Switch reluctance machine sensor redundancy system and automatic switching method

A technology of switched reluctance motor and redundant system, which is applied in the direction of electrical components, electromechanical devices, emergency protection circuit devices, etc., which can solve the problems of motor control phase current imbalance, loud noise, damage, etc., and improve trouble-free operation time, strong anti-interference ability and high protection level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

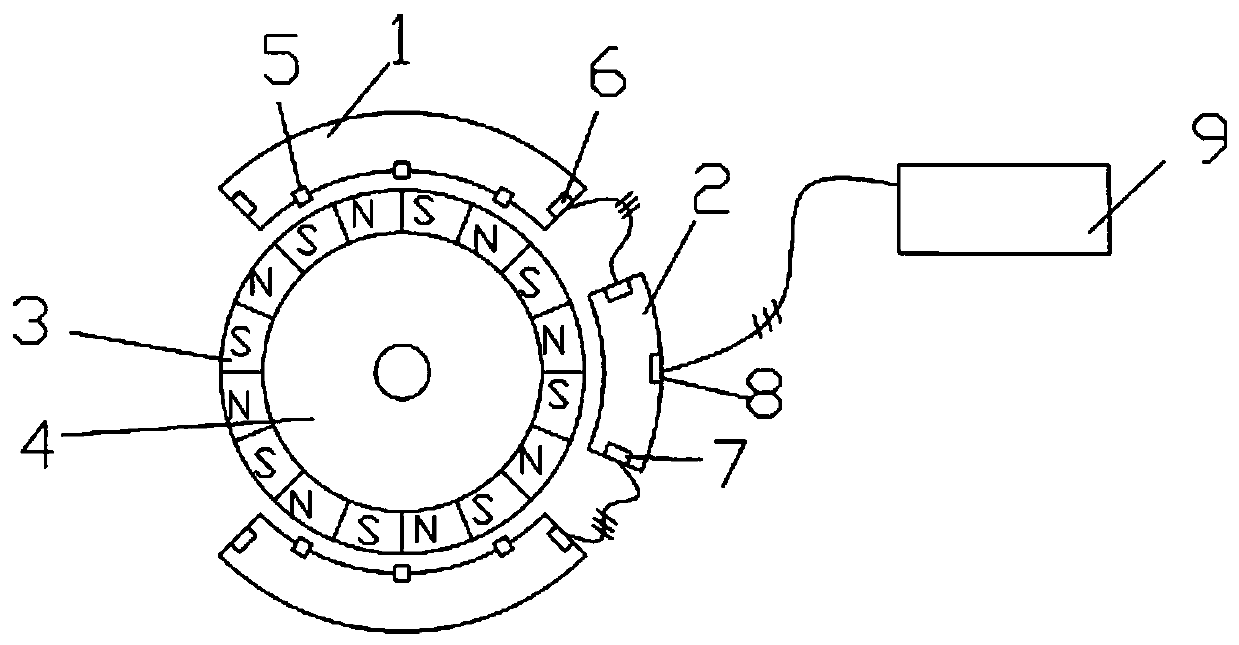

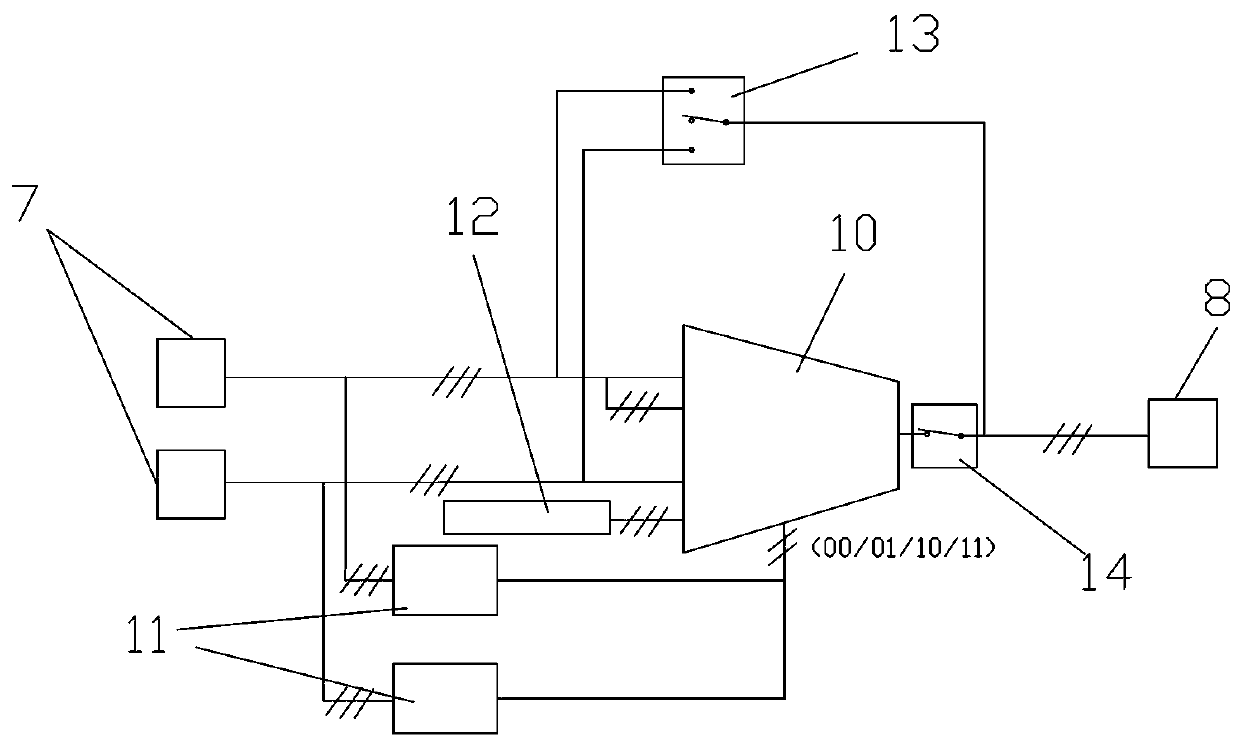

[0039] Embodiment 1: as figure 1 and figure 2 as shown,

[0040] The system consists of two sensor boards 1 , an interface circuit board 2 , a magnetic ring 3 , and a magnetic ring support 4 . Three Hall sensors 5 and their related signal processing circuits are arranged on the sensor board 1 according to the phases of the motor, and the signal output interface I6 is arranged on the board edge of the sensor board 1 . The sensor board 1 is connected to the interface circuit board 2 through the signal line. The interface circuit board 2 is equipped with two signal input interfaces Ⅰ7 and one signal output interface Ⅱ8. It is equipped with a fault automatic switching circuit, which can realize the failure of one sensor board 