Construction method of anti-skid technology for tile roof

A technology of tile roofing and craftsmanship, which is applied to roof cladding, building roofs, etc., can solve the problems of insufficient strength of the lying mortar and unfixed tiles, etc., achieve the effect of simple construction technology, not easy to change, and solve the hidden danger of water leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] exist Figure 1~4 Among them, the tile roof anti-skid process construction method of the present invention comprises the following steps:

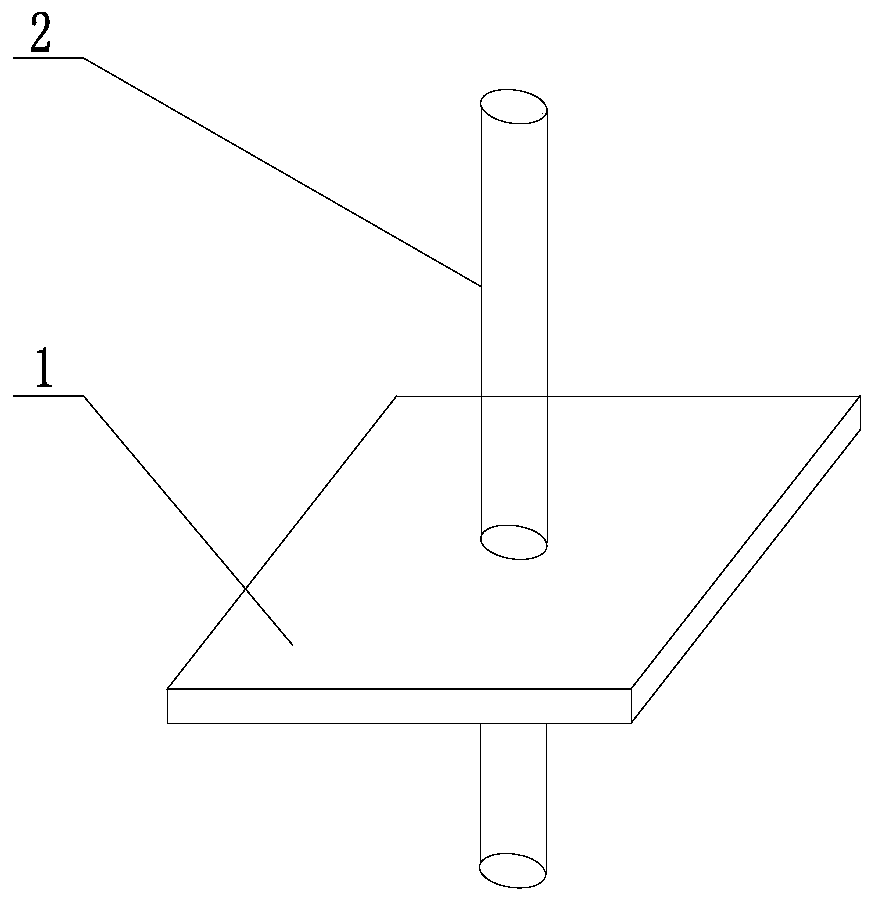

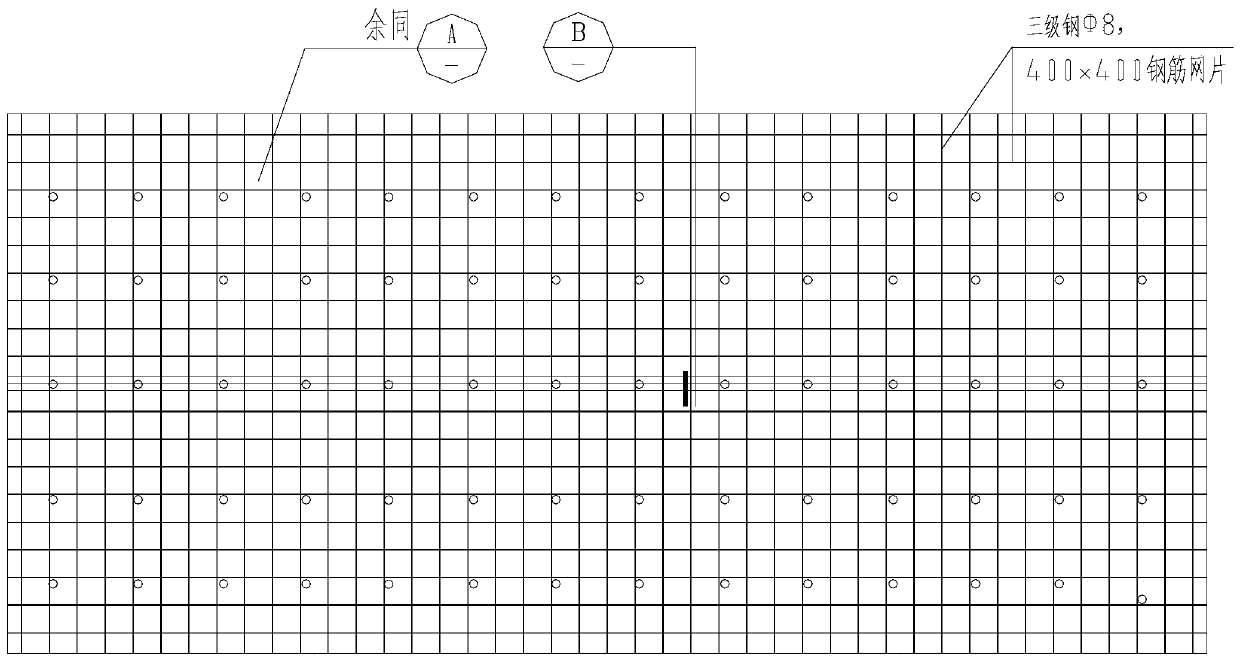

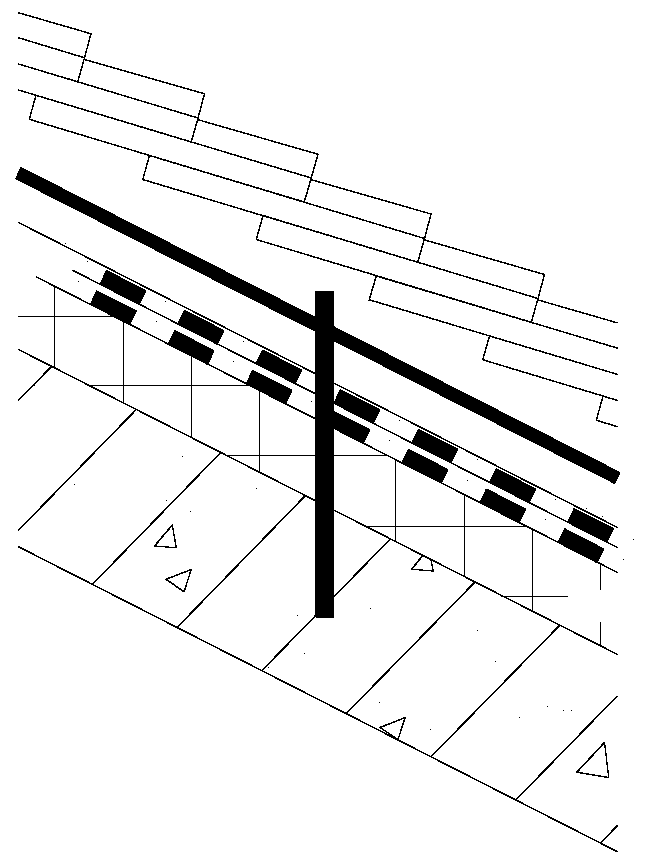

[0044] S1. Construction of anti-skid water-stop reinforcement: including the production of anti-skid water-stop reinforcement and pre-embedding of anti-skid water-stop reinforcement; the production of anti-skid water-stop reinforcement includes a piece of anti-skid water-stop reinforcement with a thickness of 4mm and a side length of 50mm Steel plate 1 × 50mm and two tertiary steel bars 2 with a diameter of 14mm are vertically welded. Among them, the length of the lower steel bar is 50mm, and the length of the upper steel bar is 170mm. The upper steel bar is embedded in concrete 10mm + insulation layer 80mm + waterproof layer 50mm + exposed waterproof protective layer 40mm, the pre-embedded anti-slip and water-stop steel bars must be treated with anti-rust; the pre-embedded anti-slip water-stop steel bars include the sloping roof re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com