Breathable and cool type non-woven fabric for vehicle seat cushion and preparing method of non-woven fabric

A technology for car seat cushions and non-woven fabrics, applied in textiles and papermaking, devices for coating liquid on the surface, fiber treatment, etc., can solve the problems of non-woven fabric surface deformation, high energy consumption, uneven heating, etc., and it is not easy to achieve Produces, breathable, not easily tolerated effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

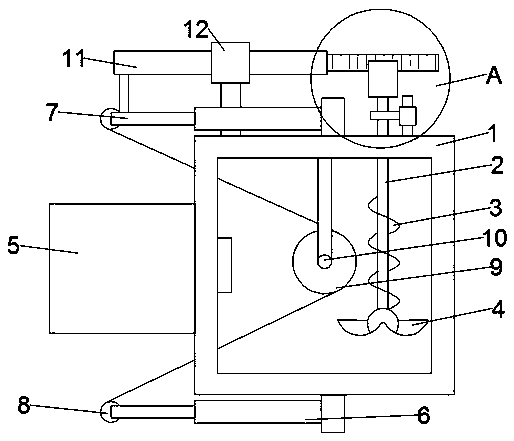

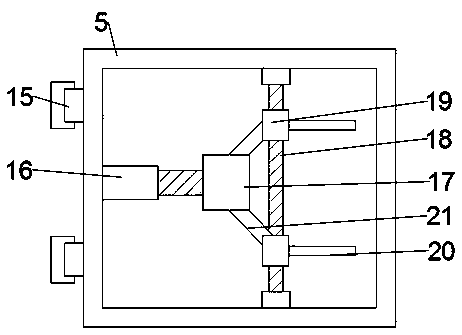

[0021] see Figure 1~3 , in an embodiment of the present invention, a drying device for non-woven fabric production, including a housing 1, a heat conduction chamber 5, a first cylinder 7 and a roller 9, the upper surface of the housing 1 is fixedly installed with the first cylinder 7, the first The left end of the cylinder 7 is equipped with a fixed pulley 8, and the bottom of the housing 1 is provided with a first stop rod 6. The first stop rod 6 is tightly connected with the housing 1 through bolts, and the left end of the first stop rod 6 is installed with a fixed pulley. 8. A roller 9 is installed inside the housing 1, and both sides of the roller 9 are fixedly connected with the first connecting rod 10, and the end of the first connecting rod 10 away from the roller 9 is welded to the upper wall of the housing 1, and the fixed pulley 8 and the roller 9 are connected by non-woven fabric, the left side of the housing 1 is provided with a heat conduction chamber 5, and the ...

Embodiment 2

[0026] A kind of preparation method of the air-permeable and dry type car seat cushion nonwoven fabric based on the nonwoven fabric production drying device described in embodiment 1, the steps are as follows:

[0027] 1) Weigh the raw materials required for the production of non-woven fabrics, then put the raw materials into the mixer, stir and mix for 3 hours, and discharge to obtain the first mixture;

[0028] 2) Add ten times the volume of water to the first mixture, then add vinylbisstearamide, stir and mix to obtain the second mixture, and then dry the second mixture at a drying temperature of 120°C;

[0029] 3) Take the non-woven fabric base material, soak the base material in sodium bicarbonate solution, after soaking, apply the second mixture on the non-woven fabric base material, and dry it naturally for one hour, then put the non-woven fabric Put it into the casing 1 for drying treatment, and then get final product.

Embodiment 3

[0031] A breathable and dry non-woven fabric for car seat cushions based on the preparation method of the breathable and dry car seat cushion described in Example 2.

[0032] The non-woven fabric prepared by the invention has strong air permeability, high safety, less toxic and side effects, and less tolerance, is more easily accepted by consumers, and has broad market prospects.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com