Construction method and application of high-yield L-threonine gene engineering bacterium

A technology of genetically engineered bacteria and threonine, which is applied in the field of genetic engineering and microbial fermentation, can solve the problems of the theoretical conversion rate gap and other problems, and achieve the effects of saving fermentation costs, accelerating the growth of strains, and improving the conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

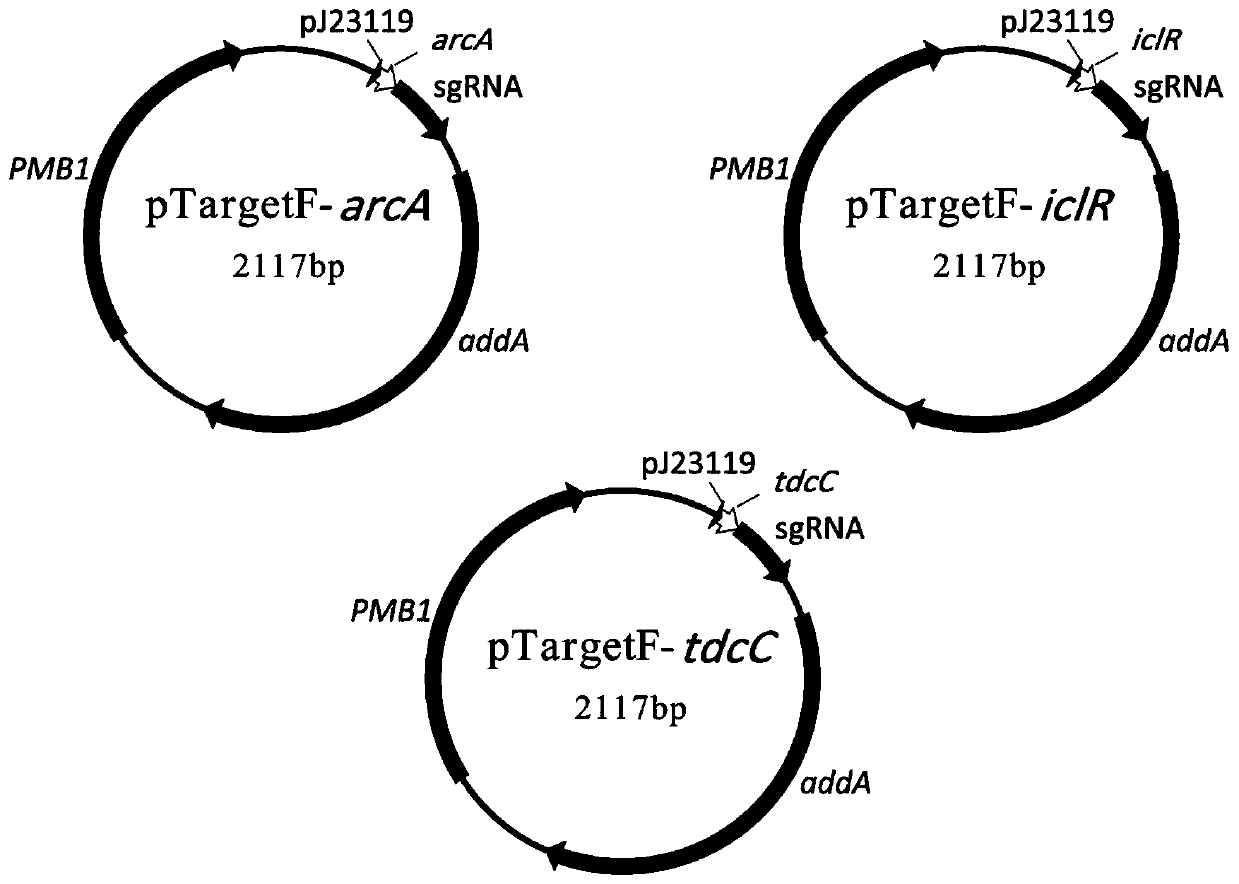

[0028] Example 1: Construction of pTargetF-arcA, pTargetF-iclR, pTargetF-tdcC knockout plasmids

[0029] Using pTargetF as a template, three pairs of primers, sgRNA-arcA-F and T-sgRNA-R, sgRNA-iclR-F and T-sgRNA-R, sgRNA-tdcC-F and T-sgRNA-R, were used for PCR amplification respectively. The PCR products were detected by gel electrophoresis, and the size of the obtained products met the expected size. The purified linear pTargetF-arcA, pTargetF-iclR, and pTargetF-tdcC fragments were obtained using a gel recovery kit, and then 200ng of the above fragments were respectively taken and added to 0.5ul DpnⅠ, 1ul DpnⅠbuffer, 6ul ddH 2 O Place in a 37°C water bath to digest the template plasmid pTargeTF, then add 2ul PNK phosphorylase and 2ul buffer, 6ul ddH 2 O was placed in a water bath at 37°C for phosphorylation, then placed in a water bath at 65°C for 10 minutes to inactivate the enzyme, and finally T4 DNA ligase was added and placed at 22°C for 4 hours. Transform the above lig...

