Bag manufacturing device for processing of food packaging bag

A bag-making device and bag-packing technology, applied in the field of packaging bag processing, can solve problems such as inaccurate heat-sealing position, and achieve the effects of improving efficiency, reducing deformation and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following is further described in detail through specific implementation methods:

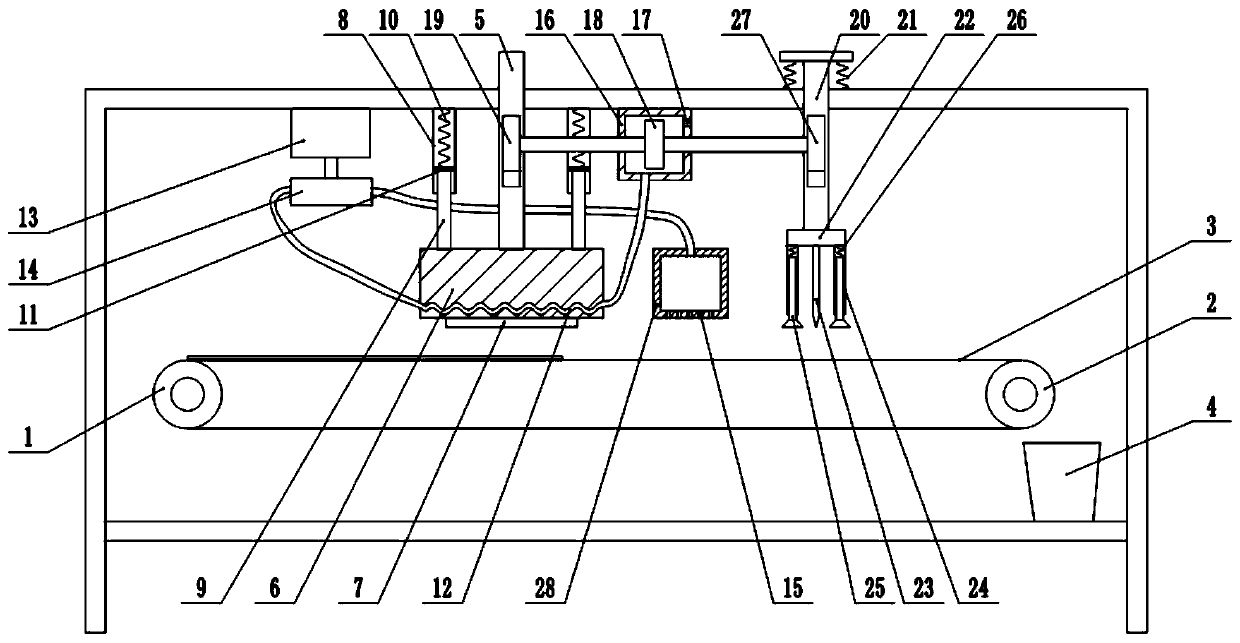

[0023] The reference signs in the drawings of the description include: driving wheel 1, driven wheel 2, chain plate conveyor belt 3, recovery box 4, first rack 5, support plate 6, pressure plate 7, outer sleeve rod 8, inner sleeve rod 9, second An elastic member 10, a limit block 11, a channel 12, an air supply box 13, a vortex tube 14, a ventilation hole 15, an air guide box 16, an exhaust port 17, a turbine 18, a first fan gear 19, a second rack 20, a second rack Two elastic members 21, a base 22, a cutter 23, an outer rod 24, an inner rod 25, a third elastic member 26, a second sector gear 27, and a cold air box 28.

[0024] The embodiment is basically as attached figure 1 Shown:

[0025] A bag-making device for food packaging bag processing includes a frame on which a transfer unit, a heat-sealing unit and a cutting unit are arranged. The transmission unit includes a driving w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com