Wood cutting device for forestry engineering

A cutting device and wood technology, applied in the direction of clamping device, feeding device, wood processing equipment, etc., can solve the problems of limited application scope, wood offset, user injury, etc., to solve the problem of relatively limited application scope and smooth cutting , to avoid the effect of scrapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

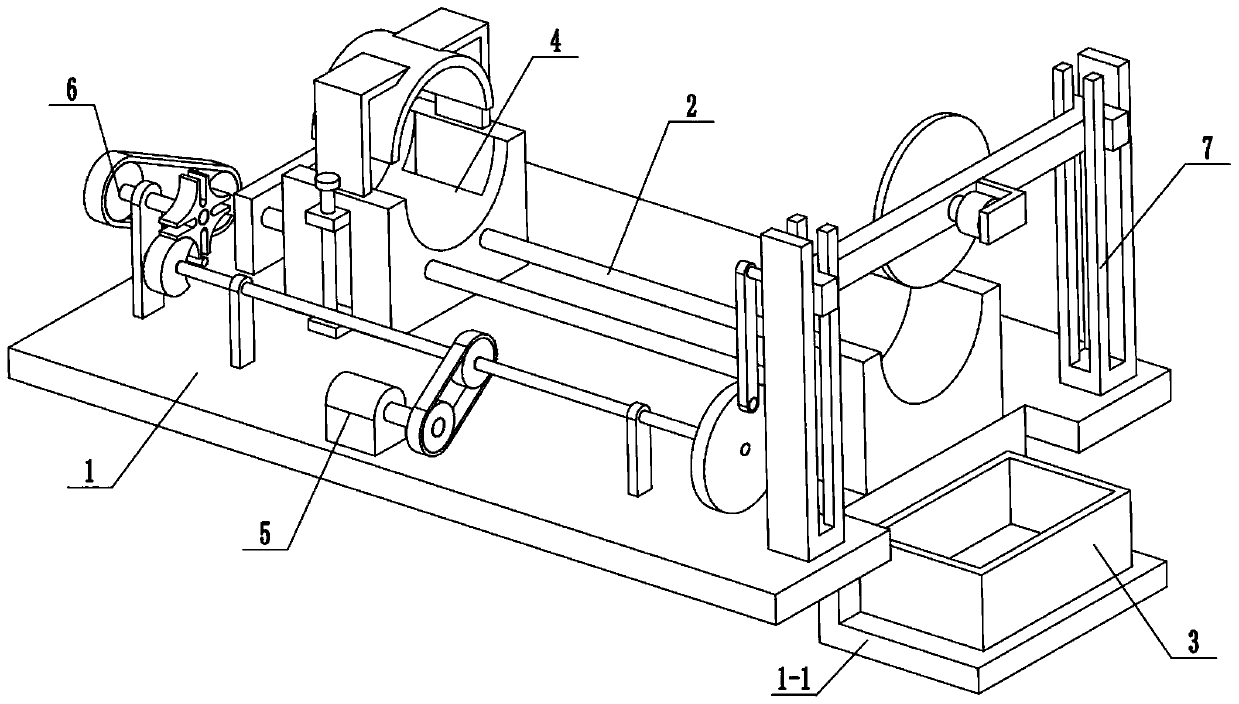

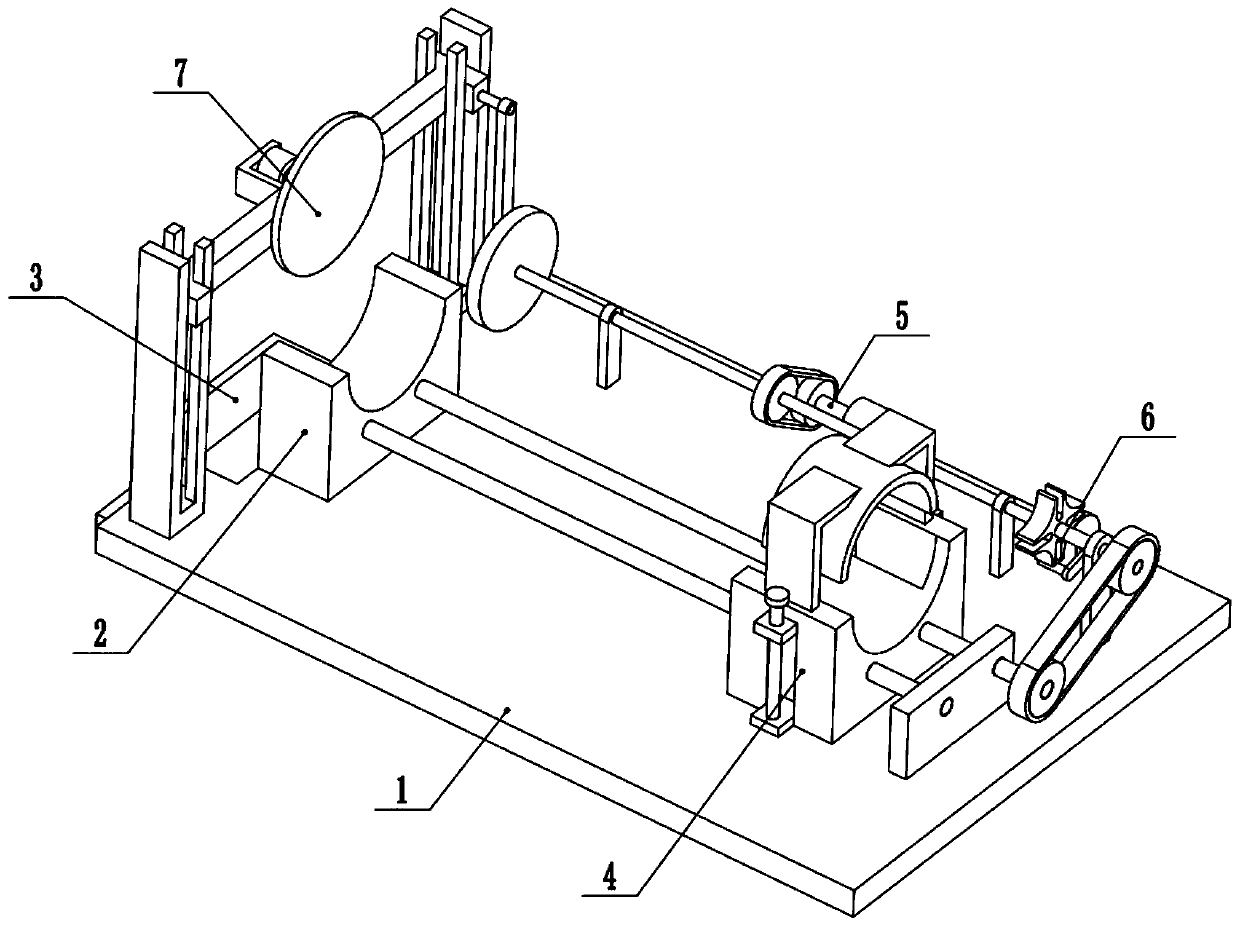

[0031] Combine below Figure 1-11Description of this embodiment, a wood cutting device for forestry engineering, including a base 1, a feeding slide 2, a wood collection box 3, a wood fixing slide 4, a power unit 5, an intermittent feeding mechanism 6 and a cutting assembly 7, the The middle part of the right end of the base 1 is provided with a rectangular through groove, the L-shaped seat plate 1-1 is fixedly connected in the rectangular through groove, the wood collection box 3 is placed on the L-shaped seat plate 1-1, and the feeding slide 2 is fixedly connected to the On the base 1, the wood collection box 3 is located below the right end of the feed slide 2, the wood fixed slide 4 is connected to the feed slide 2, the power unit 5 is fixedly connected to the front end of the base 1, the power unit 5 and the cutting assembly 7 Through the belt drive connection, the cutting assembly 7 is fixedly connected to the right end of the base 1, the intermittent feeding mechanism 6...

