High-antibacterial low-emission automotive modified polypropylene composite material and preparation method thereof

A composite material, polypropylene technology, applied in the field of polypropylene, to achieve the effects of large specific surface area, excellent mechanical properties, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

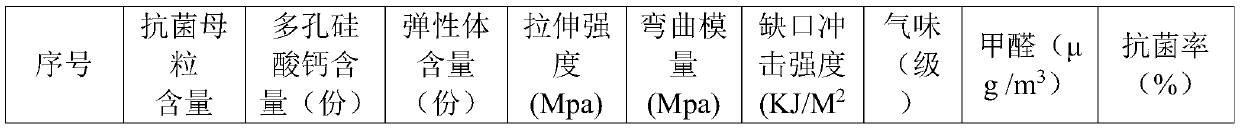

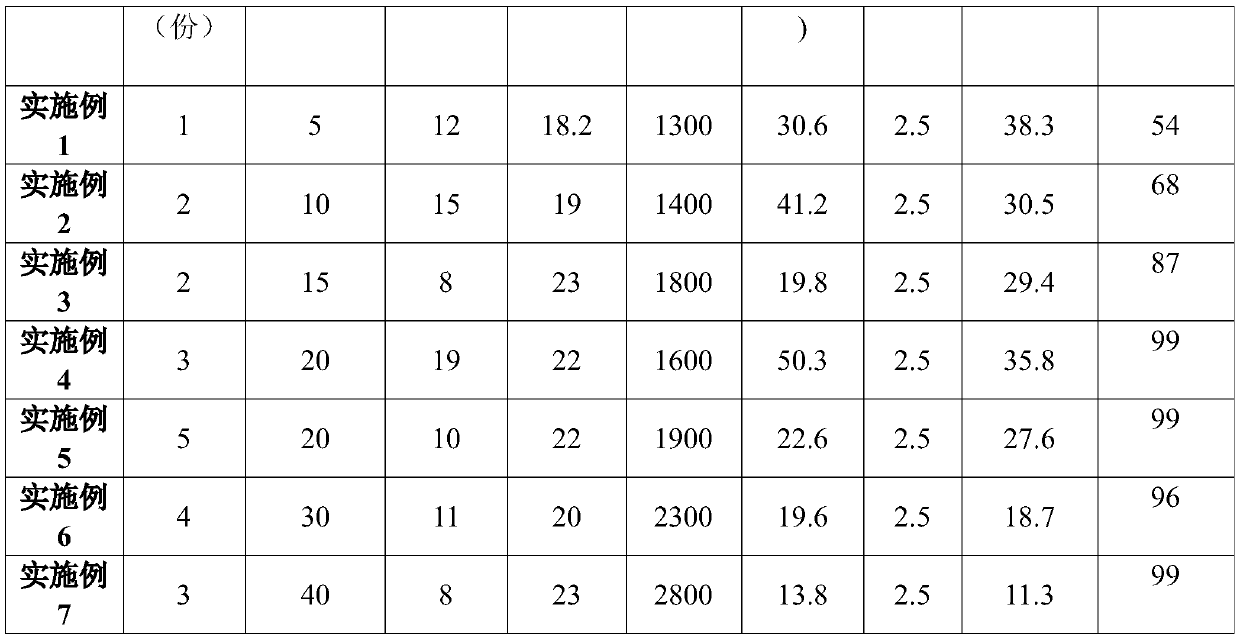

Examples

Embodiment 1

[0039] (1) Preparation of antibacterial functional masterbatch:

[0040] In parts by weight, flow velocity is 76 parts of polypropylene of 50g / min; 20 parts of nano zinc dioxide; 1 part of compatibilizer methyl glycidyl ether grafted PP (GMA-PP), 2 parts of calcium stearate , together into a high-speed mixer and mixed evenly, then added to a twin-screw extruder, melted, extruded, cooled, and pelletized to prepare antibacterial functional masterbatches.

[0041] The processing temperatures in zones I to X of the twin-screw extruder are 108°C, 190°C, 200°C, 200°C, 215°C, 220°C, 220°C, 225°C, 230°C, and 230°C in sequence. The rotational speed of the main screw is 550r / min, and the temperature of the water tank is 37°C.

[0042](2) High antibacterial, low emission polypropylene composite material and its preparation: in parts by weight, 1 part of antibacterial functional masterbatch prepared in step (1) and 80 parts of polypropylene with a flow rate of 60g / min, porous silicon Ca...

Embodiment 2

[0045] (1) Preparation of antibacterial functional masterbatch:

[0046] In parts by weight, the flow velocity is 65 parts of polypropylene of 50g / min; 30 parts of nano zinc dioxide; 2 parts of compatibilizer methyl glycidyl ether graft PP (GMA-PP), zinc stearate and hard 3 parts of the calcium fatty acid mixture are added together into a high-speed mixer and mixed evenly, then added into a twin-screw extruder, melted, extruded, cooled, and pelletized to prepare antibacterial functional masterbatches through the twin-screw extruder.

[0047] The processing temperatures in zones I to X of the twin-screw extruder are 108°C, 190°C, 200°C, 200°C, 215°C, 220°C, 220°C, 225°C, 230°C, and 230°C in sequence. The rotational speed of the main screw is 550r / min, and the temperature of the water tank is 37°C.

[0048] (2) High antibacterial, low emission polypropylene composite material and its preparation: in parts by weight, 2 parts of the antibacterial functional masterbatch prepared i...

Embodiment 3

[0051] (1) Preparation of antibacterial functional masterbatch:

[0052] In parts by weight, the flow velocity is 68 parts of polypropylene of 60g / min; 30 parts of nanometer zinc dioxide; 1 part of compatibilizer methyl glycidyl ether grafted PP (GMA-PP), 1 part of calcium stearate , together into a high-speed mixer and mixed evenly, then added to a twin-screw extruder, melted, extruded, cooled, and pelletized to prepare antibacterial functional masterbatches.

[0053] The processing temperatures in zones I to X of the twin-screw extruder are 108°C, 190°C, 200°C, 200°C, 215°C, 220°C, 220°C, 225°C, 230°C, and 230°C in sequence. The rotational speed of the main screw is 550r / min, and the temperature of the water tank is 37°C.

[0054] (2) High antibacterial, low emission polypropylene composite material and its preparation: by weight, 2 parts of the antibacterial functional masterbatch prepared in step (1) and 75 parts of polypropylene with a flow rate of 60g / min, porous silico...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com