High-hardness transparent microcrystal glass with crystal oriented array structure and preparation method of high-hardness transparent microcrystal glass

A technology of crystal orientation and glass-ceramics, which is applied in the field of glass materials, can solve the problems of high cost, limited improvement of the surface hardness of transparent glass-ceramics, and inability to achieve synergistic resistance to external force scratches, so as to promote nucleation and crystallization , good hardness and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

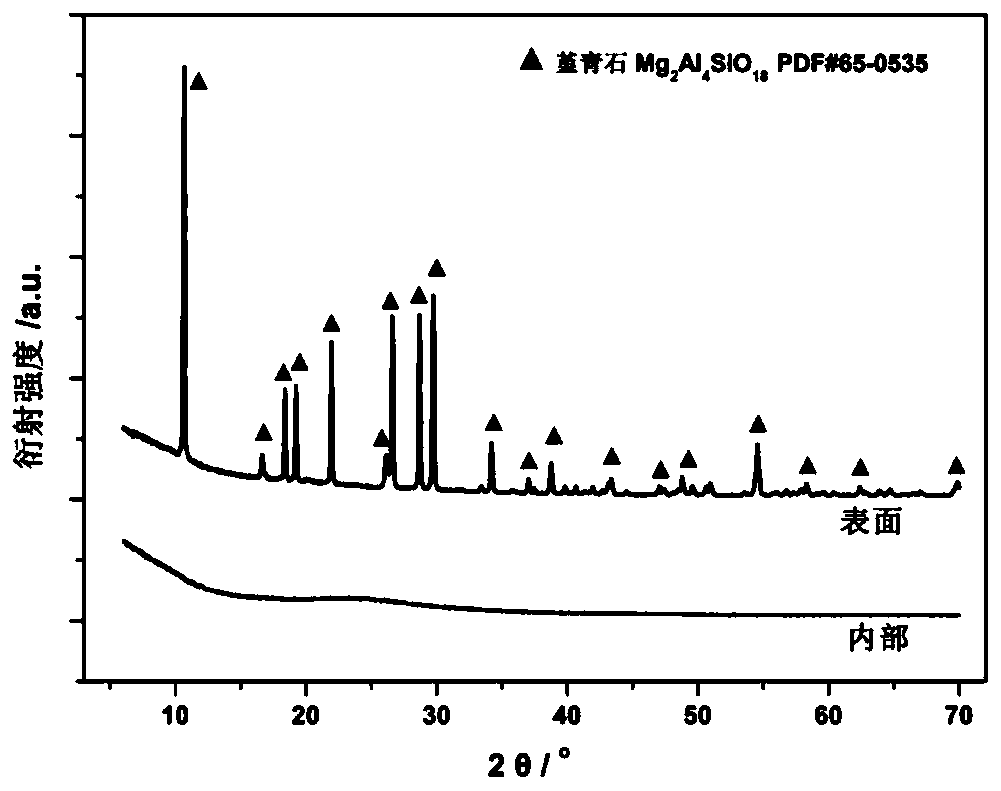

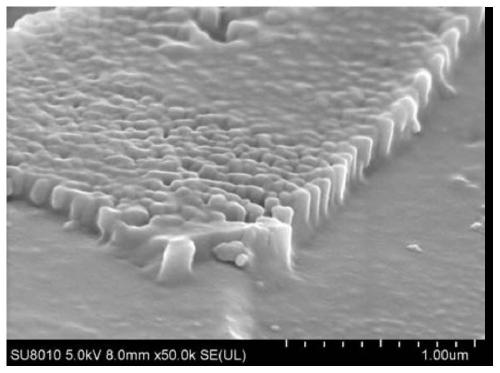

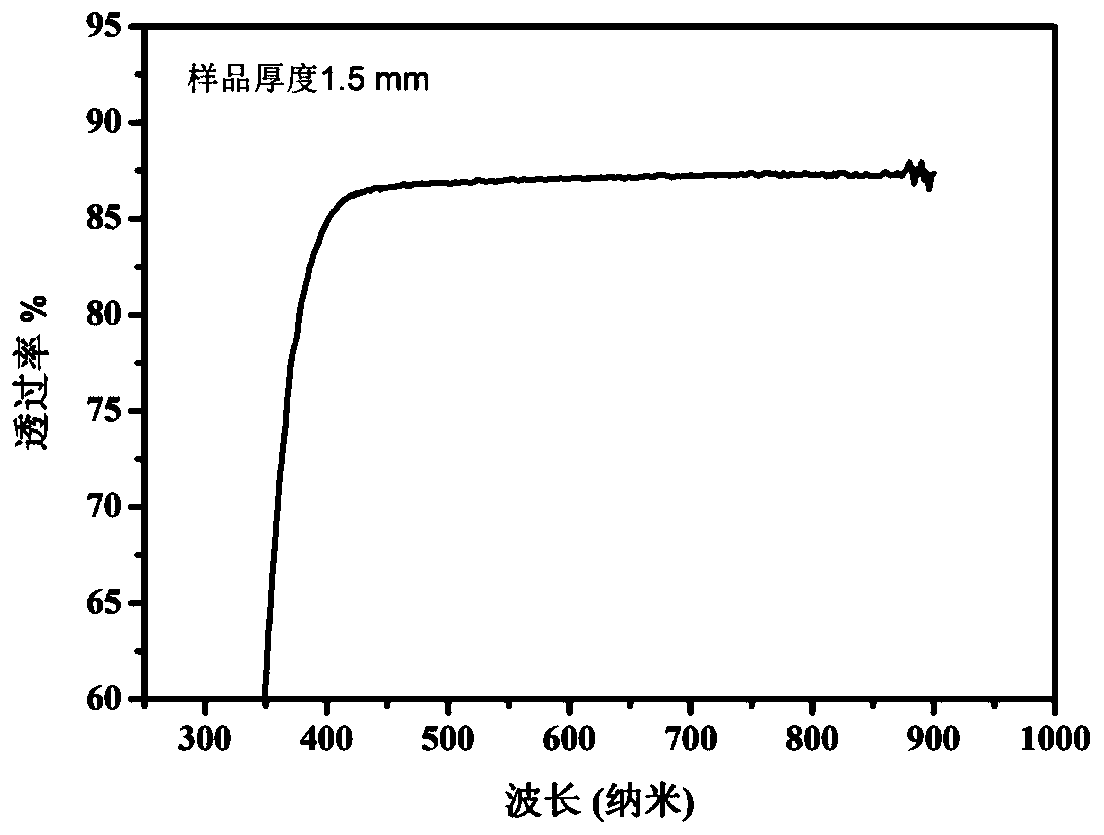

[0030] 1. In this embodiment, a kind of high-hardness transparent glass-ceramic with crystal orientation arrangement structure is made of MgO-B 2 o 3 -Al 2 o 3 -SiO 2 The basic glass of the system, and the cordierite crystal layer with a vertically aligned structure on its surface. Wherein, the base glass consists of 10 parts of MgO, B 2 o 3 5 parts, Al 2 o 3 31 parts, SiO 2 49 copies, GeO 2 1.5 parts, TiO 2 1 part, ZrO 2 1 copy, P 2 o 5 1.5 parts; the cordierite crystal layer is made of GeO by heat treatment 2 In situ growth of seed crystals induced on the base glass surface, GeO 2 The seed crystal consists of amorphous GeO 2 GeO made by mixing glass powder and water 2 The seed crystal suspension is coated on the surface of the base glass and introduced, according to the mass ratio of GeO 2 Glass powder: water=1:220.

[0031] 2. The preparation method of the high-hardness transparent glass-ceramic with crystal alignment structure in this embodiment, the step...

Embodiment 2

[0040] 1. In this embodiment, a kind of high-hardness transparent glass-ceramic with crystal orientation arrangement structure is made of MgO-B 2 o 3 -Al 2 o 3 -SiO 2 The basic glass of the system, and the cordierite crystal layer with a vertically aligned structure on its surface. Wherein, the base glass consists of 12 parts of MgO, B 2 o 3 7 copies, Al 2 o 3 28 parts, SiO 2 47 copies, GeO 2 3 parts, TiO 2 1 part, ZrO 2 1 part; the cordierite crystal layer is made of GeO by heat treatment 2 In situ growth of seed crystals induced on the base glass surface, GeO 2 The seed crystal consists of amorphous GeO 2 GeO made by mixing glass powder and water 2 The seed crystal suspension is coated on the surface of the base glass and introduced, according to the mass ratio of GeO 2 Glass powder: water=1:270.

[0041] 2. In this embodiment, a method for preparing a high-hardness transparent glass-ceramic having a crystal alignment structure, the steps are as follows:

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Surface microhardness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com