Method for manufacturing flexible printed circuit board and flexible printed circuit board manufactured by same

一种柔性印刷、电路板的技术,应用在印刷电路制造、印刷电路、印刷电路等方向,能够解决高频信号损失、低介电常数、柔性印刷电路板制造成本增加等问题,达到防止高频信号的损失、介电损耗最小化的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Hereinafter, preferred embodiments of the present invention will be described with reference to the accompanying drawings so that those skilled in the art to which the present disclosure pertains can easily practice the technical idea of the present disclosure. First, when adding reference numerals to components in each drawing, it should be noted that the same components are denoted by the same reference numerals even if they are shown in different drawings. Also, in the following description of the present disclosure, if a detailed description of a known configuration or function may obscure the gist of the present disclosure, the detailed description will be omitted.

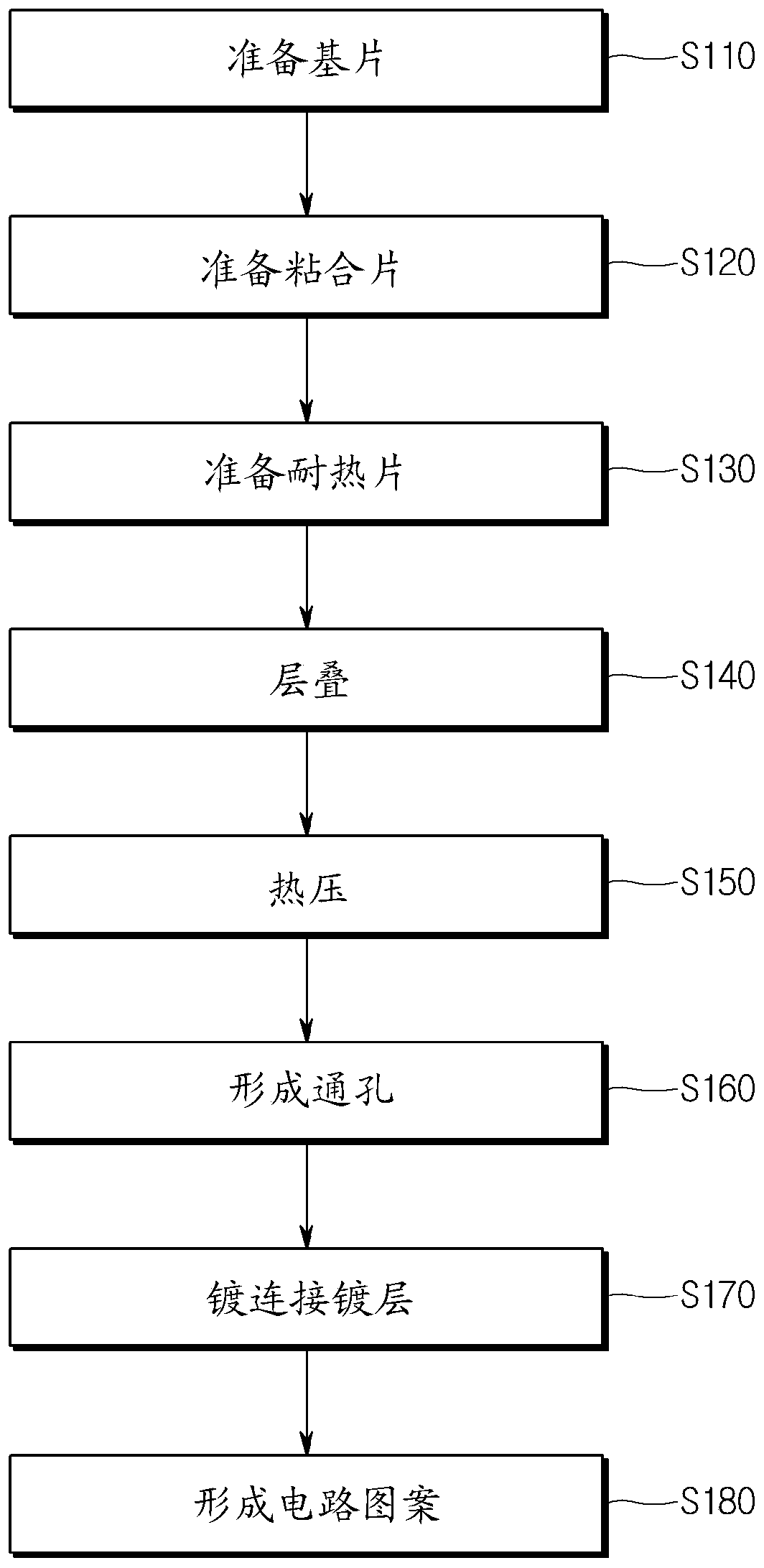

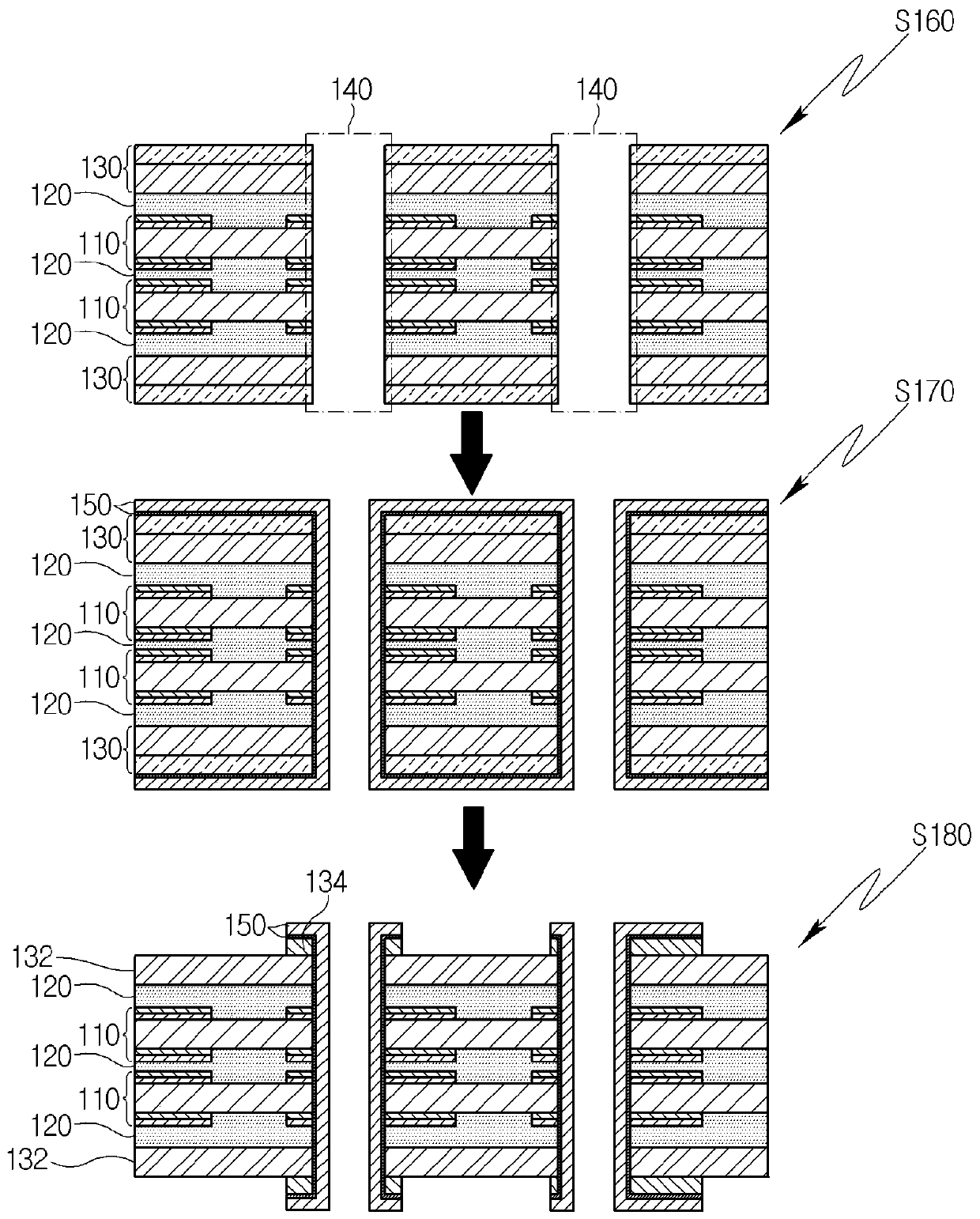

[0049] see Figure 1 to Figure 3 , a method for manufacturing a flexible printed circuit board according to a first embodiment of the present disclosure includes: preparing a substrate 110S110, preparing an adhesive sheet 120S120, preparing a heat-resistant sheet 130S130, laminating the substrate 110,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com