Method for synthesizing water-soluble cellulose acetate by one step

A cellulose acetate and water-soluble technology, which is applied in the field of one-step synthesis of water-soluble cellulose acetate, can solve the problems of uneven distribution of acetic acid substituents, high viscosity and high degree of substitution, and achieves improved solubility, low viscosity, and guaranteed cellulose. The effect of degree of aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Take 1.8 mL of valeryl chloride and slowly add it dropwise to 30 g of ionic liquid 1-ethyl-3-methylimidazole acetate, and take 1.00 g of cotton linters to invade the above solvent system. Under 70℃ oil bath conditions Magnetic stirring is used to obtain a transparent, viscous and completely dissolved cellulose solution. Under the condition of continuous magnetic stirring, the reaction is kept at 70°C for 12 hours. After the reaction, the system was poured into 200 ml of ethanol to terminate the reaction, followed by repeated washing and filtering with a large amount of ethanol until the ionic liquid and unreacted reagents were cleaned, and a pure cellulose product was obtained. The product was verified to be soluble in water.

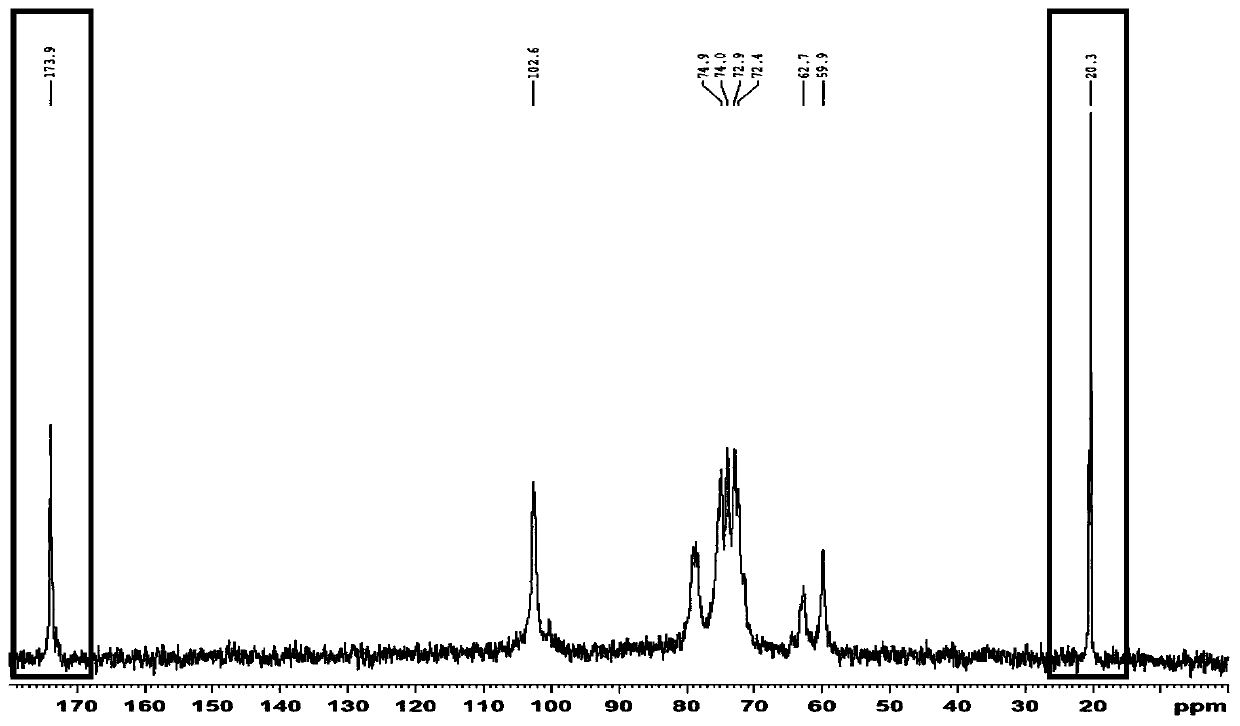

[0024] figure 1 It is shown that the absorption peak at 20.3 ppm indicates the presence of ethyl groups on the cellulose, and the absorption peak at 173.9 ppm indicates the presence of carbonyl groups. Combining the two absorption peaks, the cellulos...

Embodiment 2

[0029] Take 1.5 mL of valeryl chloride and slowly add dropwise to 30 g of ionic liquid 1-ethyl-3-methylimidazole acetate, and take 0.6 g of woody cellulose to invade the above solvent system, magnetically under the condition of 63℃ oil bath Stir to obtain a transparent, viscous, and completely dissolved cellulose solution. Under the condition of continuous magnetic stirring, keep the temperature for 9 hours. After the reaction, the system was poured into 200 ml of ethanol to terminate the reaction, followed by repeated washing and filtering with a large amount of ethanol until the ionic liquid and unreacted reagents were cleaned, and a pure cellulose acetate product was obtained. The product was verified to be soluble in water.

Embodiment 3

[0031] Take 3 mL of valeryl chloride and slowly add dropwise to 30 g of ionic liquid 1-ethyl-3-methylimidazole acetate, take 1.5 g of herbal cellulose into the above solvent system, and magnetically stir at 55°C in an oil bath. A transparent, viscous, and completely dissolved cellulose solution was obtained, and the reaction was maintained at 55°C for 6 hours under the condition of continuous magnetic stirring. After the reaction, the system was slowly poured into 200ml of ethanol to terminate the reaction, followed by repeated washing and filtration with a large amount of ethanol until the ionic liquid and unreacted reagents were cleaned, and a pure cellulose acetate product was obtained. water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com