1. , automatically switches to the spare sensor board 1. The magnetic ring 3 is radially magnetized according to the motor rotor pole number 16, the sensor board 1 and the interface circuit board 2 are fixed on the motor end cover; the magnetic ring 3 is ...

Embodiment 2

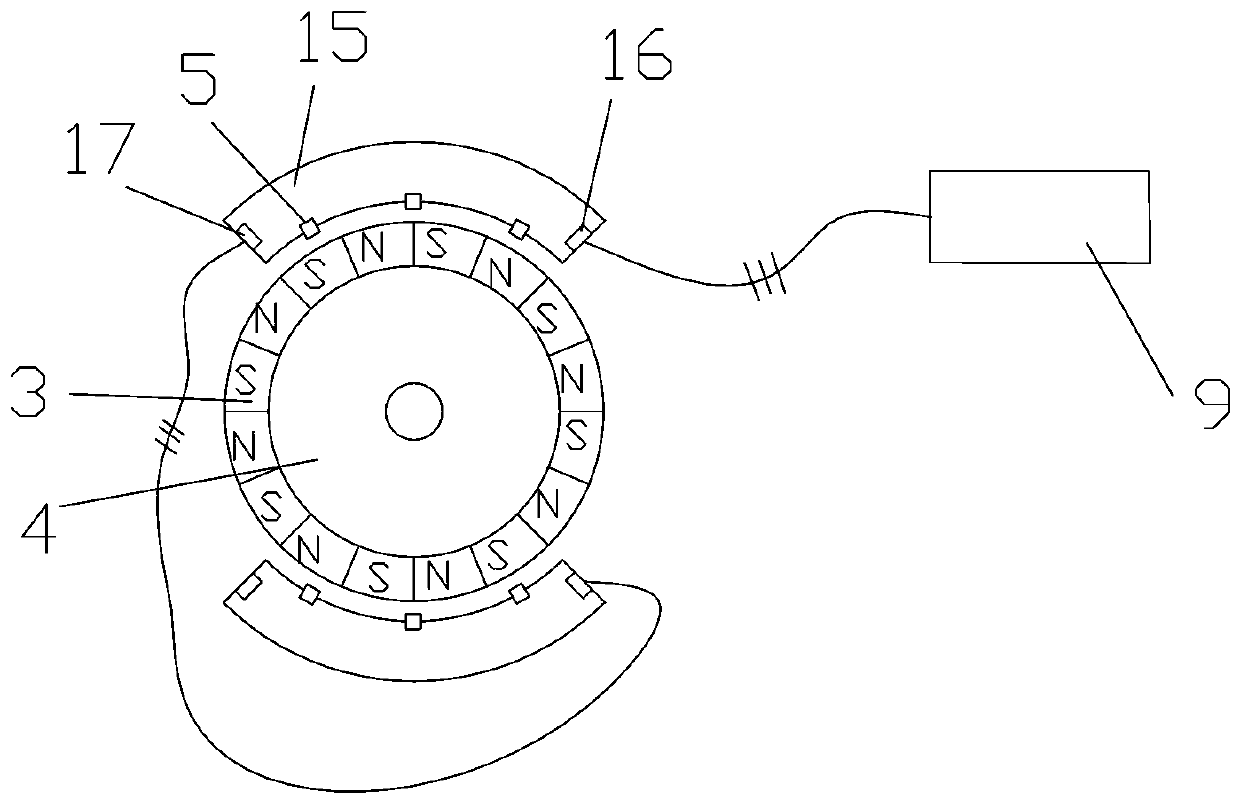

[0046] Embodiment 2: as image 3 and Figure 4 as shown,

[0047] The sensor board 1 and the interface circuit board 2 are integrated into a sensor integration board 15 , so that the signal output interface III 16 on the sensor integration board 15 is connected to the motor control board 9 .

[0048] The system consists of two sensor integrated boards 15 , a magnetic ring 3 , and a magnetic ring support 4 . Three Hall sensors 5 and their related signal processing circuits and switching circuits are arranged on the sensor integrated board 15 according to the phase number of the motor, and the signal output interface III16 and the signal input interface II17 are arranged on the edge of the board. The sensor integrated board 15 is provided with a fault automatic switching circuit, which can automatically switch to the standby sensor board 1 in case of failure of the present sensor board 1 . The magnetic ring 3 is radially magnetized according to the motor rotor pole number 16,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com