Cu0.2Ni0.8O/SBA-15, production method and method for using Cu0.2Ni0.8O/SBA-15 in combination with persulfate for degrading sulfonamide solution

A persulfate and solution technology, which is applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problems of low degradation efficiency of sulfonamides, and achieve easy storage and transportation, high activity and Stable, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

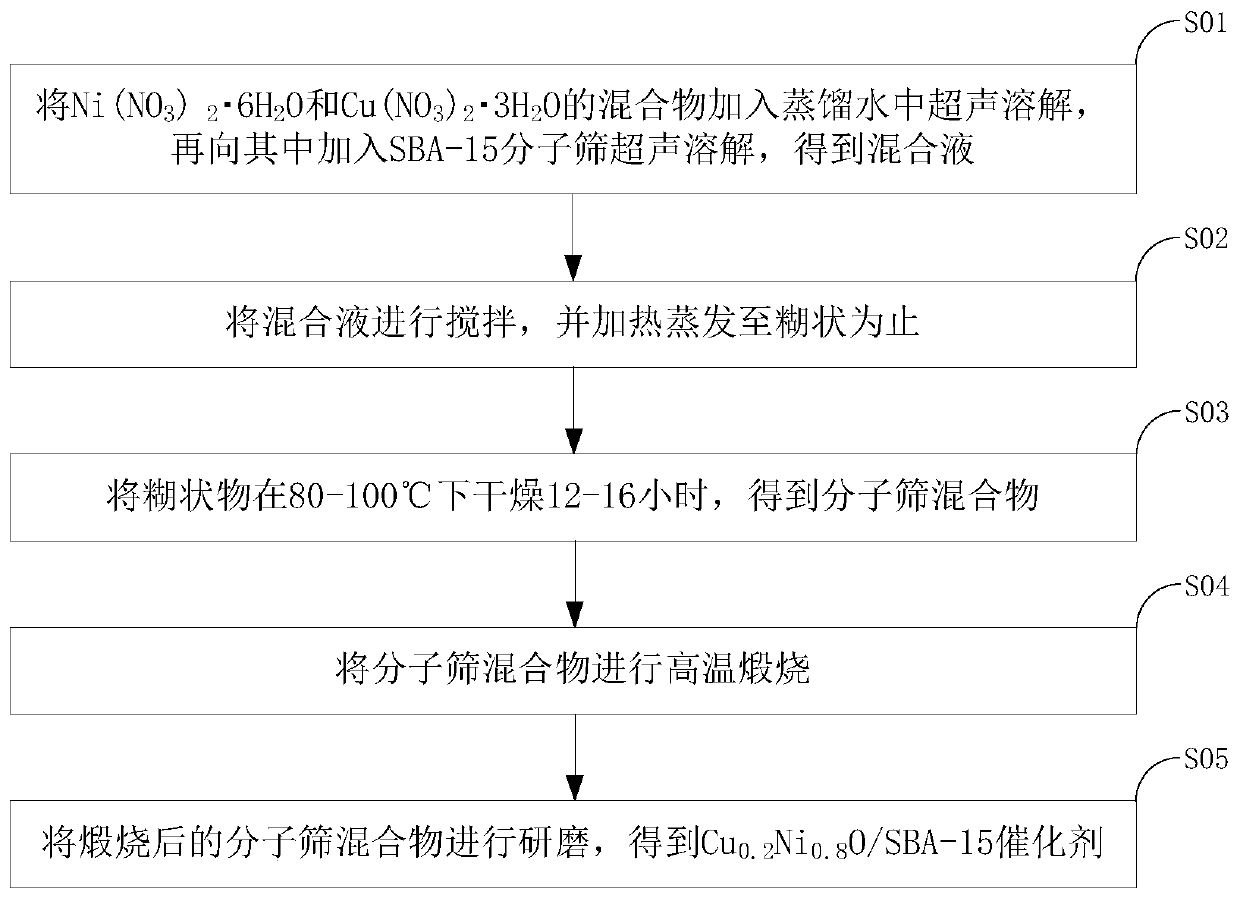

[0063] The embodiment of the application provides a Cu 0.2 Ni 0.8 O / SBA-15 catalyst, the preparation method of the catalyst is:

[0064] S101: Ni(NO) with a mole fraction ratio of 1.1:1 3 ) 2 ·6H 2 O and Cu (NO 3 ) 2 ·3H 2 The O mixture is added to distilled water to dissolve ultrasonically, and then SBA-15 molecular sieve is added to it to dissolve ultrasonically to obtain a mixed solution;

[0065] S102: Stir the above-mentioned mixed liquid, and heat and evaporate until it becomes a paste;

[0066] S103: Dry the above paste at 80°C for 16 hours to obtain a molecular sieve mixture;

[0067] S104: calcining the above-mentioned molecular sieve mixture at a high temperature; the high-temperature calcination conditions are: the calcination temperature is 600°C, the heating rate is 2° / min, and the calcination time is 6 hours;

[0068] S105: Grind the calcined molecular sieve mixture to obtain Cu 0.2 Ni 0.8 O / SBA-15 catalyst.