specific Embodiment approach 2

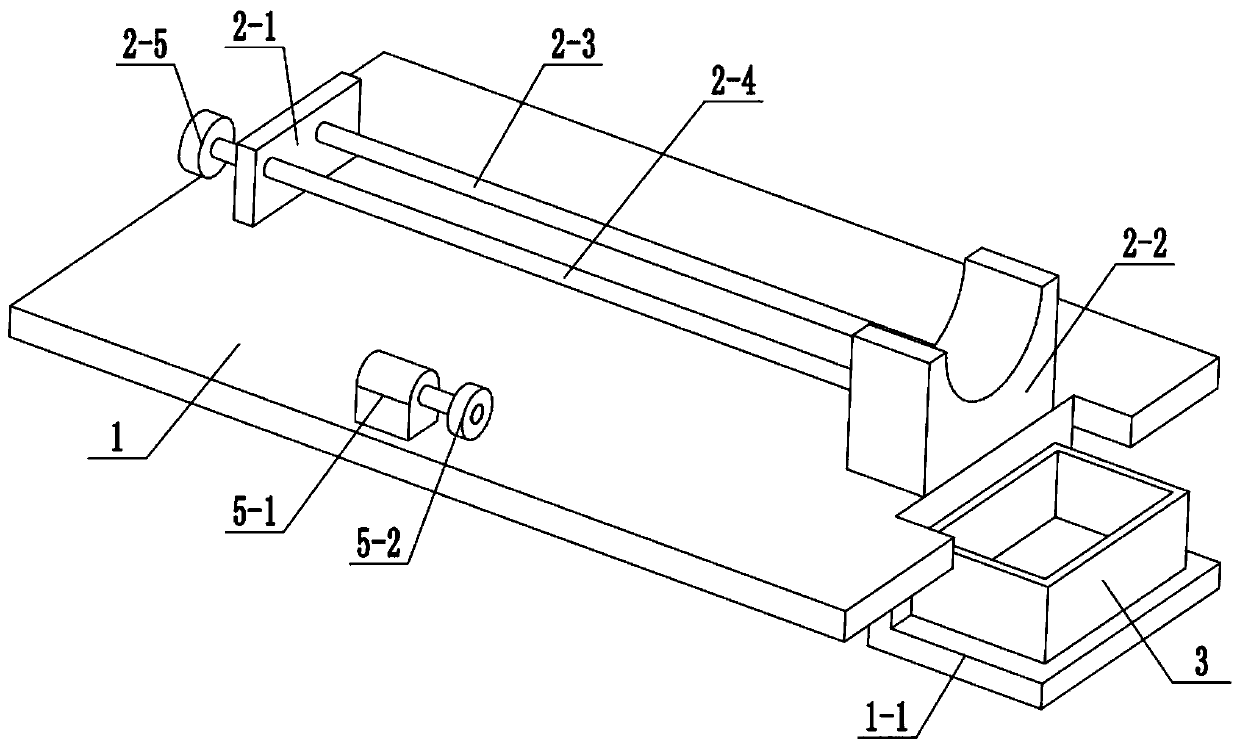

[0033] Combine below Figure 1-11 To illustrate this embodiment, the feed slide 2 includes a side plate 2-1, a wood support seat 2-2, a guide rod 2-3, an external threaded rod 2-4 and a drive pulley 2-5; the side plate 2- 1 and the wood support seat 2-2 are respectively fixedly connected to the left and right ends of the base 1, the two ends of the guide rod 2-3 are respectively fixedly connected to the side plate 2-1 and the wood support seat 2-2, and the external threaded rod 2- The two ends of 4 are respectively connected to the side plate 2-1 and the wood support seat 2-2 through the belt seat bearing rotation, and the transmission pulley 2-5 is fixedly connected to the left end of the external threaded rod 2-4, and the transmission pulley 2-5 is connected to the intermittent feeder. The feeding mechanism 6 is connected by belt transmission; the top surface of the wood support seat 2-2 is provided with a semicircular groove; the wood fixing slide 4 includes a lower fixing ...

specific Embodiment approach 3

[0035] Combine below Figure 1-11 To illustrate this embodiment, the power device 5 includes a motor I5-1 and a driving pulley 5-2; the motor I5-1 is fixedly connected to the front end of the base 1, and the output shaft of the motor I5-1 is fixedly connected to the driving pulley 5-2. 2. The driving pulley 5-2 is connected to the cutting assembly 7 through a belt drive. When the power device 5 is in use, the motor I5-1 is connected to the power supply and the control switch through a wire and turned on, the motor I5-1 drives the driving pulley 5-2 to rotate around its own axis, and the driving pulley 5-2 drives the cutting assembly 7 jobs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com