Oxygen belt and acetylene belt wiring device for installing power station boiler,

A wiring device and power station boiler technology, which is applied in the direction of electrical components, gas/liquid distribution and storage, pipeline laying and maintenance, etc., can solve the problems of labor-intensive, occupying crane shifts, time-consuming and labor-intensive problems, and reduce the impact of the belt , prolong service life, increase the effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

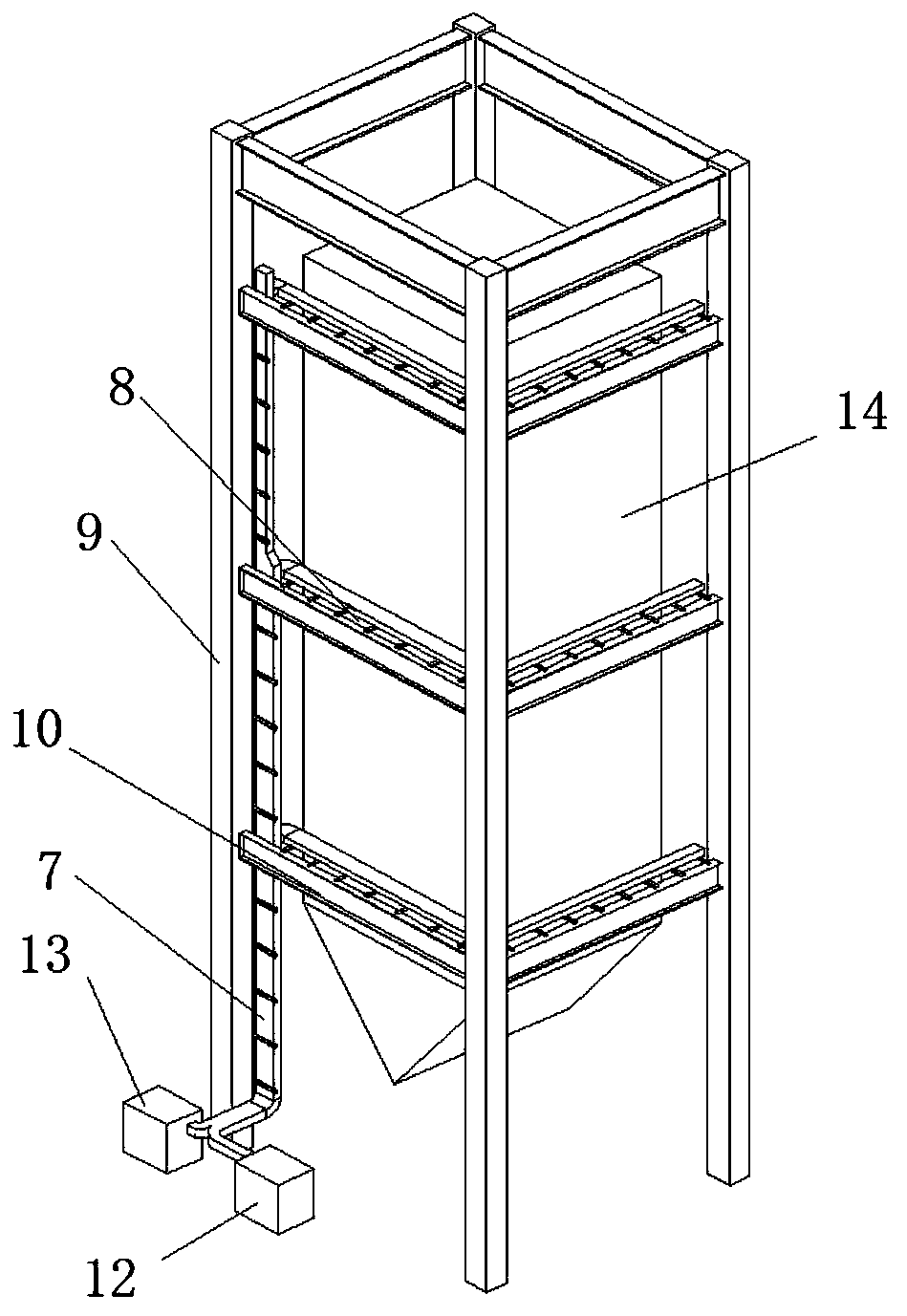

[0051] An oxygen belt and acetylene belt wiring device for power plant boiler installation is formed by assembling several main line parts, several branch line parts and several three-way parts. Main line components, branch line components and tee components are all welded with 3mm thick steel plates, and the outer surface is sandblasted to remove rust and painted with antirust paint.

