Thin film deposition method and device based on inert gas/oxygen plasma

A thin film deposition device and oxygen plasma technology, applied in the application field of plasma technology, can solve the problems of thin film defects and small thin film area, and achieve the effects of compact and compact structure, increase deposition area, and ensure strength and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

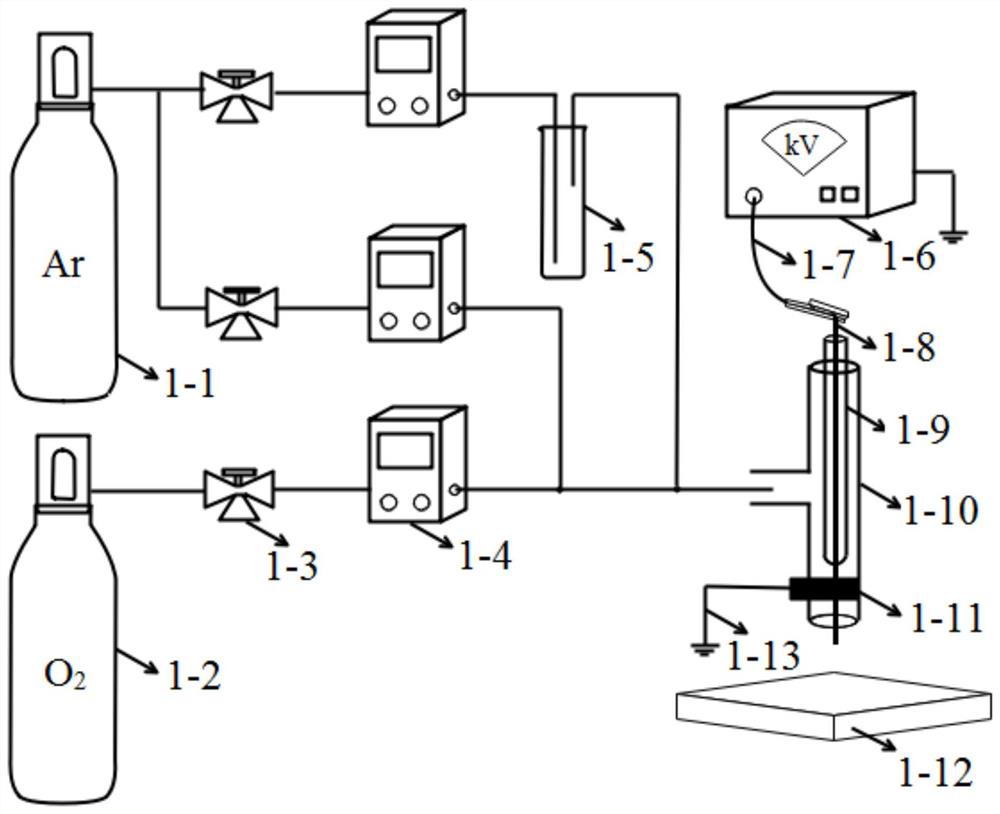

[0048] This embodiment provides a thin film deposition device based on inert gas / oxygen plasma, such as figure 1 As shown, it includes an inert gas supply device and an oxygen supply device, for example, the inert gas supply device can be an argon gas cylinder 1-1, and the oxygen supply device can be an oxygen cylinder 1-2, and also includes,

[0049] A precursor liquid storage device, the air inlet of which is in communication with the inert gas supply device, so that the precursor is taken out of the precursor liquid storage device by an inert gas, specifically, the precursor liquid storage device is equipped with a precursor Body bubbler bottles 1-5;

[0050] A plasma processing device comprising an inner tube, an outer tube sheathed outside the inner tube with openings at both ends, and a high-voltage electrode 1-8 placed in the inner tube, openings are provided on the side wall of the outer tube, The oxygen supply device communicates with the opening through a pipeline, ...

Embodiment 2

[0068] This embodiment provides a thin film deposition method based on inert gas / oxygen plasma, comprising the following steps:

