Formula of anti-aging composite resin suitable for pultrusion process

A technology of composite material and pultrusion process, which is applied in the field of polymer material resin, can solve the problems of easy aging and short service life of composite materials, achieve the effect of strong anti-ultraviolet performance, reduce production cost, and delay the process of photoaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

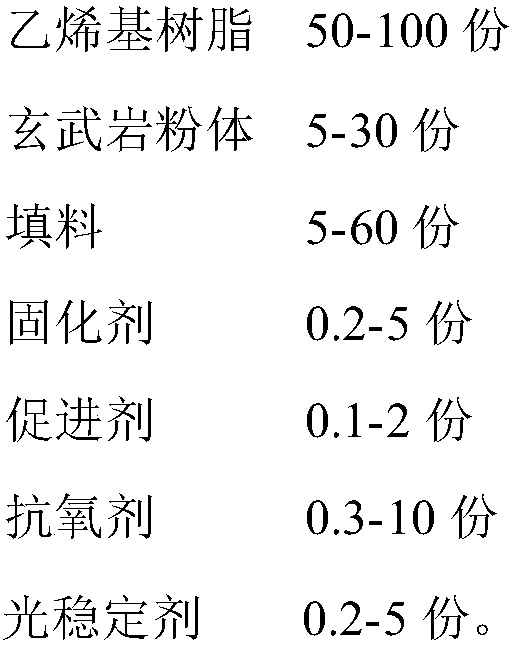

[0017] An aging-resistant composite material resin formulation suitable for pultrusion, comprising the following components by weight:

[0018]

[0019]

[0020] Among them, the particle size of the basalt powder is 500 mesh.

[0021] Preparation of pultrusion glue: After adding the components of Example 1 into the mixing tank, mix them evenly to form pultrusion glue.

Embodiment 2

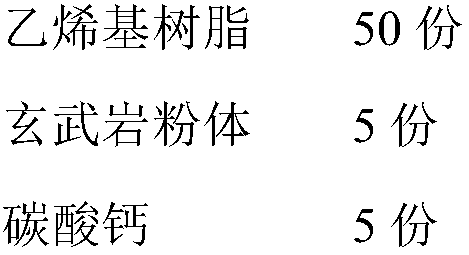

[0023] An aging-resistant composite material resin formulation suitable for pultrusion, comprising the following components by weight:

[0024]

[0025] Among them, the particle size of the basalt powder is 550 mesh.

[0026] Preparation of pultrusion glue: After adding the components of Example 2 into the mixing tank, mix them evenly to form pultrusion glue.

Embodiment 3

[0028] An aging-resistant composite material resin formulation suitable for pultrusion, comprising the following components by weight:

[0029]

[0030] Among them, the particle size of the basalt powder is 600 mesh.

[0031] Preparation of pultrusion glue: After adding the components of Example 3 into the mixing tank, mix them evenly to form pultrusion glue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com