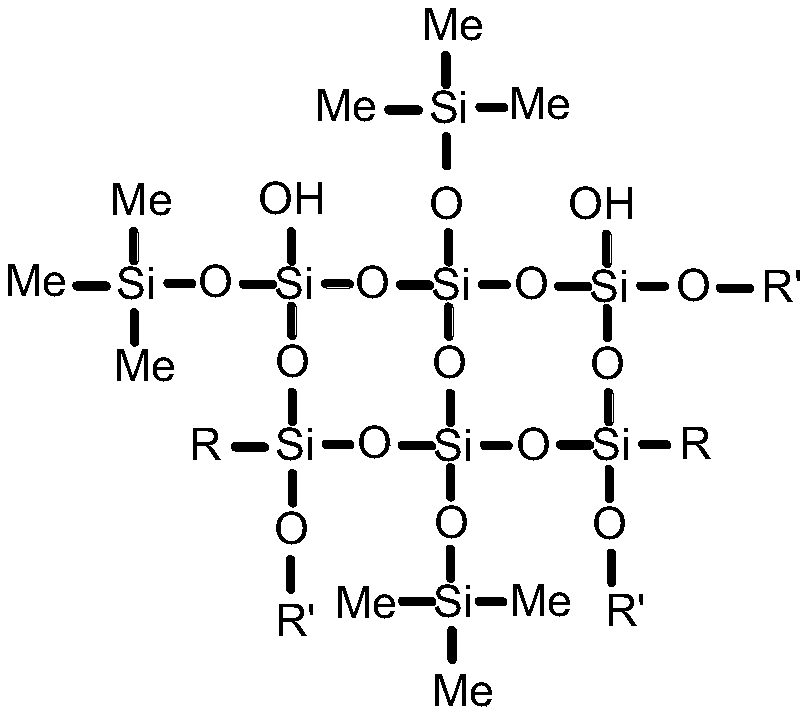

A technology of MQ silicone resin and preparation process, applied in the field of organic synthesis, can solve the problems of wide molar mass distribution, easy generation of gel, difficult control of structure and M/Q value, etc., and achieves the effect of high refractive index and broadening the application field.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] S1: To prepare modified alkoxysilane, add 0.55mol of unsaturated polyether and chloroplatinic acid catalyst into a flask, mix well, and heat up to 90°C for reaction. Slowly add 0.5 mol of trimethoxysilane into the flask dropwise, then keep the temperature for 2 hours, and remove the low boilers under reduced pressure to obtain modified alkoxysilane, that is, polyether modified trimethoxysilane.

[0029] In this embodiment, the unsaturated polyether structural formula is C 3 h 5 O-(C 2 h 4O ) m -(C 3 h 6 O) n -CH 3 , where m=0, n=2. The preparation method of the chloroplatinic acid catalyst is as follows: 1 weight part of chloroplatinic acid is dissolved in 10 weight parts of isopropanol to obtain the chloroplatinic acid catalyst. The dosage of chloroplatinic acid catalyst in this embodiment is 5 ppm of the total molar amount of trimethoxysilane and unsaturated polyether.

