Battery production method and battery production device

A manufacturing method and battery technology, applied in secondary battery manufacturing, manufacturing tools, auxiliary devices, etc., can solve problems such as collector foil and wire bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

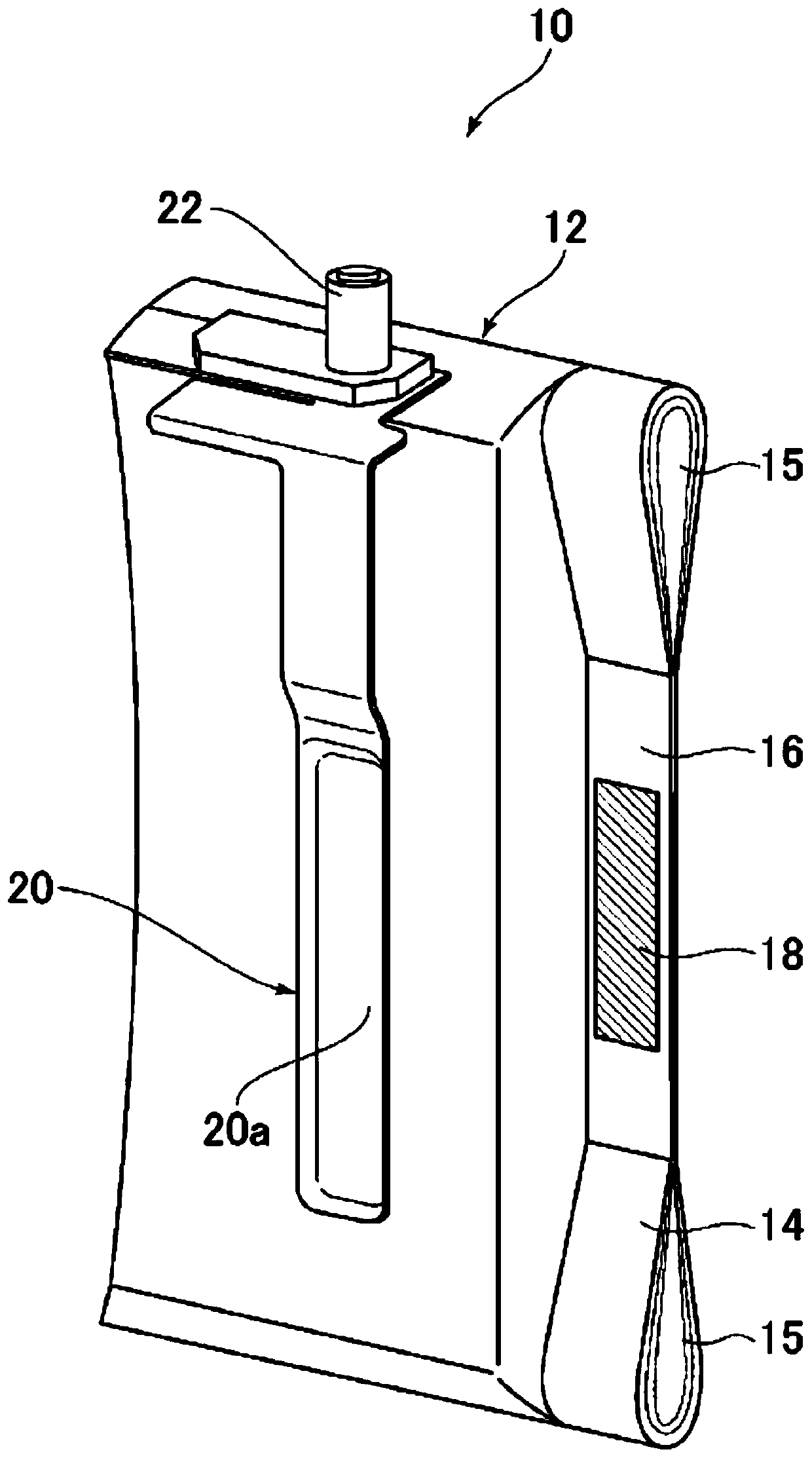

[0025] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0026] 1. Overall structure