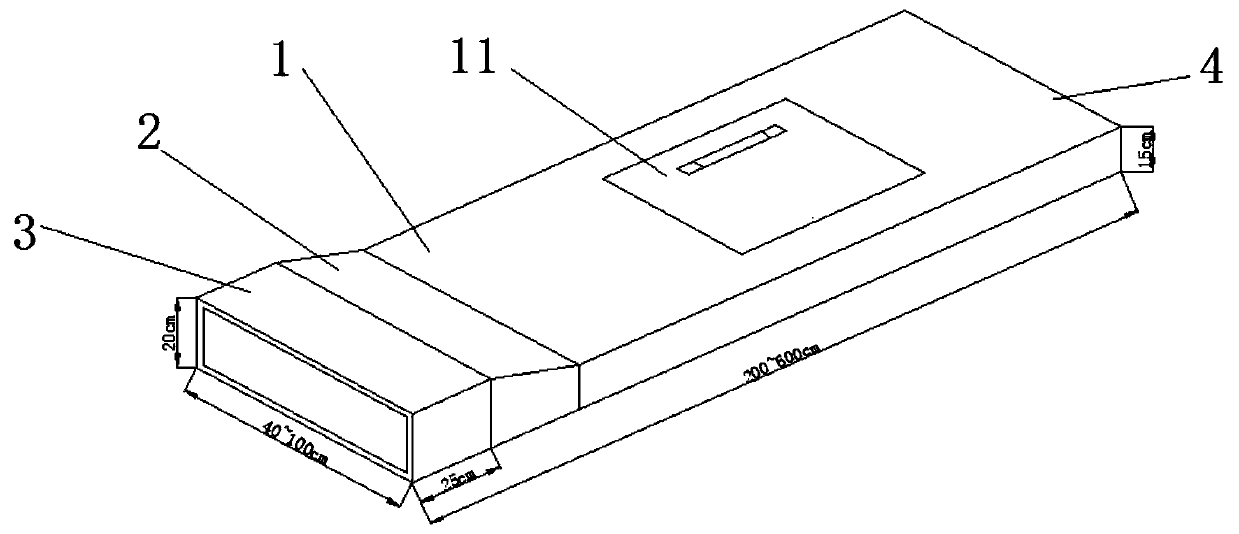

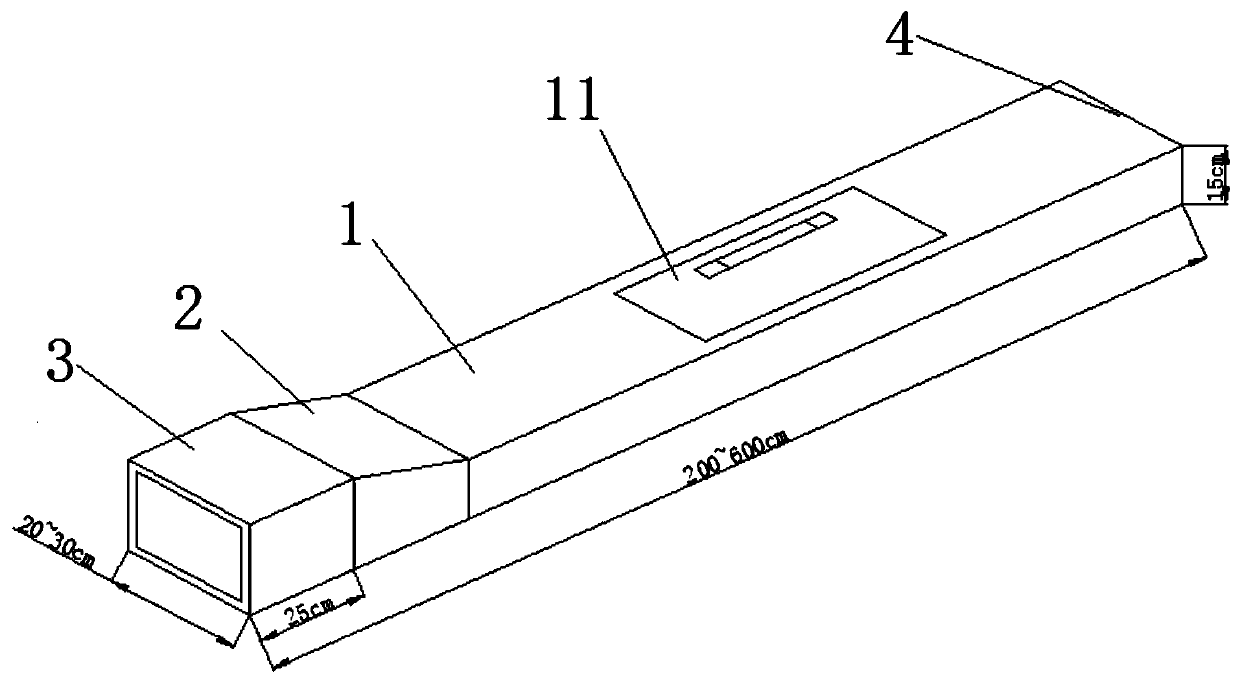

[0052] The structure of the main line part and the branch line part is the same. The main structure 1 of the main line part and the tee part is a square cylindrical structure. One end of the main structure 1 is connected to the interface 3 through the flared structure 2. The aspect ratio of the radial section of the main line part is equal to the aspect ratio of the radial section of the main structure 1, the radial cross-sectional area of the interface 3 is larger than the radial cross-sectional area of the main structure 1, and the other end of the main structure 1 of the main line part is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com