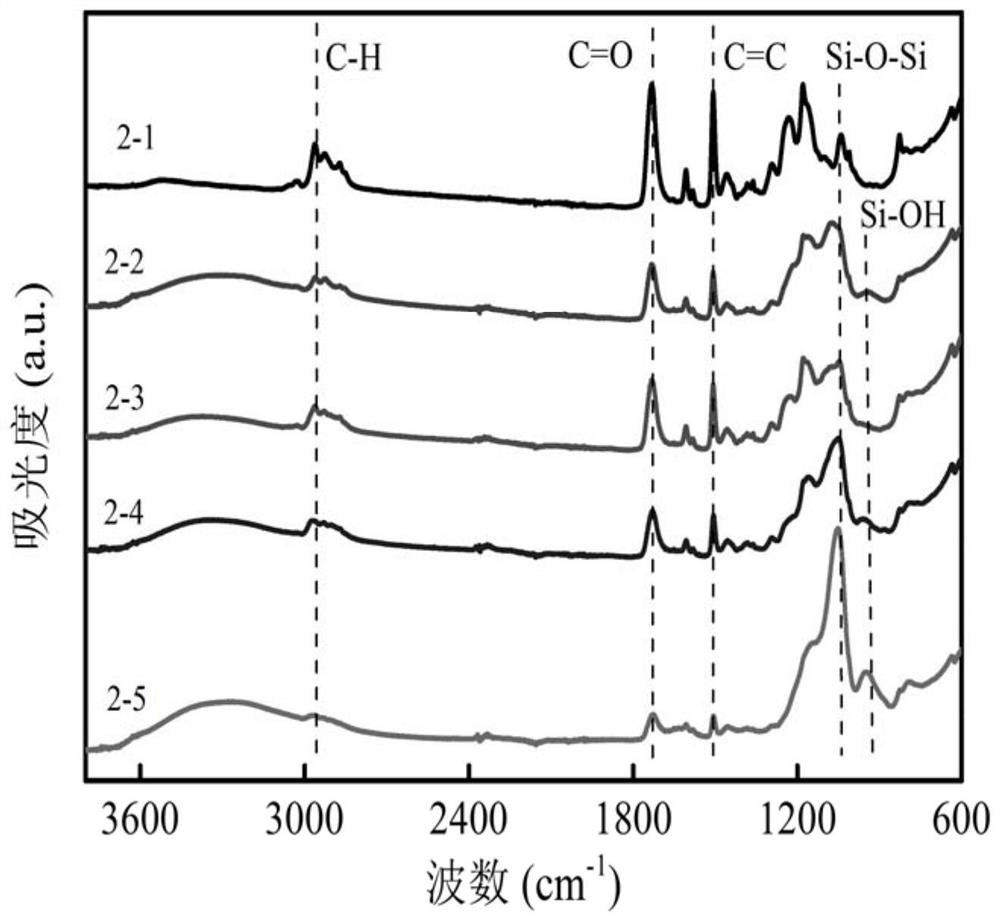

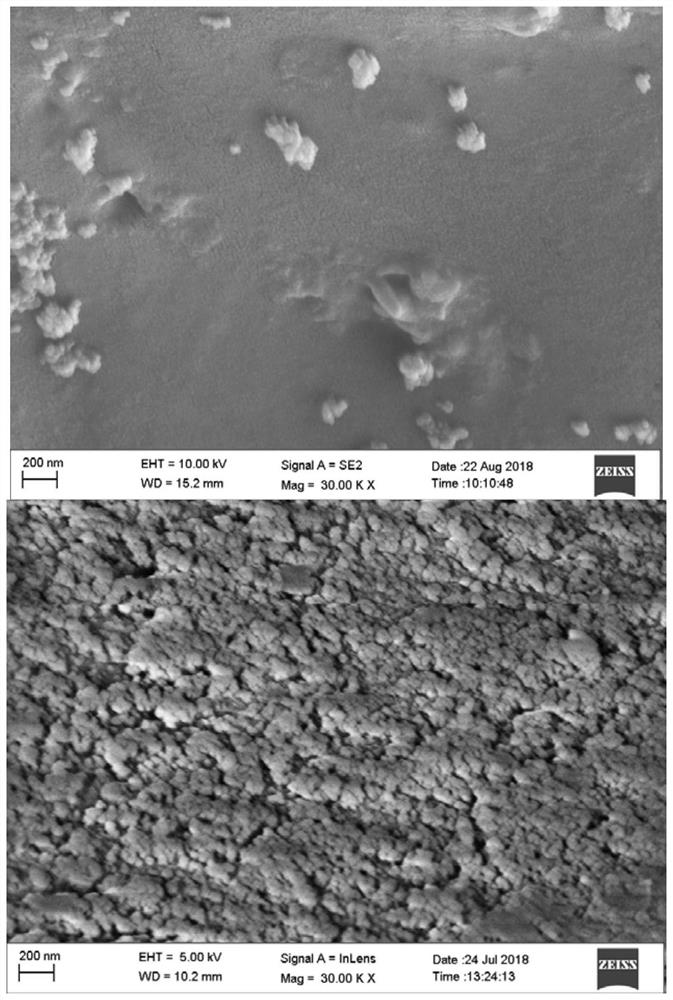

[0069] Select the epoxy resin doped with aluminum oxide (Al 2 o 3 -ER) as the substrate material, after wiping the sample with a dust-free cloth and absolute ethanol, put it into an ultrasonic cleaner filled with deionized water for cleaning, the cleaning temperature is 70°C, and the cleaning time is 20min; then put it into a vacuum Dry in a drying oven with an air pressure of 3kPa, a drying temperature of 70°C, and a drying time of 10 hours; after drying, the substrate material is placed on a heating platform, the substrate material is controlled at 100°C, and the precursor is tetraethyl orthosilicate (TEOS ), heated in an oil bath at 60°C, the flow rate of the argon flow into TEOS was 300 sccm, the flow rate of the other argon flow was 3 slm, the flow rate of oxygen was set to 50 sccm respectively, the high-frequency high-voltage power supply app...

Embodiment 3

[0078] This embodiment provides a thin film deposition method based on inert gas / oxygen plasma, comprising the following steps:

[0079] Select polystyrene with a size of 50×50×2mm as the substrate material. After wiping the sample with a dust-free cloth and absolute ethanol, put it into an ultrasonic cleaner filled with deionized water for cleaning. The cleaning temperature is 65°C and the cleaning time is Then put it into a vacuum drying oven for drying, the air pressure is 3kPa, the drying temperature is 75°C, and the drying time is 9h; after drying, place the substrate material on the heating platform, control the substrate material at 70°C, and TiCl 4 , heated in an oil bath at 65°C, and passed through TiCl 4 The argon flow rate of the first channel is 50sccm, the other argon flow rate is 3slm, the oxygen flow rate is set to 15sccm respectively, the applied voltage of high-frequency high-voltage power supply is 12kV, and the frequency is 15kHz. After plasma treatment, Ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com