Water level sensor

A water level sensor and an integrated technology, applied in the field of sensors, can solve the problems of unreasonable assembly methods of sensors, affecting assembly efficiency and use effect, etc., to achieve improved assembly efficiency and measurement accuracy, reasonable air intake structure design, and reduced assembly process difficulty Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

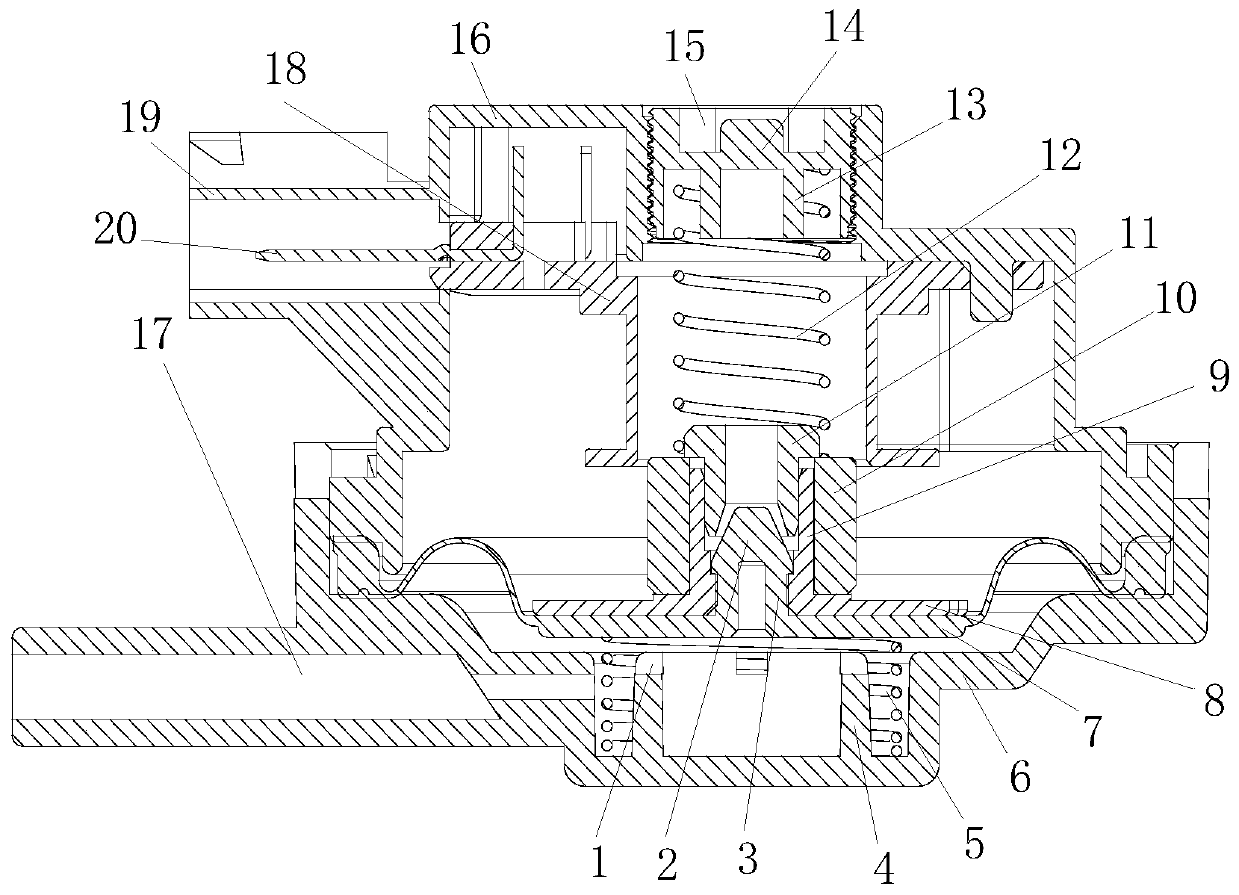

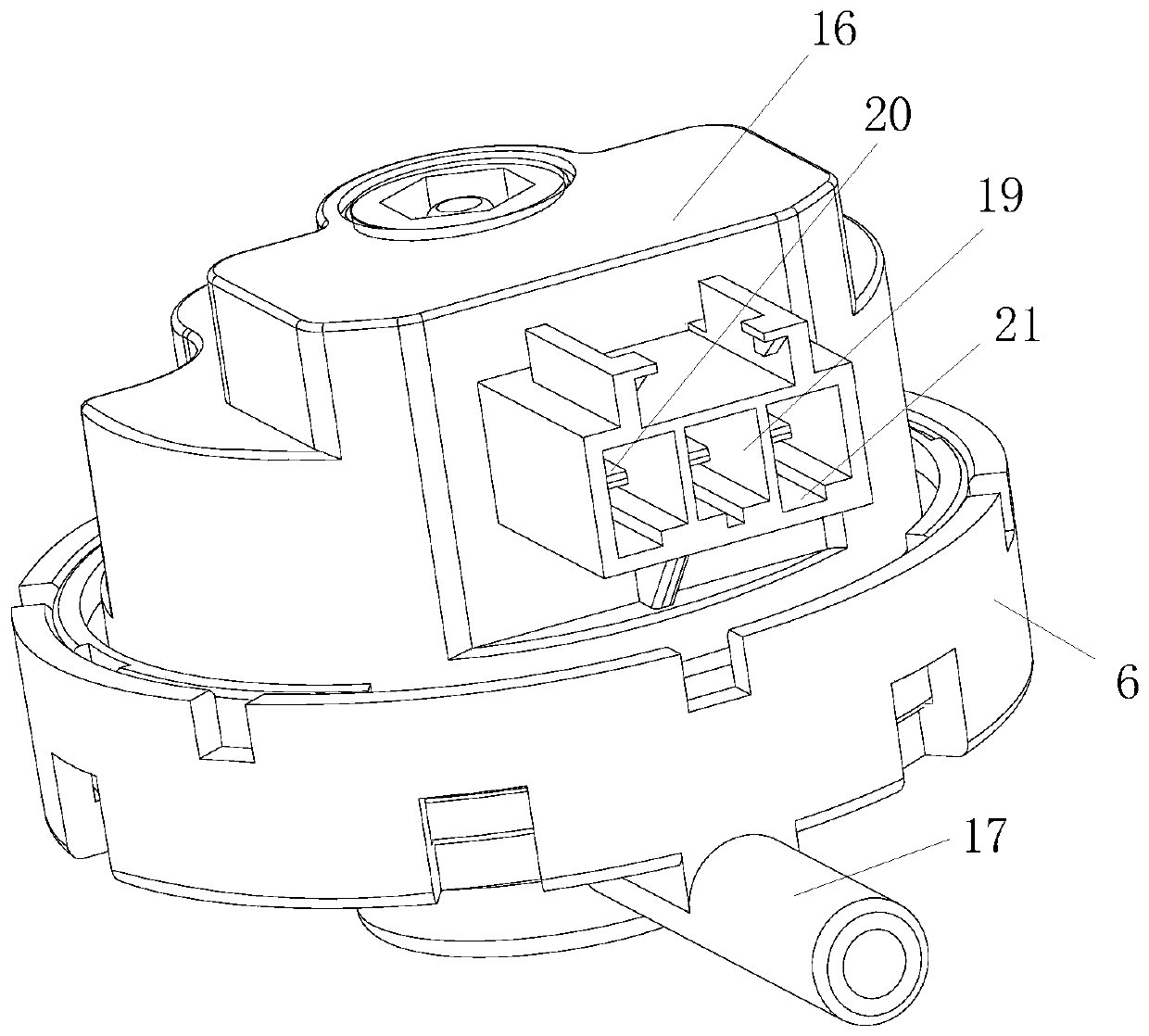

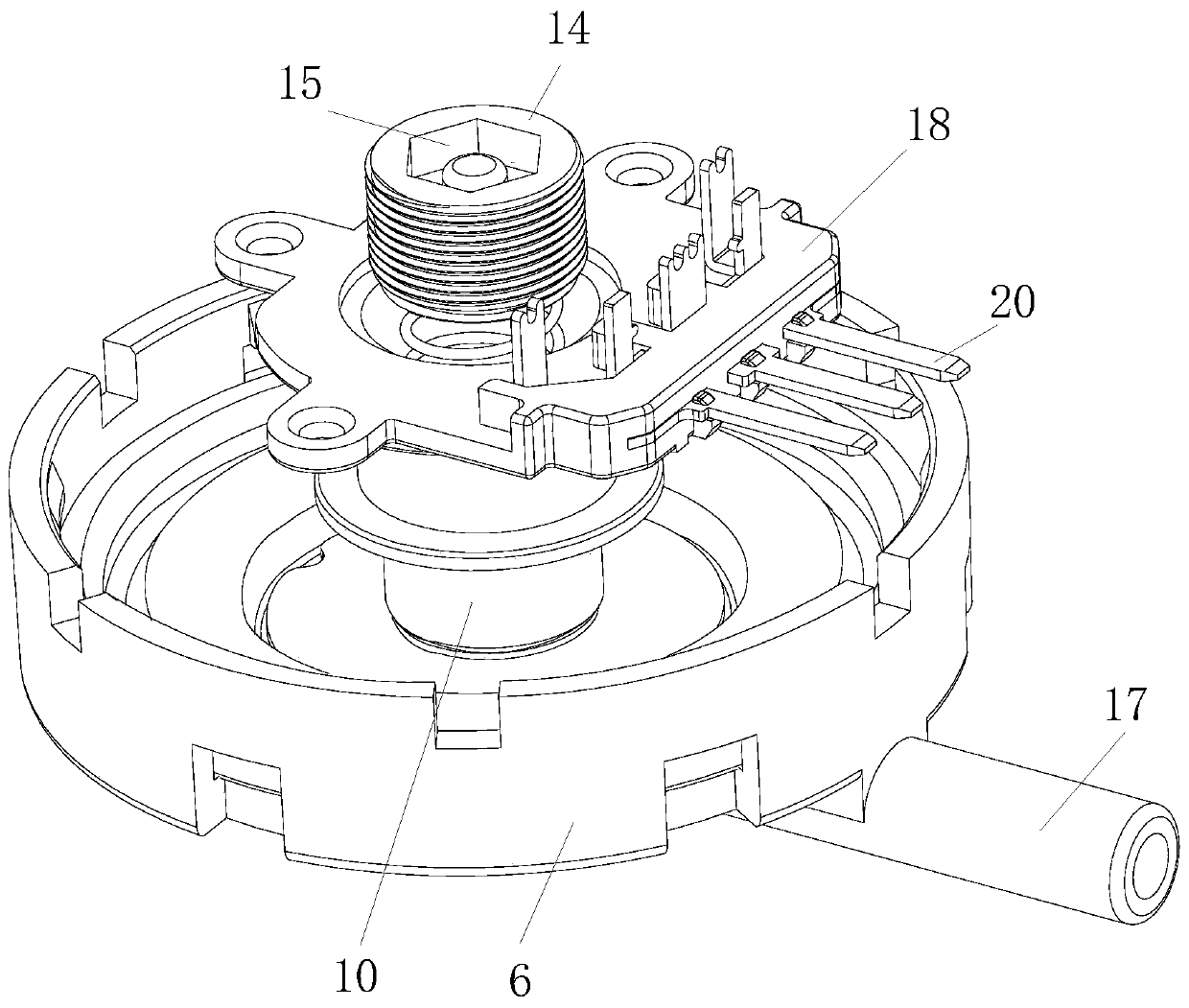

[0023] refer to Figure 1-4 , a water level sensor, comprising a lower casing 6 and an upper casing 16 connected together, one side of the lower casing 6 is provided with an air inlet passage 17, and in a sealed chamber formed between the lower casing 6 and the upper casing 16 There are detection components, the detection