Well test flange knocking hammer

A technology for striking hammers and flanges, which is applied in the field of Christmas tree flange disassembly tools, and can solve the problems of unfavorable carrying and operation, hurting people, and small contact surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

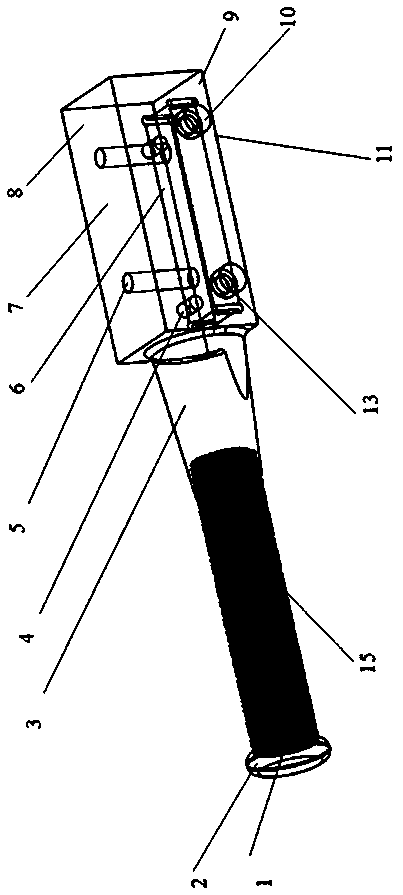

[0032] As a preferred embodiment of the present invention, it discloses a well testing flange knocking hammer, which is mainly composed of a hammer handle 1, a steel hammer head 8 and a copper hammer head 9, the steel hammer head 8 is fixedly connected with the hammer handle 1, the bottom surface of the steel hammer head 8 is provided with a groove 6, and the top surface of the copper hammer head 9 is provided with a boss 12 matched with the groove 6, and the boss 12 is embedded in the recess In the groove 6 and fixed by screws 13, the steel tup 8 and the copper tup 9 are connected as one.

Embodiment 2

[0034] As the best embodiment of the present invention, it discloses a well testing flange knocking hammer, which is mainly composed of a hammer handle 1, a steel hammer head 8 and a copper hammer head 9, and the steel hammer head 8 It is fixedly connected with the hammer handle 1, the bottom surface of the steel hammer head 8 is provided with a groove 6, and the top surface of the copper hammer head 9 is provided with a boss 12 matched with the groove 6, and the boss 12 is embedded in the groove 6 and fixed by screws 13 so that the steel tup 8 and the copper tup 9 are integrated.

[0035] Hammer handle 1 is provided with knurling 15 to increase frictional force for the outer surface of cylindrical structure, and the end face is provided with anti-slip circular boss 2, and hammer handle 1 is longer even if slipping back is not easy to injure finger.

[0036] The lower end of the hammer handle 1 is provided with a rigidly connected steel hammer head 8, which is in the shape of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com