Four fluorescent powder LED proportion and dispensing quantity recommendation method based on least square method

A technique of least square method and recommended method, which is applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of time-consuming and labor-consuming, long trial production cycle, waste of cost, etc., to shorten the sample and improve Production efficiency and yield, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

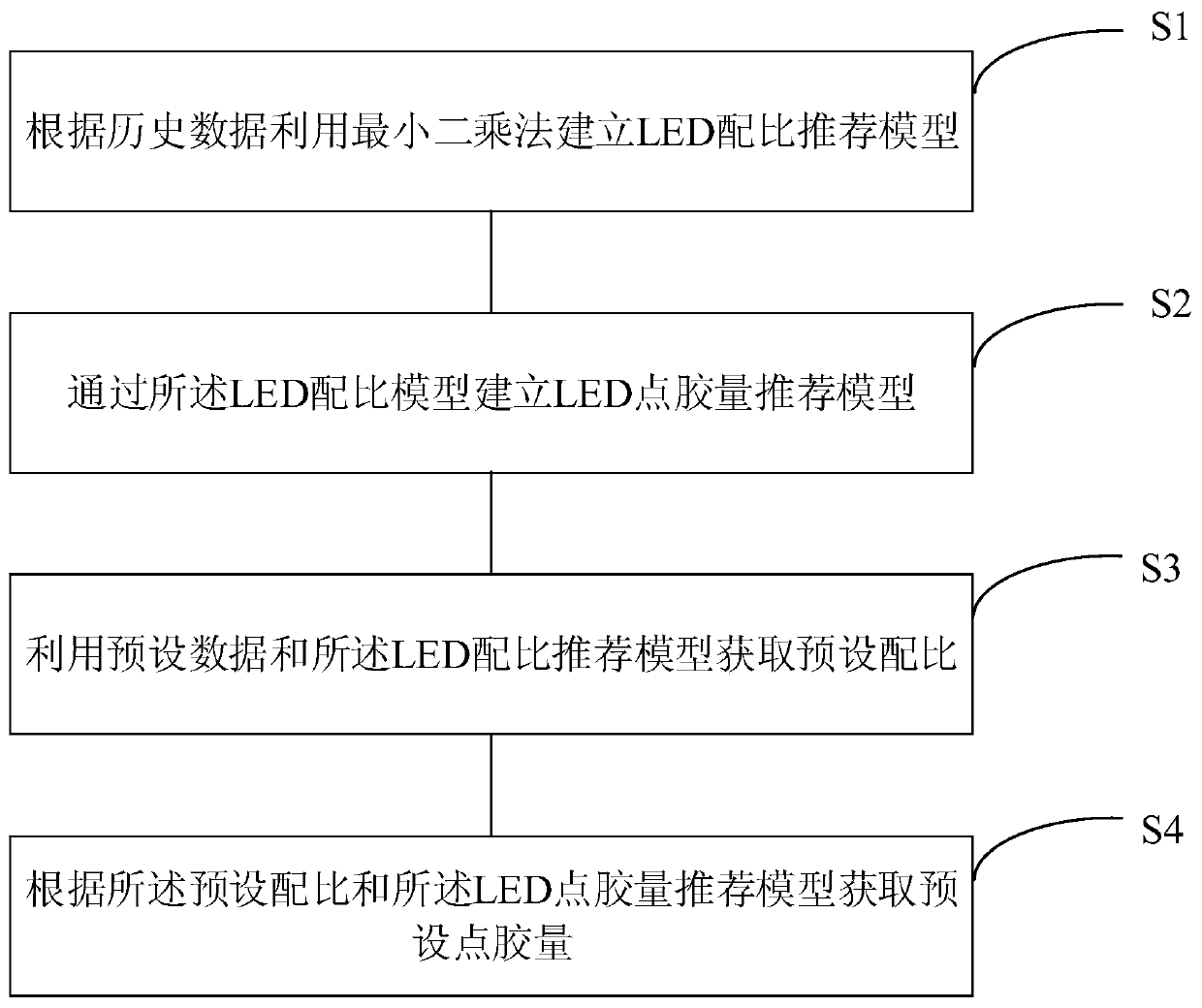

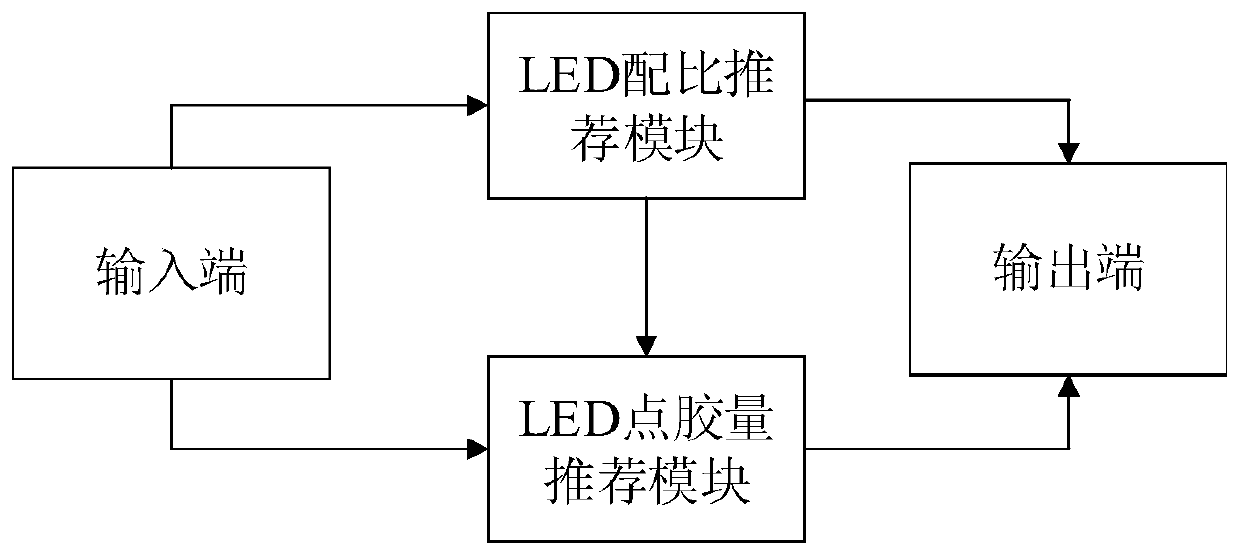

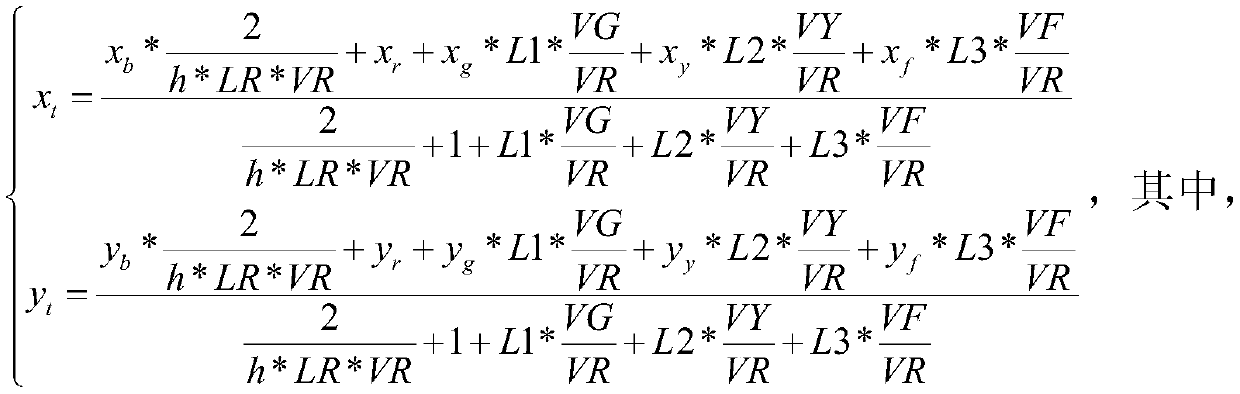

[0044] See figure 1 and figure 2 , figure 1 A structural schematic diagram of a four-phosphor LED ratio and dispensing amount recommendation method based on the least squares method provided by the embodiment of the present invention; figure 2 A schematic structural diagram of an equipment for recommending ratios and dispensing amounts of four phosphor LEDs based on the least squares method provided by an embodiment of the present invention. The packaging method of white light LED can be made into the phosphor required by the product through red phosphor, green phosphor, yellow phosphor, and patented yellow phosphor, and then through the blue chip to form white light.

[0045] Such as figure 1 As shown, a method for recommending the ratio of two phosphor LEDs and the amount of glue dispensed based on the least squares method, including:

[0046] S1. Based on the historical data, use the least square method to establish the LED ratio recommendation model;

[0047] S2. Es...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com