Non-ionic reaction epoxy resin emulsifying agent and preparation method thereof

A non-ionic reaction type, epoxy resin technology, applied in the direction of epoxy resin coatings, coatings, anti-corrosion coatings, etc., can solve the problems of poor corrosion resistance of coating films, easy to be destroyed, poor emulsion stability, etc., to achieve a balance Strong resistance, improved corrosion resistance, high curing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

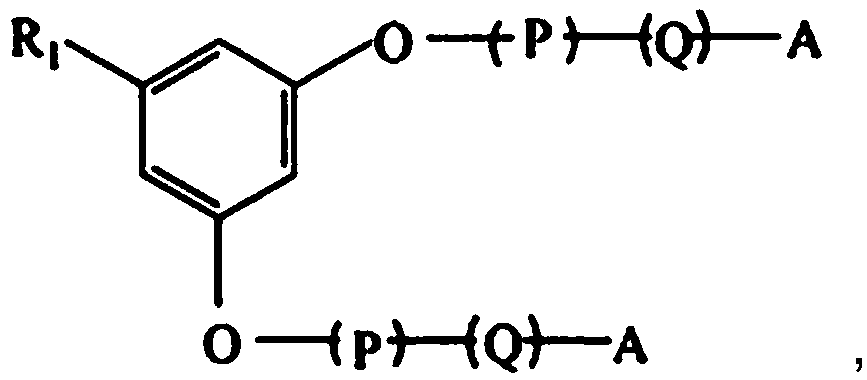

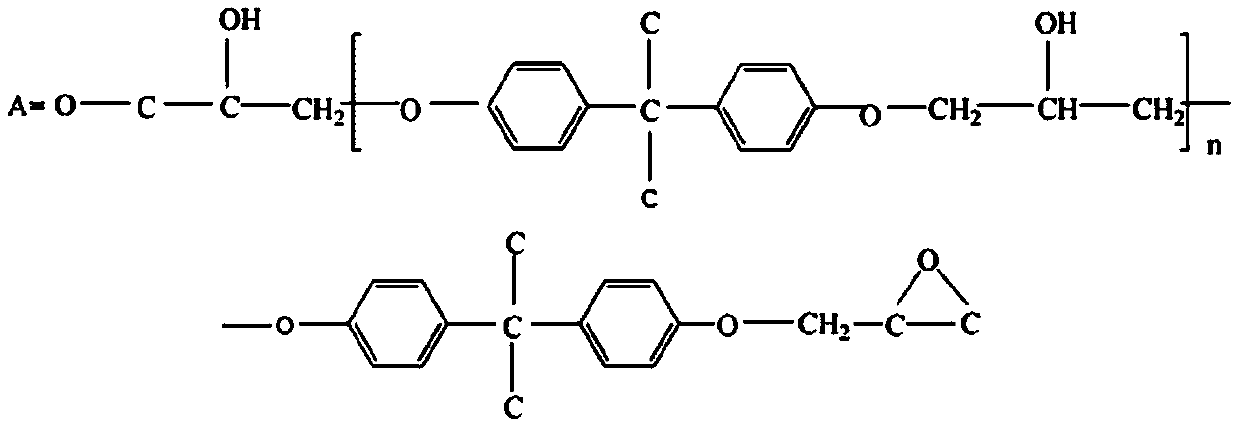

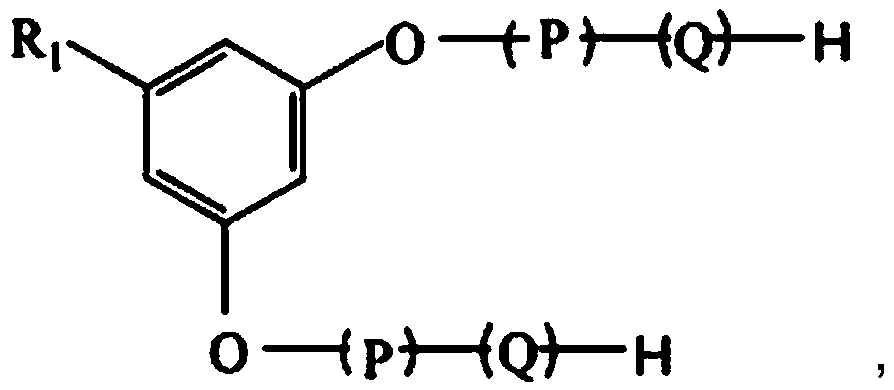

Method used

Image

Examples

Embodiment 1

[0041] Add 350g of cardiotonic polyether into a reactor with heating and stirring device, heat to 90℃ to melt into liquid, then add 2.5g of boron trifluoride-ether solution, stir well, then slowly add 150g of bisphenol A epoxy After mixing the resin, it is sealed and reacted at 90℃ for 3 hours. When the reaction is complete and the epoxy equivalent index reaches the theoretical value, 10g of sodium hydroxide aqueous solution with a mass concentration of 5% is added for neutralization, and the material is discharged to obtain a non-ionic reaction Type epoxy resin emulsifier.

Embodiment 2

[0043] Add 350g of cardiotonic phenol polyether into a reactor with heating and stirring device, heat to 90℃ to melt into liquid, then add 2.5g of boron trifluoride-ether solution, stir well, and then slowly add 170g of bisphenol A epoxy After mixing the resin, it is sealed and reacted at 90℃ for 3 hours. When the reaction is complete and the epoxy equivalent index reaches the theoretical value, 10g of sodium hydroxide aqueous solution with a mass concentration of 5% is added for neutralization, and the material is discharged to obtain a non-ionic reaction Type epoxy resin emulsifier.

Embodiment 3

[0045] Add 350g of cardiotonic polyether into a reactor with heating and stirring device, heat to 90℃ to melt into liquid, add 5g of potassium persulfate solution, stir well, then slowly add 170g of bisphenol A epoxy resin, and stir well. , Sealed reaction at 90 ℃ for 3 hours, when the reaction is complete, the epoxy equivalent index reaches the theoretical value, add 10g of sodium hydroxide aqueous solution with a mass concentration of 5% for neutralization, and discharge the non-ionic reactive epoxy resin emulsification Agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com