Full-automatic fish killing machine capable of automatically clearing scales and internal organs of fish

An automatic cleaning and fully automatic technology, which is applied in fish processing, fish cleaning/descaler, poultry/fish slaughtering/stunning, etc., can solve the problems of high cost, cumbersome operation, high labor intensity, etc., to achieve convenient operation and overcome Defects, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

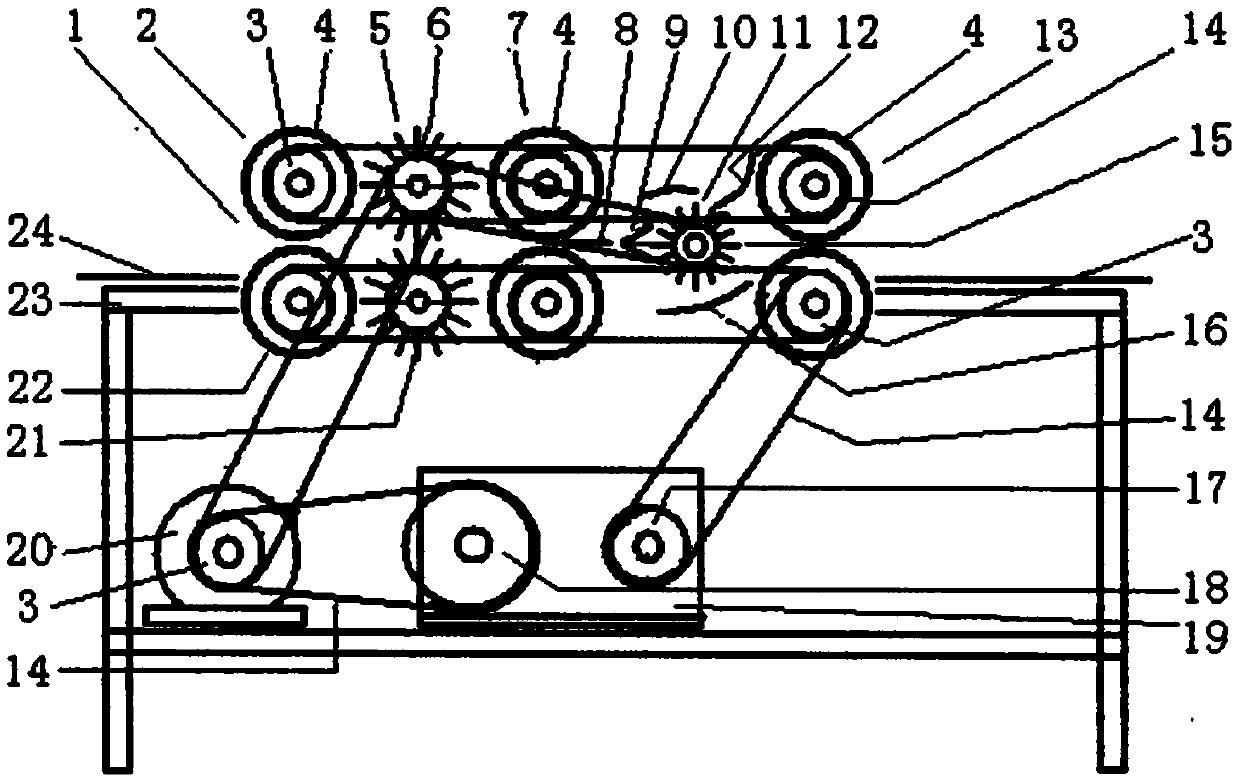

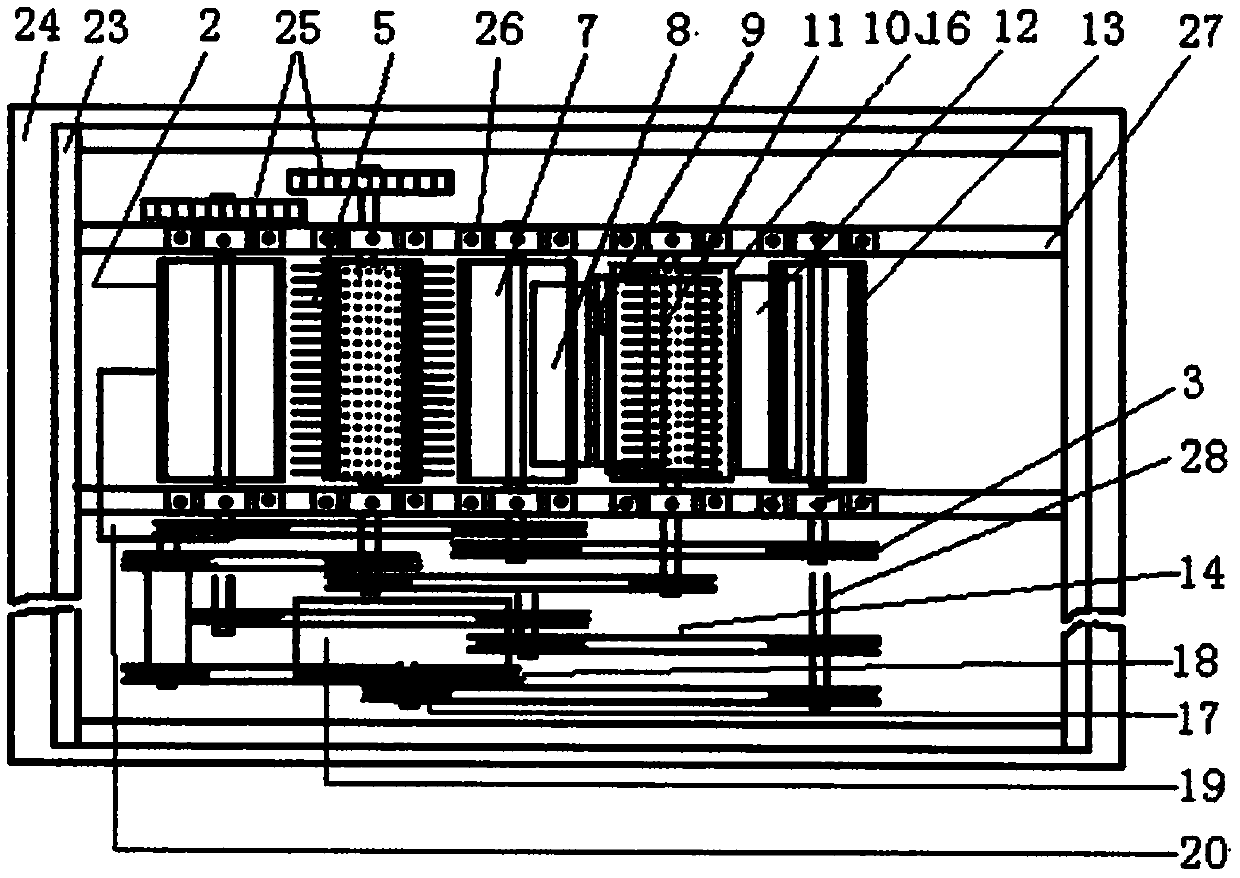

