Heat transfer pipe and cracking furnace

A heat transfer tube and cracking furnace technology, applied in the field of heat transfer tubes and cracking furnaces, can solve the problems of high thermal stress, increased pressure drop, large fluid resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

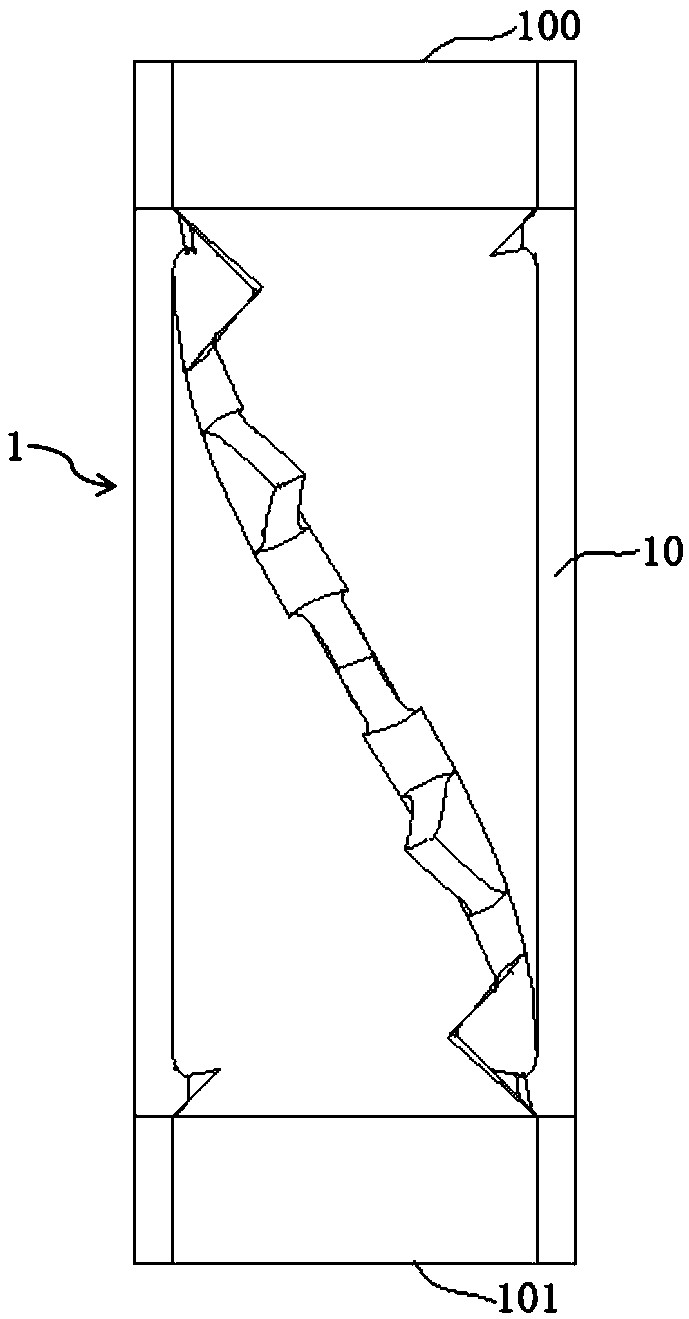

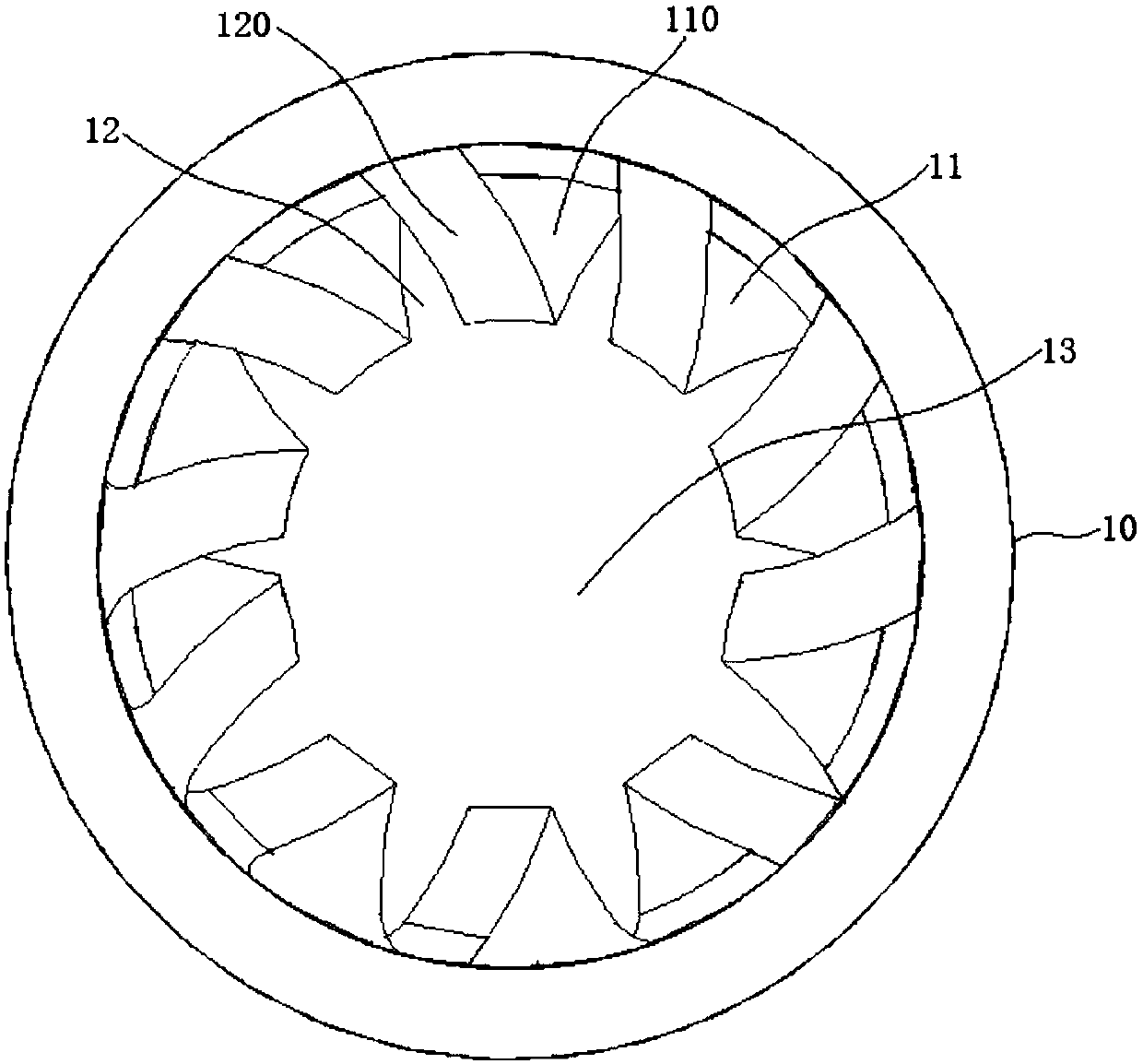

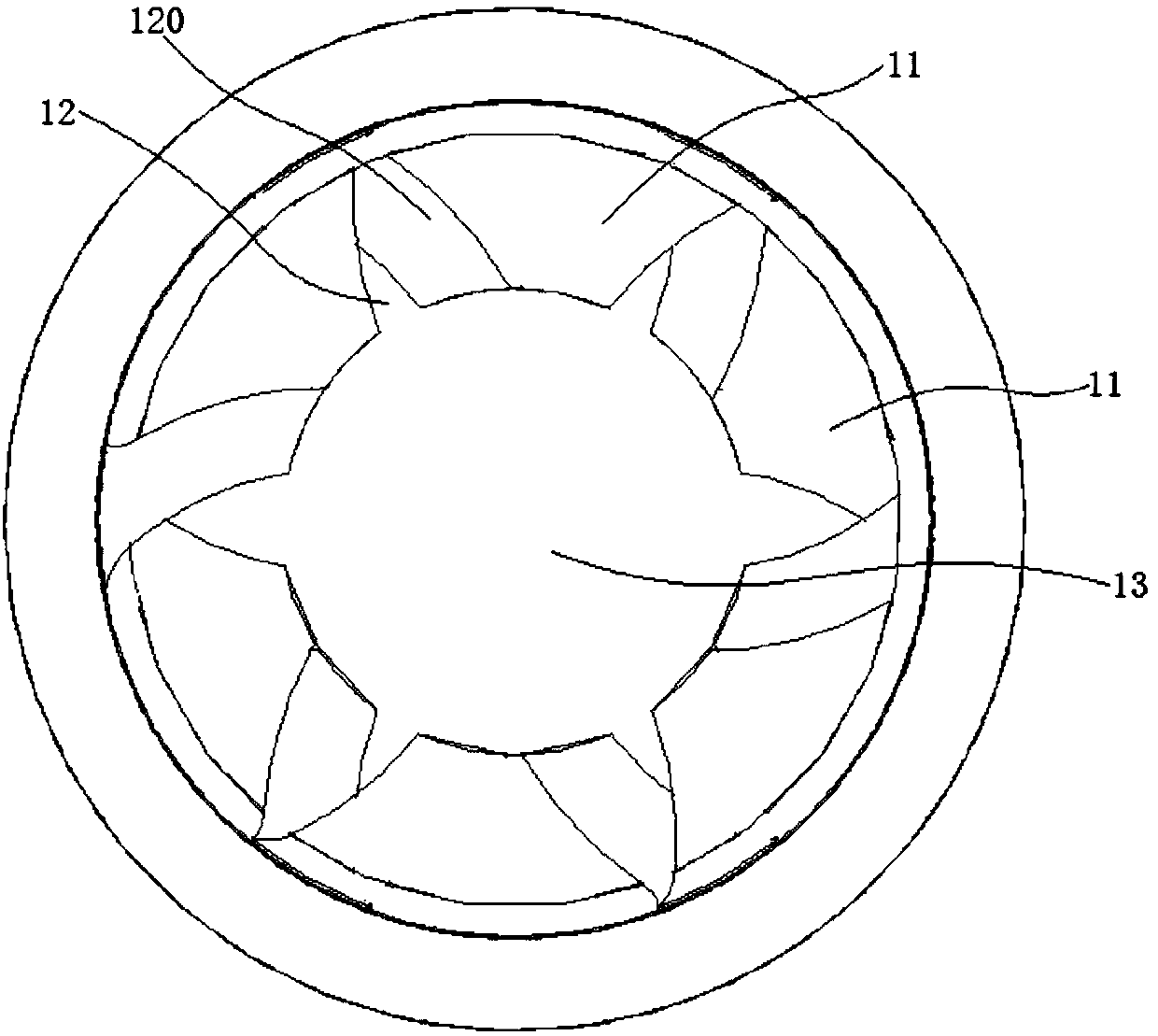

[0038] A plurality of radiant furnace tube assemblies are arranged in the radiant chamber of the cracking furnace, and heat transfer tubes 1 are arranged in three of the radiant furnace tube assemblies, and each radiant furnace tube assembly is provided with Two heat transfer tubes 1 arranged at intervals, the inner diameter of each heat transfer tube 1 is 70mm, in each radiation furnace tube assembly, the axial length of the radiation furnace tube between two adjacent heat transfer tubes 1 is 50 times the inner diameter of the heat transfer tube 1. The structure of each heat transfer tube 1 is: two twisted sheets 11 are arranged on the inner surface of the tube body 10, each twisted sheet 11 includes a plurality of fins 110, and the plurality of fins 110 are along the axial direction of the tube body 10 Extending in a spiral shape, the length of each rib 110 along the direction of spiral extension is 10mm, and each rib 110 is as figure 2 It is roughly triangular in shape, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rotation angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com