Storage pump energy saving detection control instrument and working method thereof

A technology of detection control and control instrument, which is applied in the energy saving and control of metallurgical pneumatic ash conveying, storage pump energy saving detection and control instruments, mines, and electric power fields. It can solve the problems of wasting compressed air and energy, inapplicability, and high consumption of compressed air. Achieve the effects of energy saving and service life improvement, avoid dust removal efficiency, and improve ash conveying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

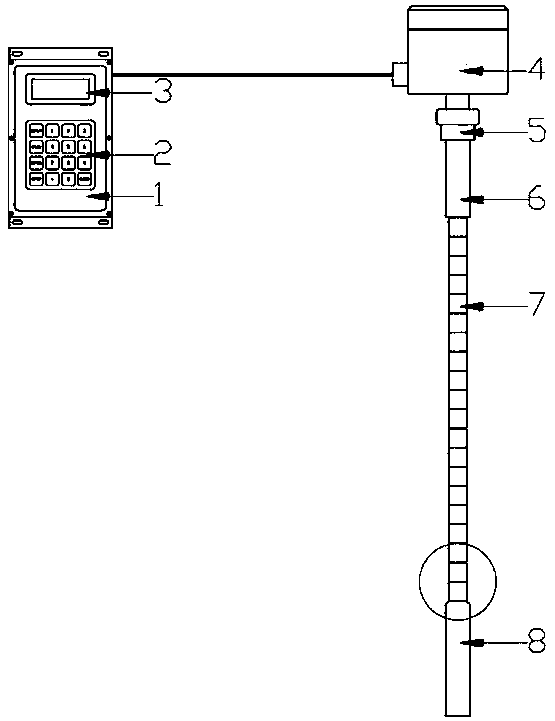

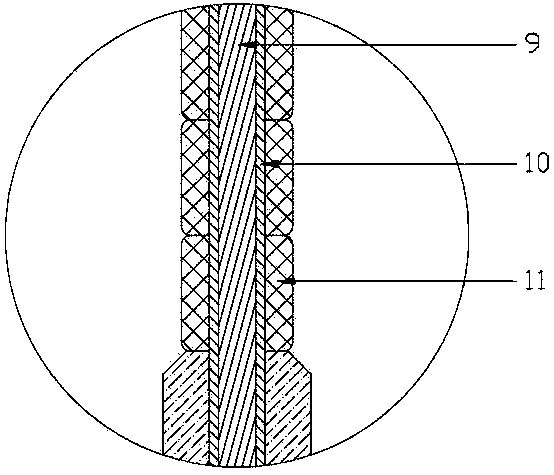

Method used

Image

Examples

Embodiment

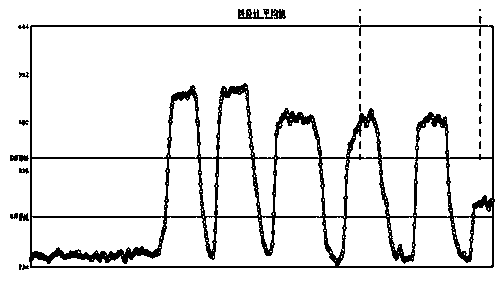

[0035] Such as image 3 The trend diagram shown in combination with the auxiliary time curve diagram can judge the suspension of the ash hopper and the damage of the valve. The operation mode after the transformation is mainly based on the material level signal control:

[0036] (1) Under normal circumstances, each conveying unit is automatically programmed to operate according to the set parameters. The process is to start the operation and the feed valve is opened (the conveying tank starts to load ash) --- the material level of the conveying tank reaches the set value or the set ash loading When the time is up---the feed valve is closed---the discharge valve is opened-the intake valve is opened (start conveying)-the pressure of the conveying pipeline drops to the set value---the intake valve is closed (a conveying cycle ends) - go to next loop.

[0037] (2) This program sets two parameter setting windows, which are the setting of the ash level height of the feed material a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com