Method for measuring shaft force of bolt

A bolt shaft and bolt technology, which is applied in the field of threaded fastener testing, can solve problems such as complicated operation and inability to use assembly measurement, and achieve the effects of good interchangeability, low cost, and convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

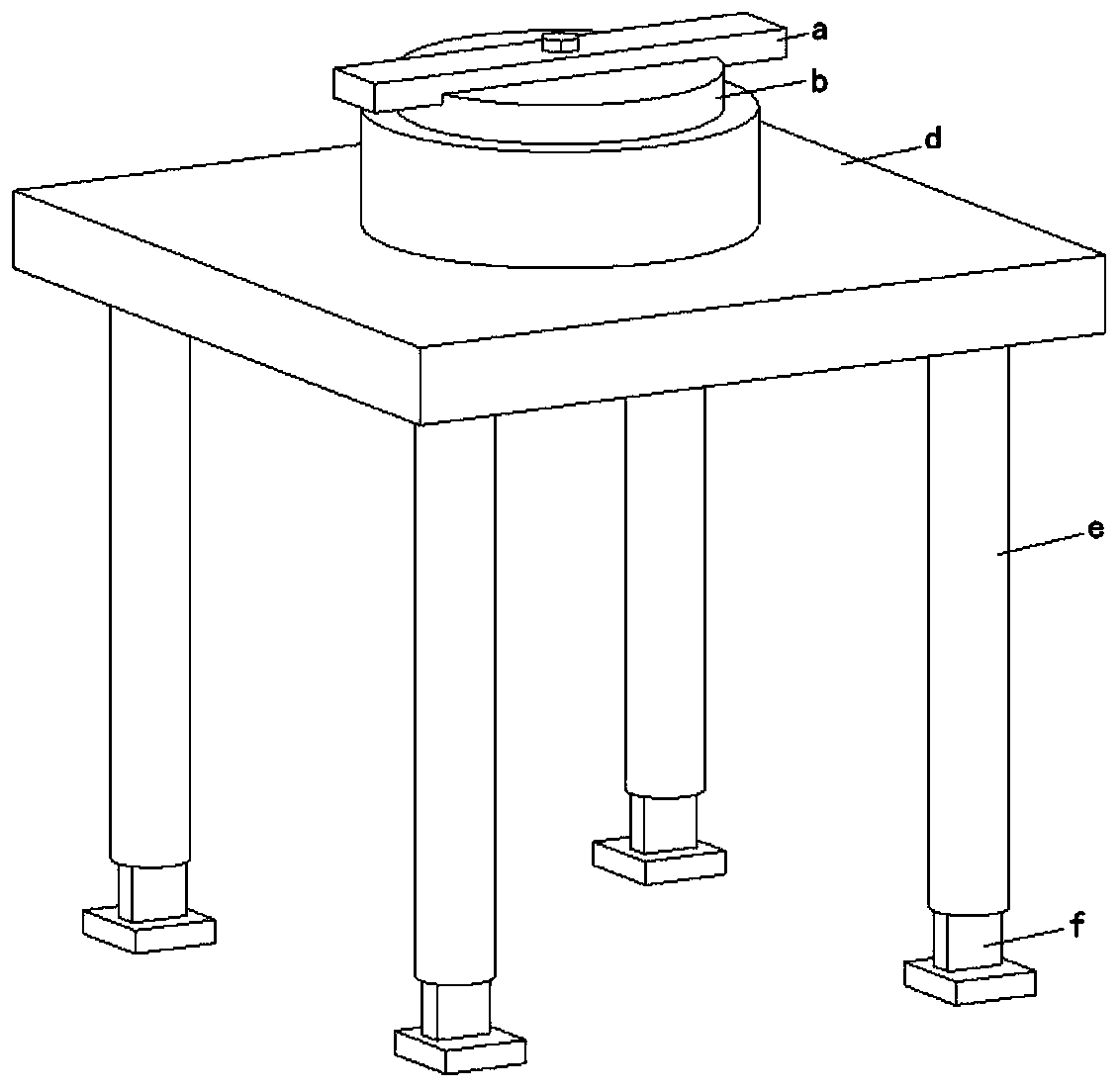

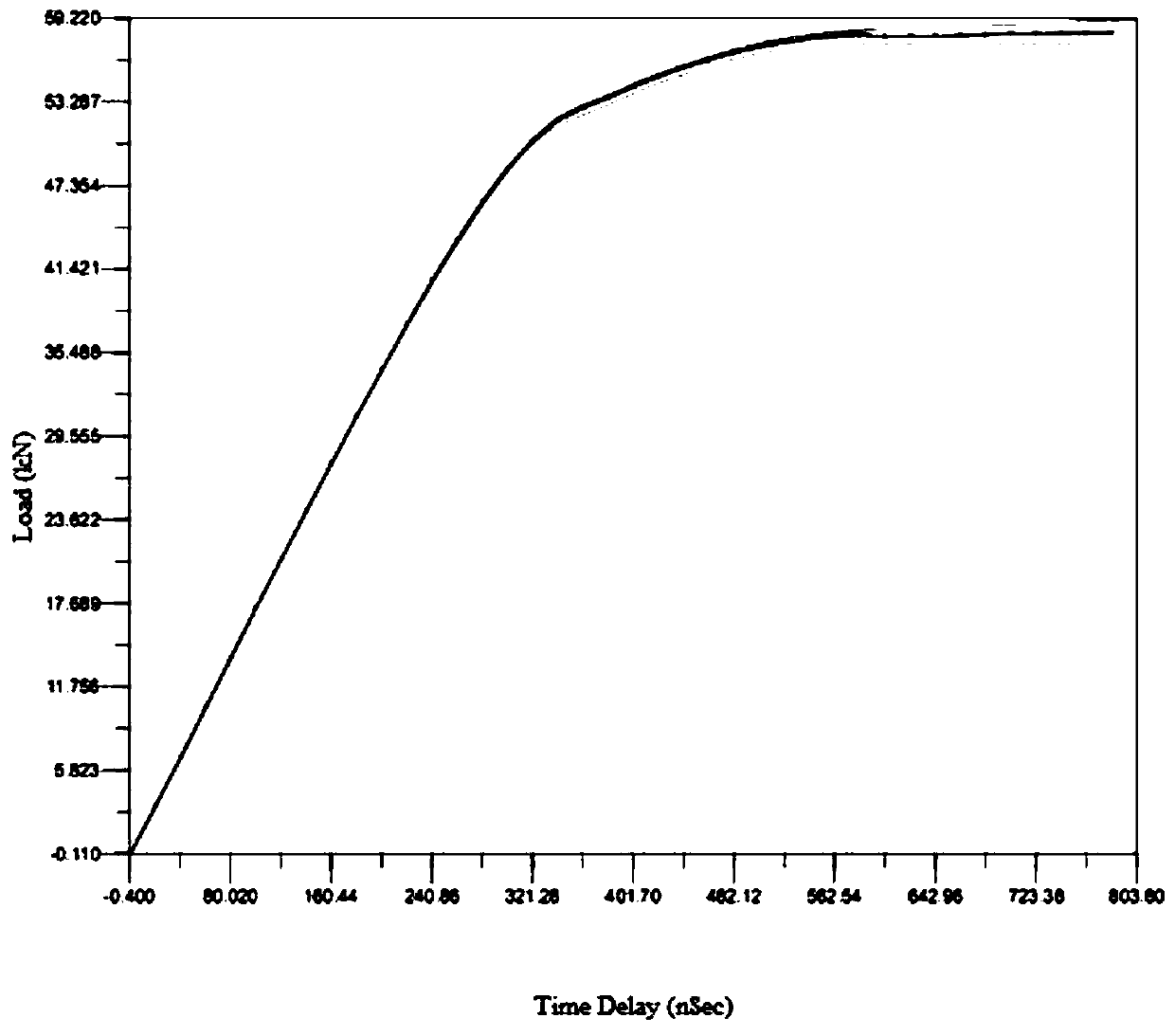

[0072] In the process of product development, it is necessary to design the assembly torque according to the axial force or verify the known assembly torque for the connection of important positions in the product development process. Taking the M10×1.5 bolt as an example, the method of the present invention is used to measure the actual assembly axial force. The test includes the following steps:

[0073] 1) Install the tooling fixture of the calibration bolt, thread one end of the support rod e into the internal thread hole of the shape block f, and insert it into the test bench or iron floor to fix it; and screw the other end of the support rod e into the support through the thread Inside the plate d and securely tightened and fixed;

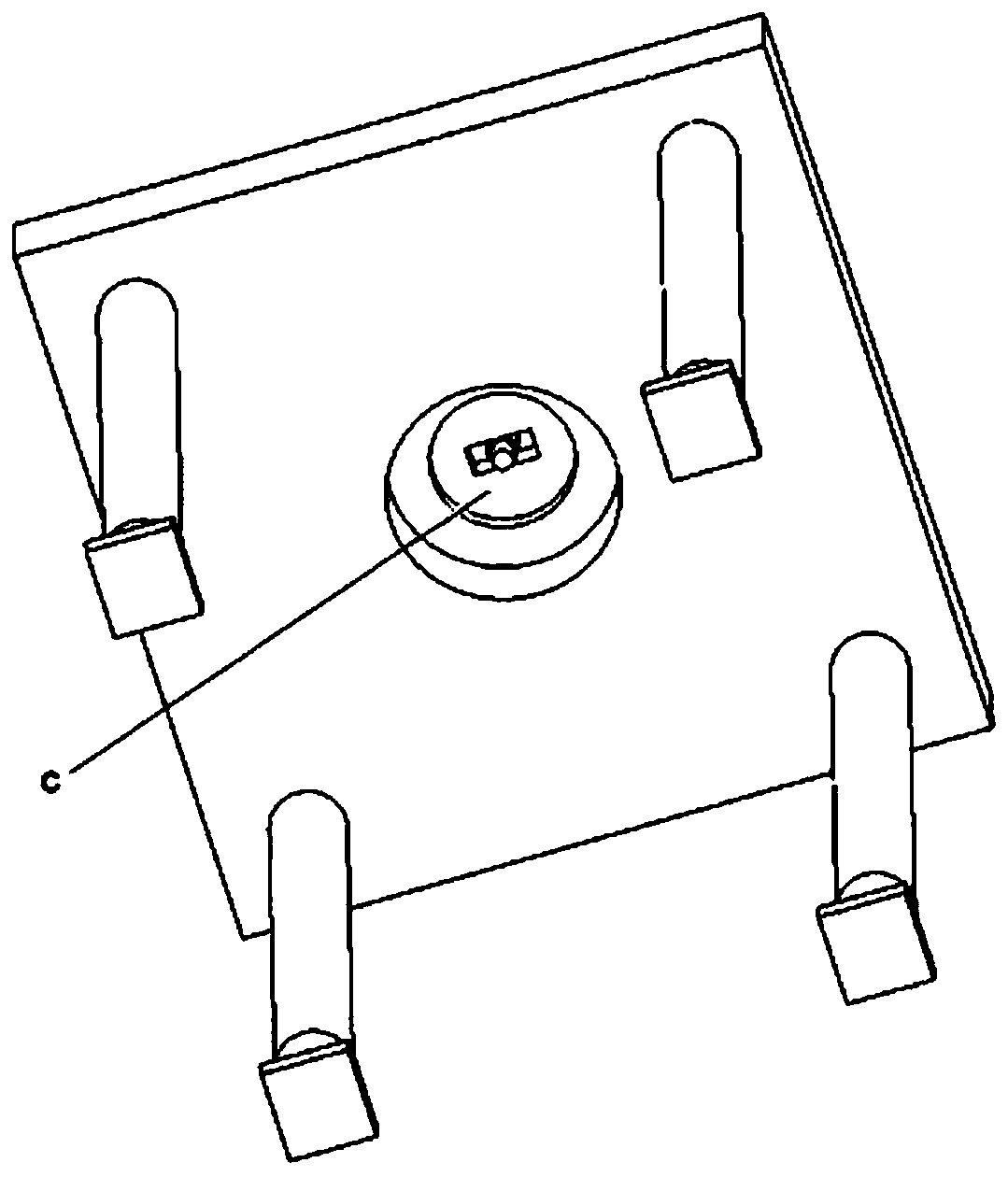

[0074] After connecting the nut clamp c and the chuck b to the axial force sensor with screws or other reliable connection methods, connect the axial force sensor to the support plate d;

[0075] Place the adjusting washer a in the groove in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com