components include a silicone diaphragm 7, the silicone diaphragm 7 is fixed between the lower casing 6 and the upper casing 16, a cylinder 4 is arranged in the middle of the lower casing 6, and a coaxial sleeve is arranged on the cylinder 4. The first spring 5, the bottom plane of the silicone diaphragm 7 coincides with the top plane of the first spring 5, the silicone diaphragm 7 is supported on the upper part of the first spring 5, the cylinder 4 and the lower casing 6 are integrally formed, reducing assembly steps, and at the same time The bottom of the diaphragm 7 is provided with a first spring 5 to prevent the silicone diaphragm 7 from being sealed tog...

Embodiment 2

[0028] refer to Figure 1-4 , a water level sensor, comprising a lower casing 6 and an upper casing 16 connected together, one side of the lower casing 6 is provided with an air inlet passage 17, and in a sealed chamber formed between the lower casing 6 and the upper casing 16 There is a detection part, the detection part includes a silicone diaphragm 7, and the silica gel diaphragm 7 is fixed between the lower casing 6 and the upper casing 16, and the sealed chamber is divided into an upper chamber, a lower chamber, and a lower chamber by the silica gel diaphragm 7. The chamber is communicated with the air inlet channel 17, the upper part of the silicone diaphragm 7 is provided with a magnetic core 10, and the upper part of the middle part of the silica gel diaphragm 7 is provided with an integrally formed buckle assembly, which includes a hollow cylindrical section 3, a tapered chuck 2, a cone The outer diameter of the bottom end of the clamp head 2 is greater than the outer d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com