Filter, test system and filter preparation method

A test system and filter technology, which is applied in the field of photoelectric detection, can solve the problems of inability to filter high-frequency signals, and achieve the effects of saving filter space, low cost, and low production difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

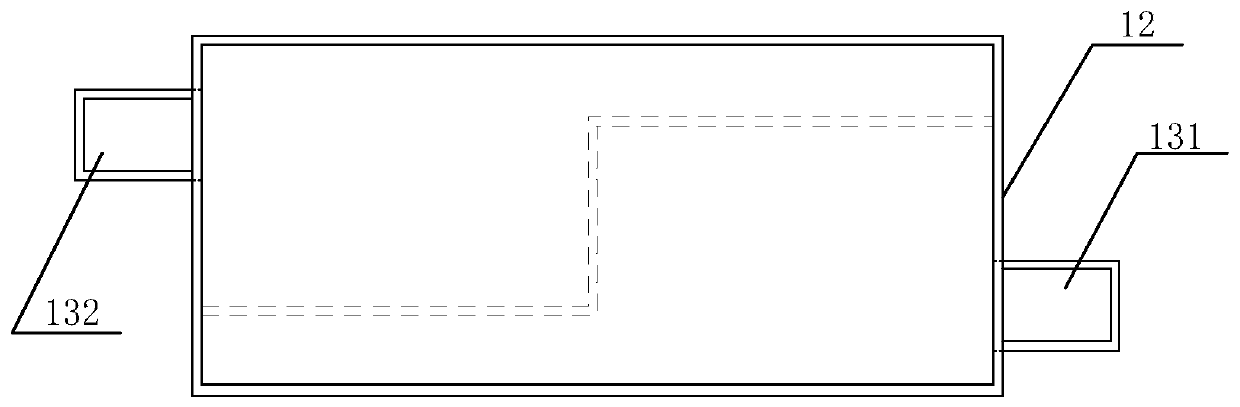

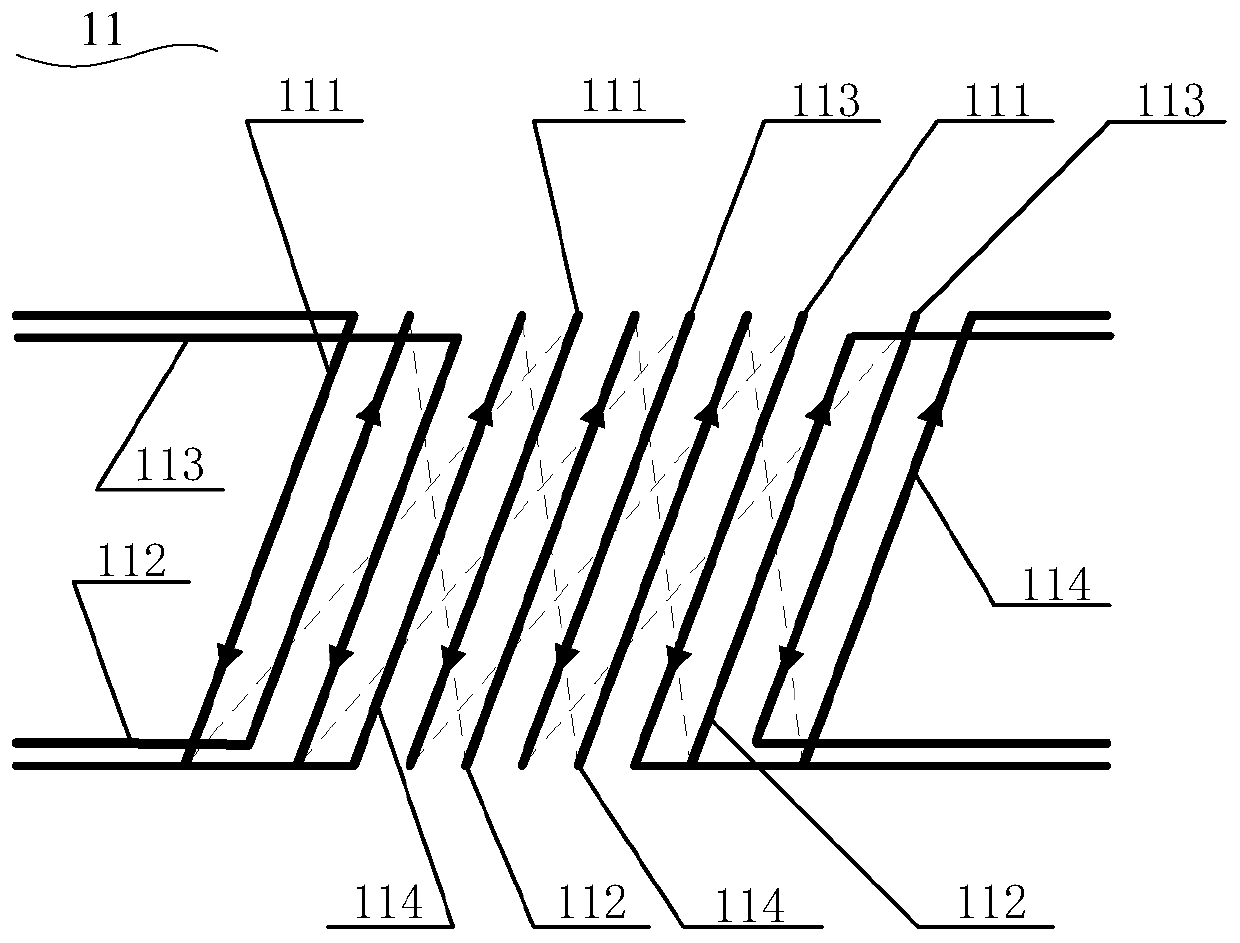

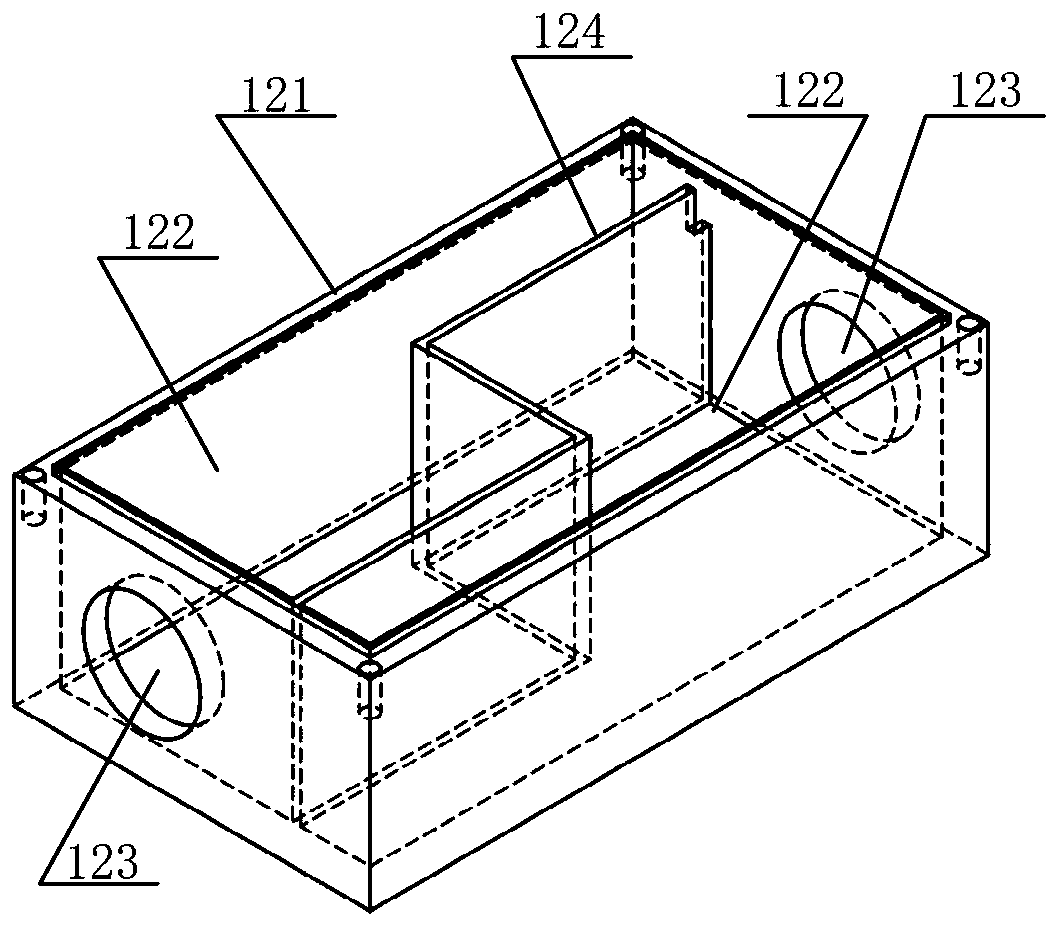

[0075] see Figure 1 to Figure 4 , the present invention provides a filter 1, the filter 1 includes: a helical coil 11, the helical coil 11 includes several twisted pairs, wherein half of the twisted pairs are wound in a clockwise direction, The winding direction of the remaining twisted pairs is counterclockwise, that is, the winding direction of half of the twisted pairs is clockwise, and the winding direction of the other half of the twisted pairs is counterclockwise; the shielding box 12 , the shielding box 12 includes a box body 121 and a cover body 125; wherein, a housing groove 122 is formed in the box body 121, and a channel communicating with the housing groove 122 is formed on the side wall of the box body 121. Holes 123; the spiral coil 11 is located in the receiving groove 122; the cover body 125 is sealed on the box body 121; an adapter, the adapter includes a first adapter 131 and a second adapter 132 wherein, the first adapter 131 is located outside the box bod...

Embodiment 2

[0089] Please combine Figure 1 to Figure 4 refer to Figure 7 , the present invention also provides a method for preparing a filter. The filter prepared by the method for preparing a filter described in this embodiment may be, but not limited to, the filter described in Embodiment 1. The filter The preparation methods include:

