Fracturing method for increasing full-scale crack supporting volume of deep shale gas

A shale gas, full-scale technology, applied in the field of shale fracturing, can solve problems such as unsatisfactory production stability, production decline, insufficient support volume, etc., and achieve the effect of improving support efficiency and support volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

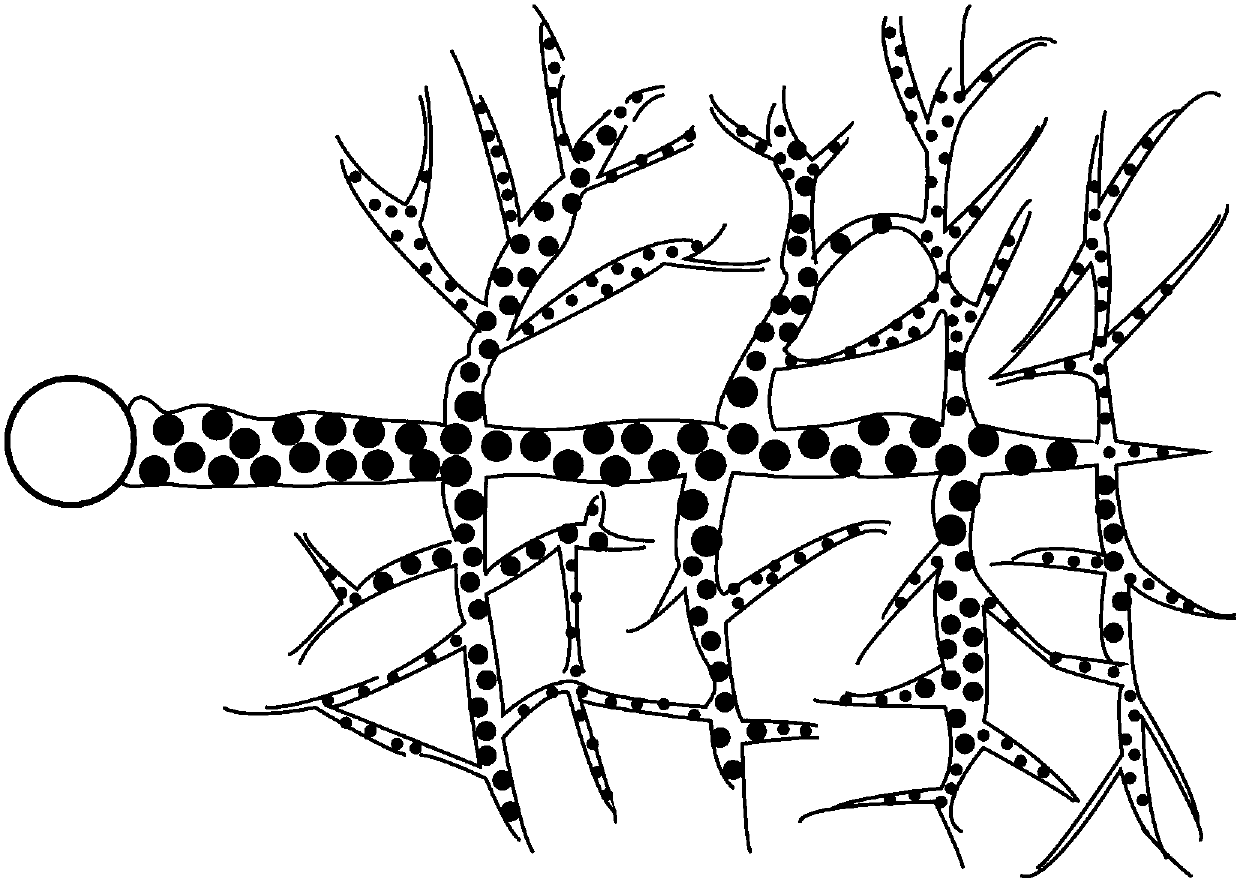

Image

Examples

Embodiment

[0062] A certain well has a vertical depth of 4417.43m, a measured depth of 5700m, and a horizontal section length of 1034m. Carry out fracturing design according to the contents of the present invention, the steps and results are as follows: 1. Optimizing the fracture parameters and construction parameters according to the geology and physical properties: the designed fracturing section spacing is 75-90m, the cluster spacing is 25-30m; the number of perforation clusters is 2 -3 clusters, a total of 64 holes; circumferential perforation, phase 60°; under normal circumstances, the construction scale is 1650 cubic meters of fluid (1070 cubic meters of smooth water + 380 cubic meters of low-viscosity fluid + 200 cubic meters of medium viscose fluid), 65 cubic meters of sand . ②According to the core and underground fluid of the pilot well, select the appropriate acidic slick water, acidic surface cross-linking acid formula system and formula system with different viscosity: the li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com