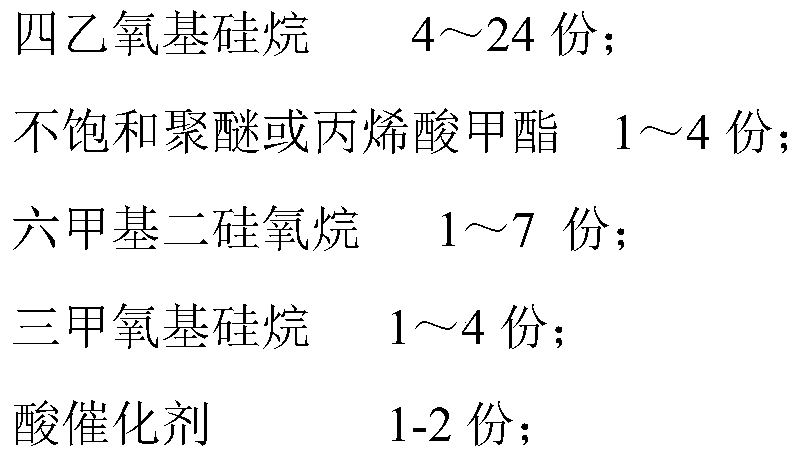

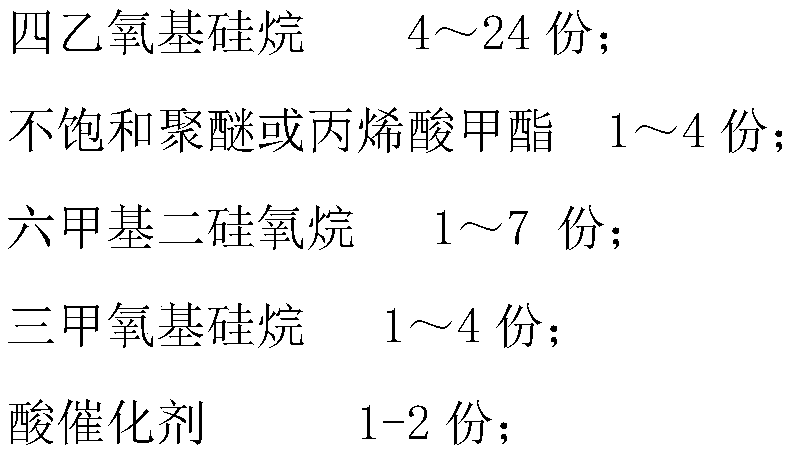

[0030] S2: Add the modified alkoxysilane obtained in step S1, 200 mL of isopropanol, 2.0...

Embodiment 2

[0033] S1: To prepare modified alkoxysilane, add 4 mol of unsaturated polyether and chloroplatinic acid catalyst into a flask, mix well, and heat up to 100°C for reaction. Slowly add 1 mol of trimethoxysilane into the flask dropwise, then keep the temperature for 1 hour, and remove the low boilers under reduced pressure to obtain modified alkoxysilane, that is, polyether modified trimethoxysilane.

[0034] In this embodiment, the unsaturated polyether structural formula is C 3 h 5 O-(C 2 h 4O ) m -(C 3 h 6 O) n -CH 3 , where m=8, n=5. The preparation method of the chloroplatinic acid catalyst is as follows: 1 weight part of chloroplatinic acid is dissolved in 30 weight parts of ethanol to obtain the chloroplatinic acid catalyst. The dosage of chloroplatinic acid catalyst in this embodiment is 20 ppm of the total molar amount of trimethoxysilane and unsaturated polyether.

[0035] S2: Add the modified alkoxysilane obtained in step S1, 200 mL of ethanol, 4 mol of tetra...

Embodiment 3

[0038] S1: To prepare modified alkoxysilane, add 2 mol of unsaturated polyether and chloroplatinic acid catalyst into a flask, mix well, and heat up to 60°C for reaction. Then slowly drop 2 mol of trimethoxysilane into the flask, and then keep the temperature for 3 hours, and remove the low boilers under reduced pressure to obtain modified alkoxysilane, that is, polyether modified trimethoxysilane.

[0039] In this embodiment, the unsaturated polyether structural formula is C 3 h 5 O-(C 2 h 4O ) m -(C 3 h 6 O) n -CH 3, where m=20, n=0. The preparation method of the chloroplatinic acid catalyst is as follows: 1 weight part of chloroplatinic acid is dissolved in 50 weight parts of tetramethyltetravinyl cyclotetrasiloxane to obtain the chloroplatinic acid catalyst. The dosage of the chloroplatinic acid catalyst in this embodiment is 50 ppm of the total molar amount of trimethoxysilane and unsaturated polyether.

[0040] S2: Add 400 mL of the modified alkoxysilane obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com