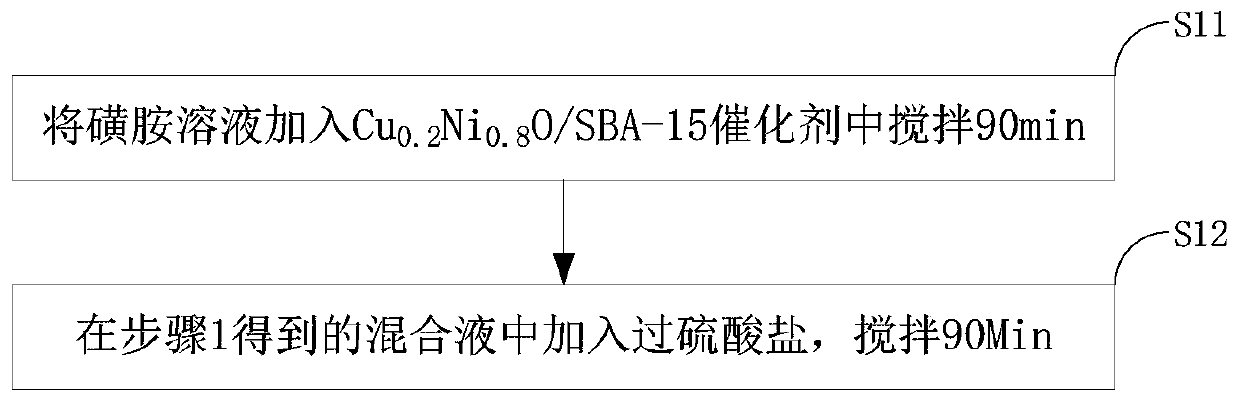

[0069] The embodiment of the application also provides a Cu 0.2 ...

Embodiment 2

[0073] The embodiment of the application provides a Cu 0.2 Ni 0.8 O / SBA-15 catalyst, the preparation method of the catalyst is:

[0074] S201: The ratio of mole fraction is 1.2:1 Ni(NO 3 ) 2 ·6H 2 O and Cu (NO 3 ) 2 ·3H 2 The O mixture is added to distilled water to dissolve ultrasonically, and then SBA-15 molecular sieve is added to it to dissolve ultrasonically to obtain a mixed solution;

[0075] S202: Stir the above-mentioned mixed liquid, and heat and evaporate until it becomes a paste;

[0076] S203: Dry the above paste at 90°C for 14 hours to obtain a molecular sieve mixture;

[0077] S204: calcining the above-mentioned molecular sieve mixture at a high temperature; the high-temperature calcination conditions are: the calcination temperature is 500°C, the heating rate is 2° / min, and the calcination time is 8 hours;

[0078] S205: Grind the calcined molecular sieve mixture to obtain Cu 0.2 Ni 0.8 O / SBA-15 catalyst.

[0079] The embodiment of the application also provides a Cu 0.2 N...

Embodiment 3

[0083] The embodiment of the application provides a Cu 0.2 Ni 0.8 O / SBA-15 catalyst, the preparation method of the catalyst is:

[0084] S301: The ratio of mole fraction is 1.15:1 Ni(NO 3 ) 2 ·6H 2 O and Cu (NO 3 ) 2 ·3H 2 The O mixture is added to distilled water to dissolve ultrasonically, and then SBA-15 molecular sieve is added to it to dissolve ultrasonically to obtain a mixed solution;

[0085] S302: Stir the above-mentioned mixed liquid, and heat and evaporate until it becomes a paste;

[0086] S303: Dry the above paste at 85°C for 15 hours to obtain a molecular sieve mixture;

[0087] S304: calcining the above molecular sieve mixture at a high temperature; the high-temperature calcination conditions are: the calcination temperature is 510°C, the heating rate is 2° / min, and the calcination time is 7.5 hours;

[0088] S305: Grind the calcined molecular sieve mixture to obtain Cu 0.2 Ni 0.8 O / SBA-15 catalyst.

[0089] The embodiment of the application also provides a Cu 0.2 Ni 0.8 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com