Embodiment 2

[0034] Embodiment 2: construction of arcAUD, iclRUD, tdccUD knockout fragment

[0035]According to the gene sequences of arcA (SEQ ID NO.1), iclR (SEQ ID NO.2), and tdcC (SEQ ID NO.3) reported by Genebank, fragments of about 500 bp in size from the upstream and downstream of the gene were selected as the upstream and downstream homology of the knockout gene Arm, where arcAU, arcAD are used for knockout of arcA gene; iclRU, iclRD are used for knockout of iclR gene; tdccU, tdccD are used for knockout of tdcc gene. The following 6 pairs of primers were designed and used to clone arcAU, arcAD, iclRU, iclRD, tdccU, tdccD sequences respectively:

[0036] arcAf1:ACGCATATTGCCACTTCTTCT

[0037] arcAr1: TTACGAATACGGCGGATCTGCGTGTTACCAACTCGTC

[0038] arcAf2: GACGAGTTGGTAACACGCAGATCCGCCGTATTCGTAA

[0039] arcAr2: GCAAGCGGTATTGAAAGG

[0040] iclRf1:ATCGCAATGGTCGTGGAG

[0041] iclRr1: GACACCCTTATTCTATTGCCACGTTTATGCCAGTATGGTTTG

[0042] iclRf2: CAAACCATACTGGCATAAACGTGGCAATAGAATAAGGGTGT...

Embodiment 3

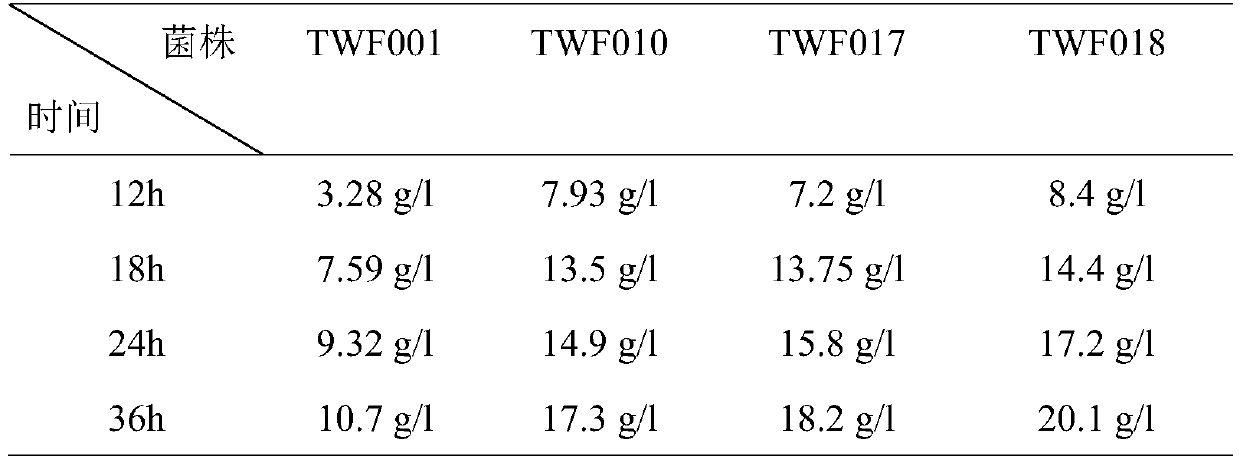

[0049] Embodiment 3: construction of arcA, iclR, tdcC deletion strain

[0050] Using Escherichia coli TWF001 (published in the paper "Increasing L-threonine production in Escherichia coli by engineering the glyoxylate shunt and the l-threonine biosynthesis pathway" in 2018) as the starting strain, electroporation knockout plasmid pTargetF-arcA, and knockout Insert the fragment arcAUD into TWF001 to construct the deletion strain TWF001 to delete arcA. The specific operation process is as follows:

[0051] (1) Extract the plasmid pTargetF-arcA from Escherichia coli JM109, and wash it with pH 8.0 water for later use.

[0052] (2) Electroporation of the knockout plasmid pTargetF-arcA and the knockout fragment arcAUD to Escherichia coli TWF001 containing pCas, the bacterial solution was spread on an LB plate containing kanamycin and spectinomycin for cultivation, and the correct transformant was obtained by screening.

[0053] (3) The transformants of (2) were induced by IPTG and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com