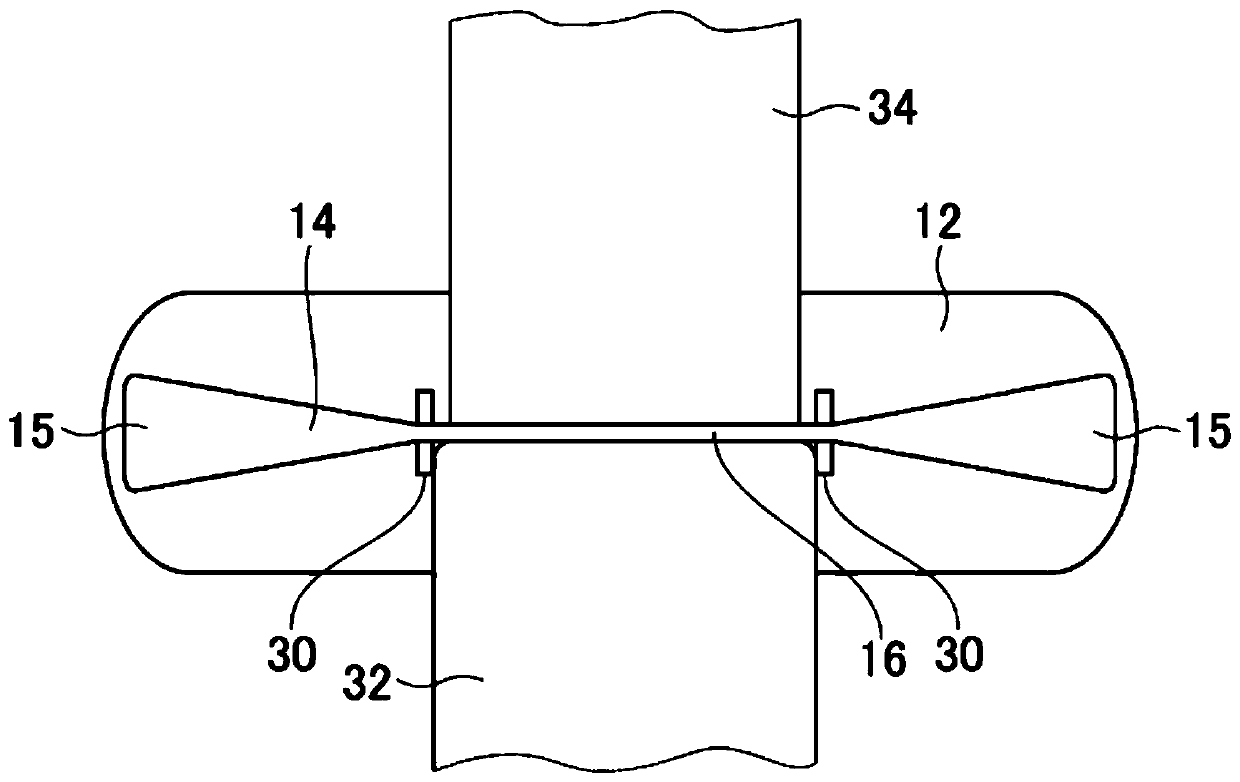

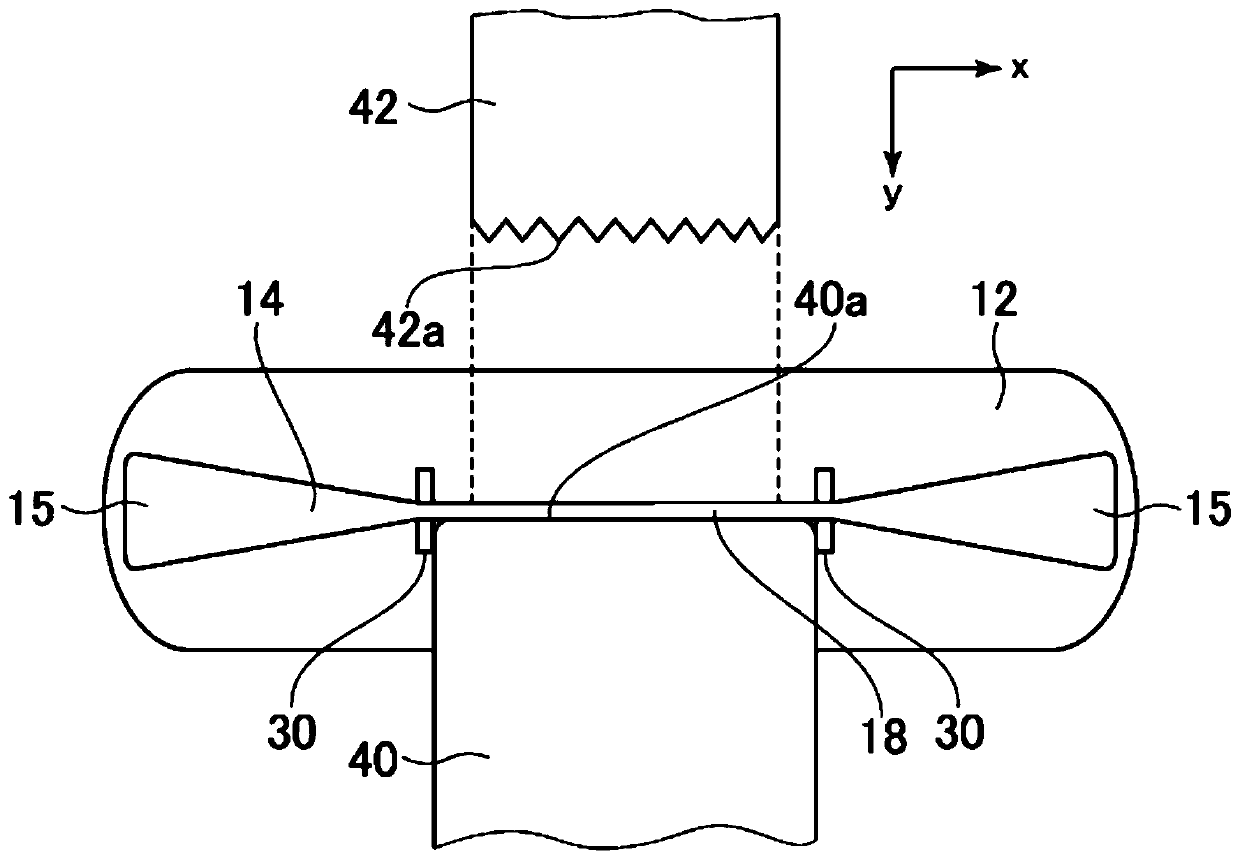

[0027] The battery manufacturing device of the present invention includes a pressurizing unit, a bonding unit, and a judging unit. The pressurizing unit pressurizes predetermined regions of the plurality of collector foils exposed at ends of the electrodes and overlapping each other to form a compressed region in which an interval between adjacent collector foils is reduced.

[0028] The joining unit joins a region inside the compressed region of the plurality of current collector foils by ultrasonic welding using a horn and an anvil to form a joint region in which the plurality of current collector foils are integrated. The judging unit judges whether the bonded area is good or not based on an output waveform representing a temporal change in an output value of the horn. Using the battery manufacturing device of the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com