P-type metal oxide gas sensor and its preparation and use method

A gas sensor and oxide technology, applied in the direction of material resistance, can solve the problems of measuring gas range and performance limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The concrete steps of preparation are:

[0049] Step 1, first according to the weight ratio of 0.14wt% bacterial cellulose hydrogel and 1mmol / L metal salt solution is 20:22, immerse the bacterial cellulose hydrogel in the metal salt solution and let it stand for 12h, take out Finally, it is washed with deionized water; wherein, the bacterial cellulose in the bacterial cellulose hydrogel is cellulose of the genus Acetobacter, and the metal salt solution is nickel acetate solution in the acetate metal salt solution. Then it was freeze-dried at -50° C. for 2 days to obtain a cellulose xerogel with metal ions adsorbed thereon.

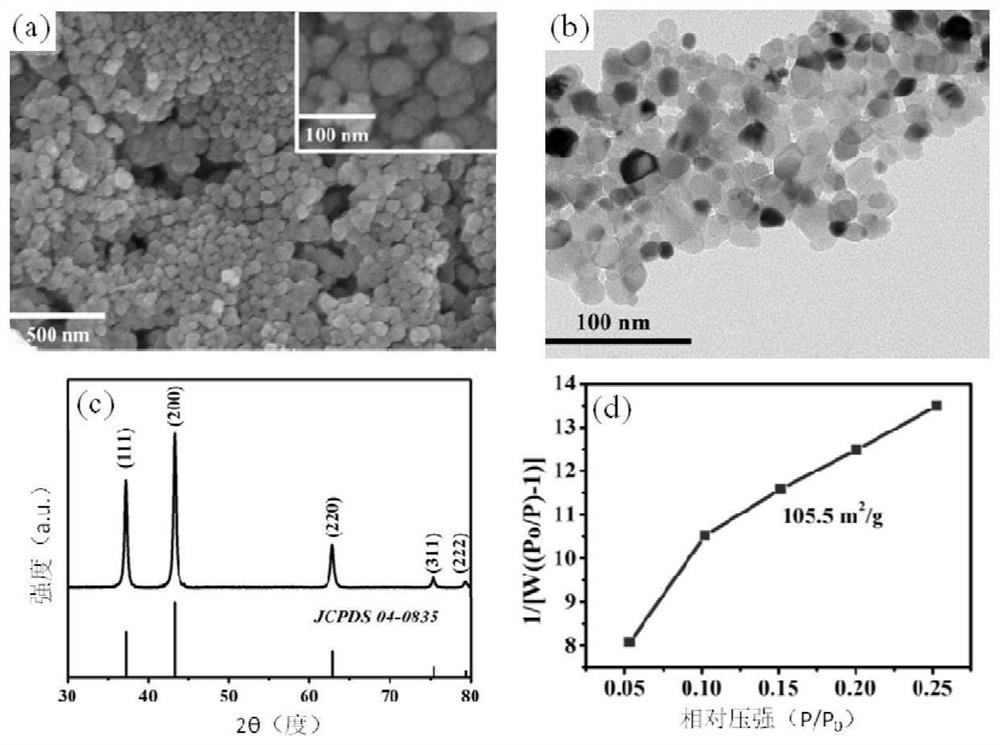

[0050] In step 2, the cellulose xerogel on which the metal ions are adsorbed is first calcined at 400° C. for 5 hours to obtain flocculent metal oxide particles. Then grind the mixture of the flocculent metal oxide particles and the volatile reagent; wherein the volatile reagent is water to obtain the metal oxide nano particle slurry.

[0051] In ...

Embodiment 2

[0053] The concrete steps of preparation are:

[0054] Step 1, according to the weight ratio of 0.145wt% bacterial cellulose hydrogel and 0.75mmol / L metal salt solution is 65:21, immerse the bacterial cellulose hydrogel in the metal salt solution and let it stand for 21h, After being taken out, it is rinsed with deionized water; wherein, the bacterial cellulose in the bacterial cellulose hydrogel is cellulose of the genus Acetobacter, and the metal salt solution is nickel acetate solution in the acetate metal salt solution. Then it was freeze-dried at -53°C for 1.8 days to obtain a cellulose xerogel with metal ions adsorbed thereon.

[0055] In step 2, the cellulose xerogel on which the metal ions are adsorbed is first calcined at 500° C. for 4 hours to obtain flocculent metal oxide particles. Then grind the mixture of the flocculent metal oxide particles and the volatile reagent; wherein the volatile reagent is water to obtain the metal oxide nano particle slurry.

[0056] ...

Embodiment 3

[0058] The concrete steps of preparation are:

[0059] Step 1, according to the weight ratio of 0.15wt% bacterial cellulose hydrogel and 0.5mmol / L metal salt solution of 110:20, immerse the bacterial cellulose hydrogel in the metal salt solution and let it stand for 30h, After being taken out, it is rinsed with deionized water; wherein, the bacterial cellulose in the bacterial cellulose hydrogel is cellulose of the genus Acetobacter, and the metal salt solution is nickel acetate solution in the acetate metal salt solution. Then it was freeze-dried at -55°C for 1.5 days to obtain a cellulose xerogel with metal ions adsorbed thereon.

[0060] In step 2, the cellulose xerogel on which the metal ions are adsorbed is first calcined at 600° C. for 3 hours to obtain flocculent metal oxide particles. Then grind the mixture of the flocculent metal oxide particles and the volatile reagent; wherein the volatile reagent is water to obtain the metal oxide nano particle slurry.

[0061] I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com