Low-stiffness balanced pipeline compensation device for heating pipe network

A technology of heating pipe network and compensation device, which is applied to expansion compensation device for pipelines, pipeline protection, pipeline damage/wear prevention, etc. Problems such as normal work accidents, large additional force or additional displacement, etc., can eliminate the cumulative installation error and stress, avoid sunlight aging, and reduce the overall size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described with reference to the drawings and specific embodiments, but the present invention is not limited to these embodiments.

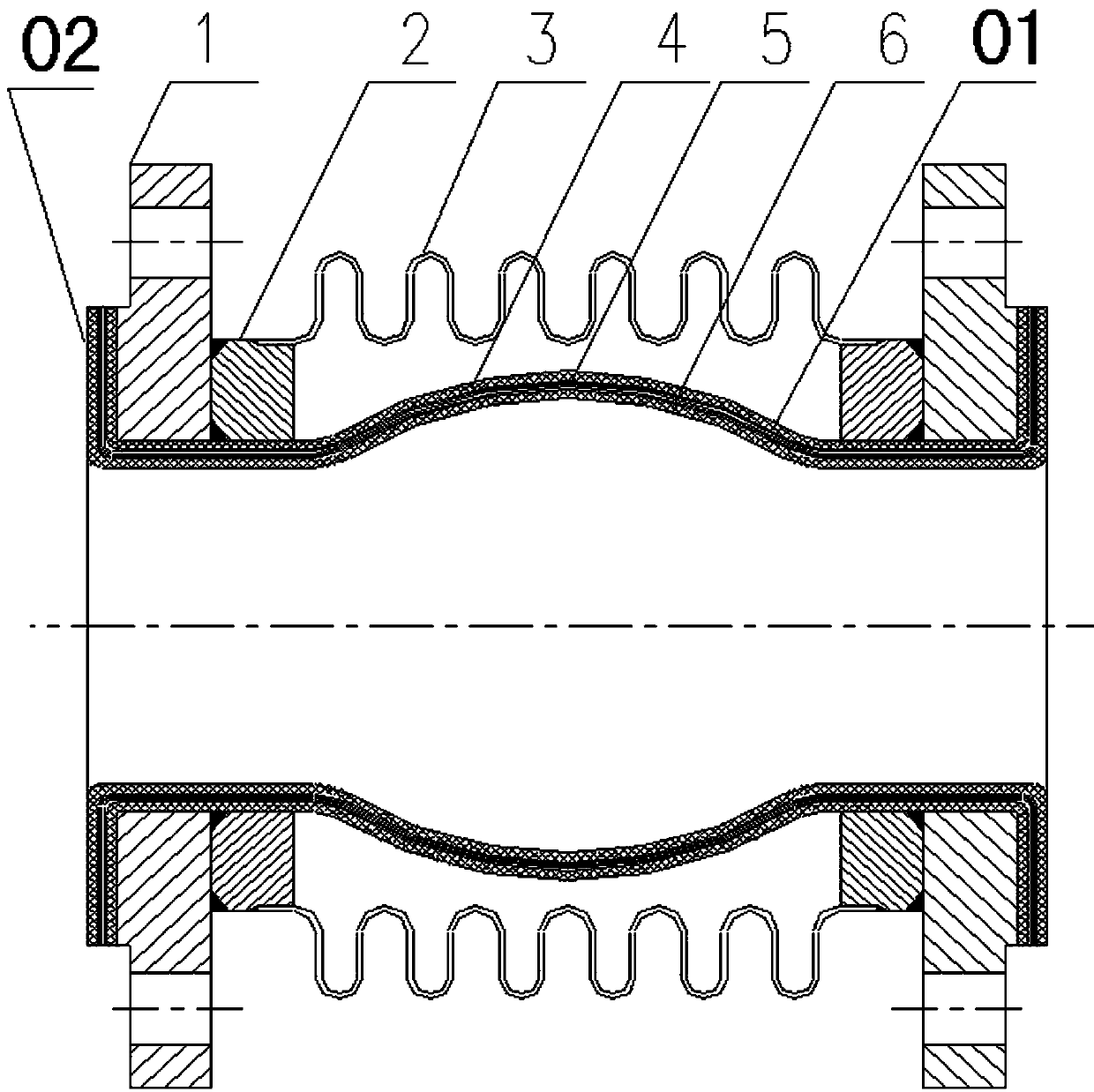

[0022] Such as figure 1 As shown, a low-rigidity balanced pipeline compensation device for heating pipe network, including flange 1, backing ring 2, metal protection bellows 3 and arc-shaped flexible joint; the arc-shaped flexible joint is composed of outer rubber layer 4 , The skeleton layer 5 and the inner rubber layer 6 are integrally formed. The middle part of the arc-shaped flexible connecting pipe bulges around to form a curved part 01, and its two ends are folded to form a flanging part 02. The edge is folded outward, the inner side of the flange 02 at both ends is connected with the outer end surface of the flange 1, and the flange 02 is attached to the flange 1, and the connection is tightened by the living flange, and the flange can also be welded on Flange.

[0023] A backing ring 2 and a metal protecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com