1-(4-morpholinylphenyl)-1-butanone preparation method

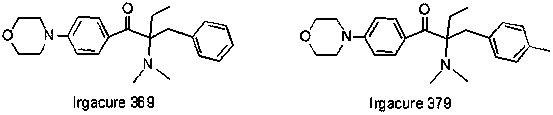

A technology of morpholine phenyl and methyl ethyl ketone, which is applied in the field of preparation of α-aminoacetophenone-based photoinitiator intermediates, can solve the problems of cumbersome post-processing, long reaction time, and dangerous addition of materials, so as to reduce the risk of reaction, The effect of shortening the response cycle and reducing risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: Preparation of 1-(4-morpholine phenyl)-1-butanone

[0026] Dissolve morpholine (336.5g, 4.0mol) in water (360.0g, 20.0mol), then add 1-(4-chlorophenyl)-1-butanone (182.7, 1.0mol), and stir well, Put it into a 1.5L high-pressure reactor, close the reactor, and heat the reaction solution to 210-215°C within 1.5-2 hours, while the pressure in the reactor is also rising, control the pressure in the reactor at about 20bar, and keep warm for 8 hours Then cool down and crystallize, shake off the filter, wash the filter cake with water, and dry to obtain 222.8 g of beige crystals with a purity of 99.1% and a melting point of 65.5-66.5°C.

[0027] After centrifugation, the filtrate was collected for morpholine recovery, and 40.0 g of sodium hydroxide was added under stirring. After the addition, all fractions of the morpholine and water mixture were collected by heating distillation, and directly applied mechanically.

Embodiment 2

[0028] Embodiment 2: Preparation of 1-(4-morpholine phenyl)-1-butanone

[0029] Dissolve morpholine (261.0g, 3.0mol) in water (360.0g, 20.0mol), then add 1-(4-chlorophenyl)-1-butanone (182.7, 1.0mol), and stir well, Put it into a 1.5L high-pressure reactor, close the reactor, and heat the reaction solution to 210-215°C within 1.5-2 hours, while the pressure in the reactor is also rising, control the pressure in the reactor at about 20bar, and keep warm for 10 hours Then cool down and crystallize, shake off the filter, wash the filter cake with water, and dry to obtain 220.8 g of beige crystals with a purity of 99.3% and a melting point of 65.5-66.5°C.

Embodiment 3

[0030] Example 3: Preparation of 1-(4-morpholine phenyl)-1-butanone

[0031] Dissolve morpholine (217.5g, 2.5mol) in water (360.0g, 20.0mol), then add 1-(4-chlorophenyl)-1-butanone (182.7, 1.0mol), and stir well, Put it into a 1.5L high-pressure reactor, close the reactor, and heat the reaction liquid to 210-215°C within 1.5-2 hours, while the pressure in the reactor is also rising, control the pressure in the reactor at about 20bar, and keep warm for 28 hours Then cool down and crystallize, shake off the filter, wash the filter cake with water, and dry to obtain 186.0 g of beige crystals with a purity of 93.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com