[0090] 1) Prepare a helical coil, the helical coil includes several twisted pairs, wherein half of the twisted pairs are wound in a clockwise direction, and the remaining twisted pairs are wound in a counterclockwise direction;

[0091] 2) Provide a shielding box, the shielding box includes a box body and a cover body; wherein, a receiving groove is formed in the box body, and a through hole communicating with the receiving groove is formed on the side wall of the box body; placing the helical coil in the containing groove;

[0092] 3) using an adapter to connect to both ends of the helical coil respectively, so as to lead the helical coil out of t...

Embodiment 3

[0108] Please combine Figure 1 to Figure 4 refer to Figure 8 to Figure 9 , the present invention also provides a test system, the test system may include but not limited to a comprehensive physical property test system (PPMS), the test system may include: a low temperature chamber 2; a dilution refrigerator (not shown), the The dilution refrigerator is located in the low-temperature chamber 2, and the dilution refrigerator includes a high-temperature end 31 and a low-temperature end 32, and the high-temperature end 31 is electrically connected to the low-temperature end 32; the sample to be tested 4, the sample to be tested 4 is located in the low temperature chamber 2; a sample holder 5, the sample holder 5 is located in the low temperature chamber 2, and the sample holder 5 is electrically connected to the sample to be tested 4; the first filter 61, the The first filter 61 is located between the sample holder 5 and the sample to be detected 4, and is electrically connecte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com