TiAl-based abrasion-resistant laser cladding coating powder and preparation method thereof

A laser cladding and coating technology, applied in the field of surface modification of laser cladding metal materials, can solve the problems of low bonding strength, poor wettability, and many coating cracks, achieve high hardness, good wear resistance, reduce Splash and Volatile Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

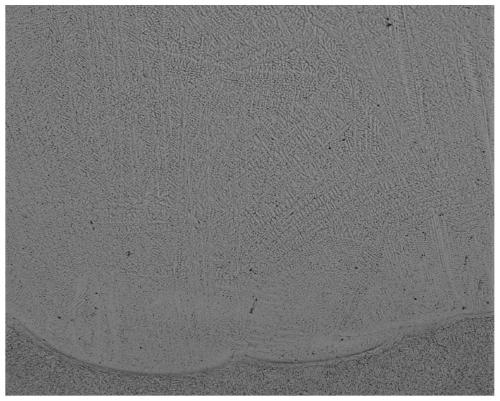

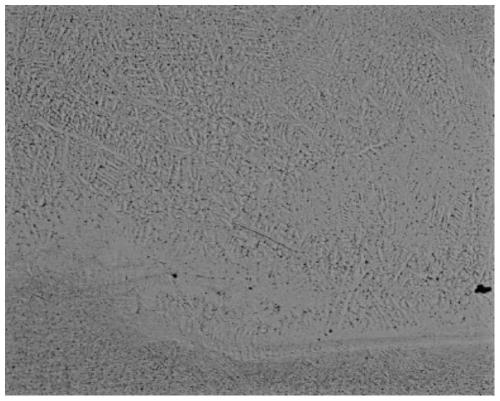

Image

Examples

Embodiment 1

[0035] The TiAl-based wear-resistant laser cladding coating powder is composed of the following mass percentage components: TiAl master alloy powder 86.5%, Si powder 10%, HfO 2 Powder 1%, La 2 o 3 Powder 1%, B powder 1%, CeO 2 Powder 0.5%.

[0036] The TiAl master alloy powder, Si powder, HfO 2 Powder, La 2 o 3 powder, B powder and CeO 2 The powder purity is above 99.5%, and the average particle size is 150 mesh. The above components are commercially available products.

[0037] The preparation method of the TiAl-based wear-resistant laser cladding coating powder, the steps include:

[0038] Step 1. Polish the metal substrate with sandpaper until the surface of the substrate is smooth, clean it with alcohol-acetone solution, and dry it for later use; the metal substrate is a titanium alloy (TC4 titanium alloy), and its chemical composition is shown in Table 1; polished and cleaned Specific steps: use 200# sandpaper on the surface of the metal substrate to polish the o...

Embodiment 2

[0046] The TiAl-based wear-resistant laser cladding coating powder is composed of the following mass percentage components: TiAl master alloy powder 60.5%, Si powder 20%, HfO 2 Powder 10%, La 2 o 3 Powder 5%, B powder 3%, CeO 2 Powder 1.5%.

[0047] The TiAl master alloy powder, Si powder, HfO 2 Powder, La 2 o 3 powder, B powder and CeO 2 The powder purity is above 99.5%, and the average particle size is 100 mesh. The above components are commercially available products.

[0048] The preparation method of the TiAl-based wear-resistant laser cladding coating powder, the steps include:

[0049] Step 1. Polish the metal substrate with sandpaper until the surface of the substrate is smooth, clean it with alcohol-acetone solution, and dry it for later use; the metal substrate is a titanium alloy (TC4 titanium alloy), and its chemical composition is shown in Table 1; polished and cleaned Specific steps: use 200# sandpaper on the surface of the metal substrate to polish the ...

Embodiment 3

[0055] The TiAl-based wear-resistant laser cladding coating powder is composed of the following mass percentage components: TiAl master alloy powder 73%, Si powder 15%, HfO 2 Powder 5%, La 2 o 3 Powder 4%, B powder 2%, CeO 2 Powder 1%.

[0056] The TiAl master alloy powder, Si powder, HfO 2 Powder, La 2 o 3 powder, B powder and CeO 2 The powder purity is above 99.5%, and the average particle size is 200 mesh. The above components are commercially available products.

[0057] The preparation method of the TiAl-based wear-resistant laser cladding coating powder, the steps include:

[0058] Step 1. Polish the metal substrate with sandpaper until the surface of the substrate is smooth, clean it with alcohol-acetone solution, and dry it for later use; the metal substrate is a titanium alloy (TC4 titanium alloy), and its chemical composition is shown in Table 1; polished and cleaned Specific steps: use 200# sandpaper on the surface of the metal substrate to polish the oxide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com