Automatic assembly production line process of wheel-mounted brake discs

An automatic assembly and brake disc technology, applied in the complete process field, can solve the problems of high labor intensity, low production efficiency, error-prone, etc., and achieve the effect of high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings, but it is not limited thereto. Any modification or equivalent replacement of the technical solution of the present invention without departing from the spirit and scope of the technical solution of the present invention should be covered by the present invention. within the scope of protection.

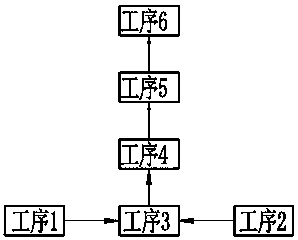

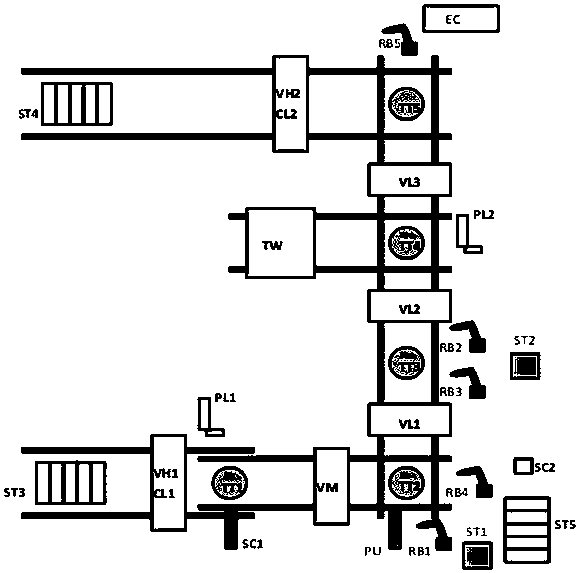

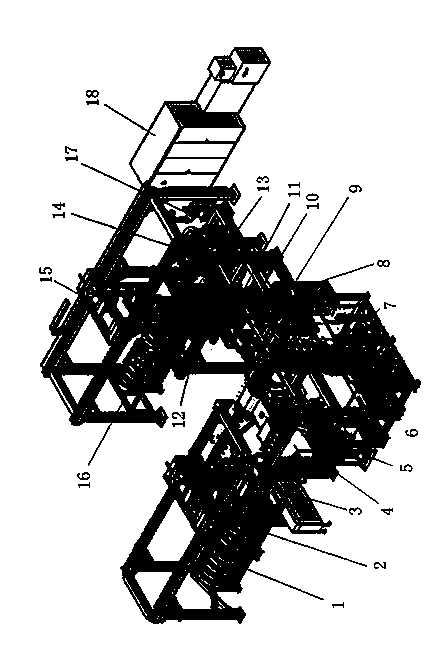

[0019] The invention provides a production line process for automatic assembly of wheel-mounted brake discs, the process flow of which is as follows: figure 1 As shown, the composition and function are as figure 2 shown, according to figure 1 assembly process and figure 2 The 3D data model for the design of the plane layout such as image 3 shown. The following is an introduction to the assembly process of the wheel and the two brake discs in order of assembly:

[0020] (1) Read the ID number of the lower brake disc and upload it to the host comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com