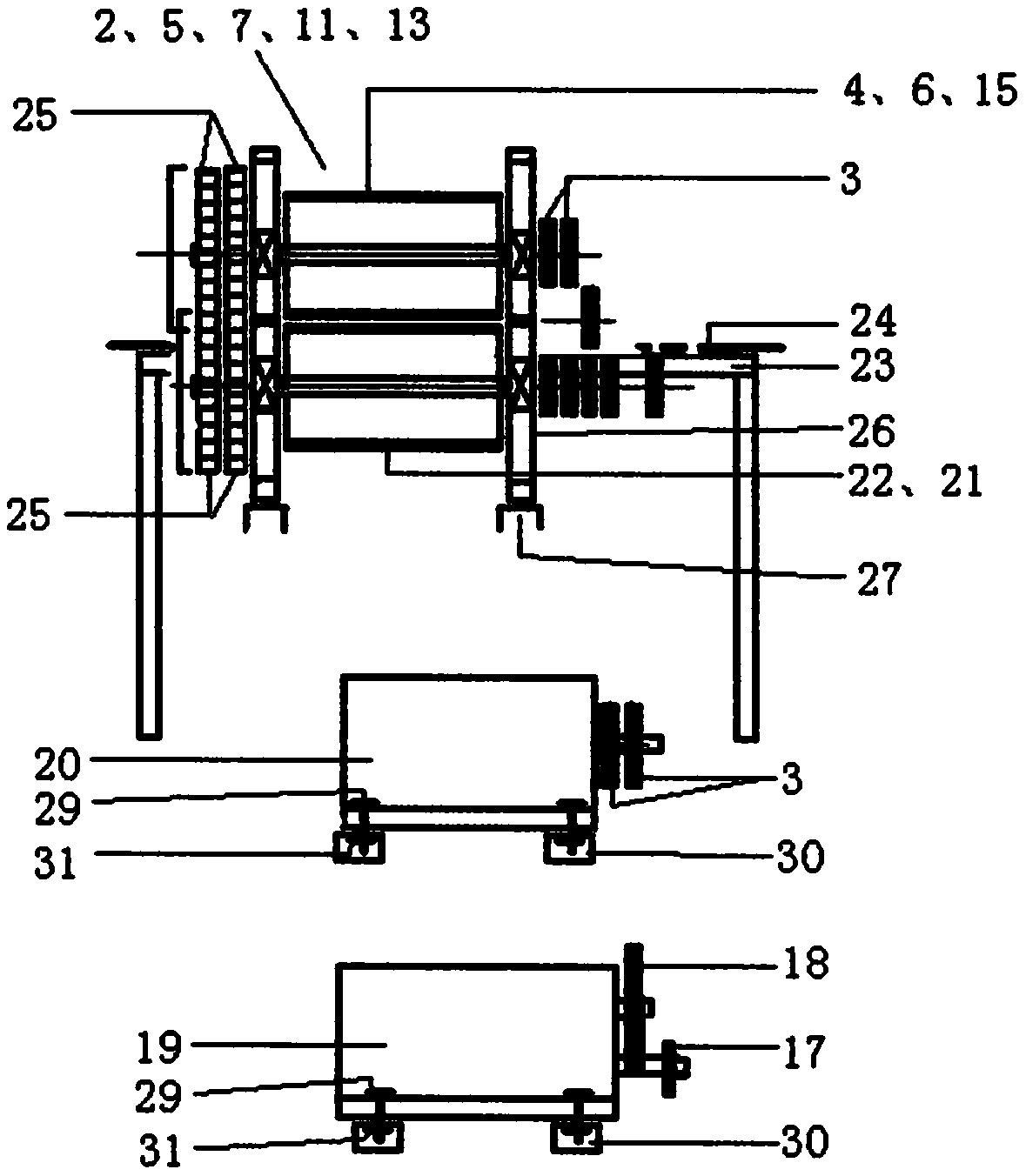

[0033] Below in conjunction with accompanying drawing of description, the present invention is further described:

[0034] A fully automatic fish killing machine that automatically cleans fish phosphorus and viscera, according to the attached figure 1 , 2 , 3, mainly including the first conveying wheel assembly 2, the second conveying wheel assembly 7, the third conveying wheel assembly 13 and the fish scale scraping wheel assembly 5, vibrating knife 8, which constitute the conveying wheel assembly 1 Brush wheel assembly 11 and herringbone guide plate 9, retaining plate 10, traction plate 16, dredging plate 12, frame 23, table panel 24, motor 20, gear reduction box 19, two pairs of gears 25 and several sprockets 3 , the chain 14 is characterized in that: the frame 23 is provided with a table panel 24, and the table panel 24 is provided with a conveying wheel assembly 2, The second conveying wheel assembly 7, the conveying wheel assembly 1 composed of the third conveying whee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com