Oil inlet and outlet opening and closing structure for common-rail high-pressure oil pump

A technology of high-pressure oil pump and opening and closing structure, which is applied in the direction of fuel injection pump, engine components, machines/engines, etc., and can solve the problems of high machining accuracy requirements for split assembly structures, difficulty in ensuring stable sealing accuracy, and unfixed actual sealing surfaces, etc. , to achieve reliable sealing performance, ensure processing accuracy, and improve stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

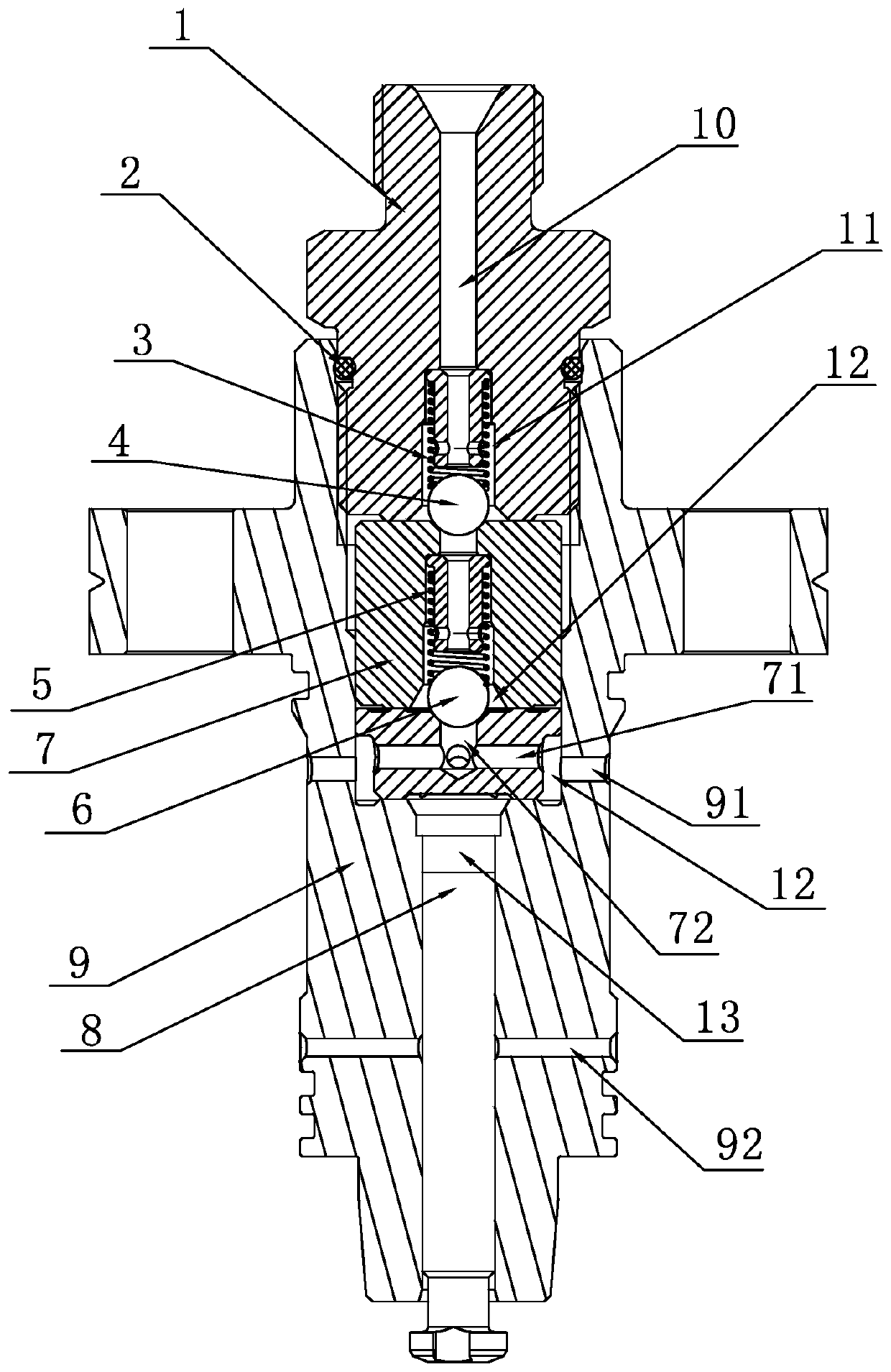

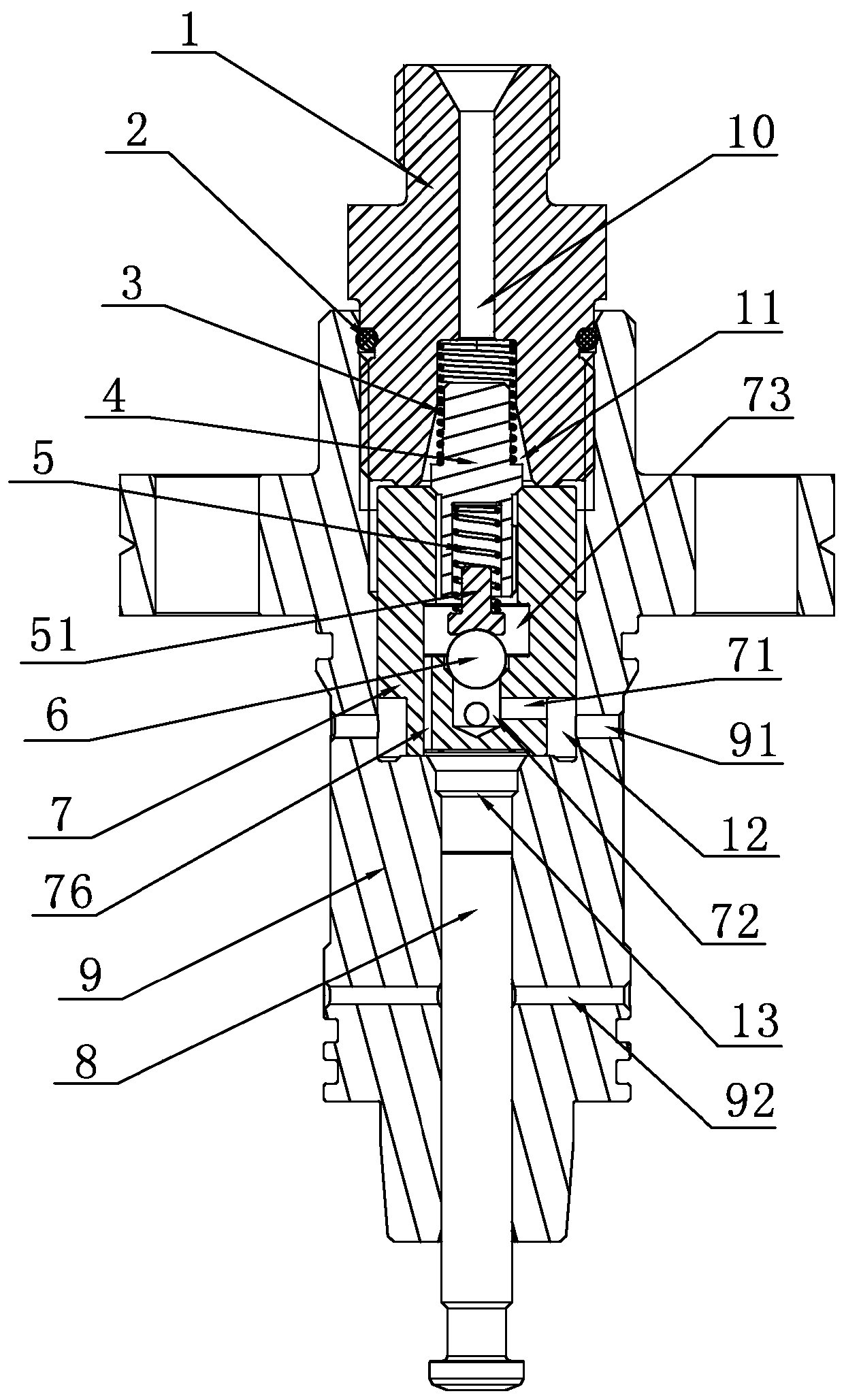

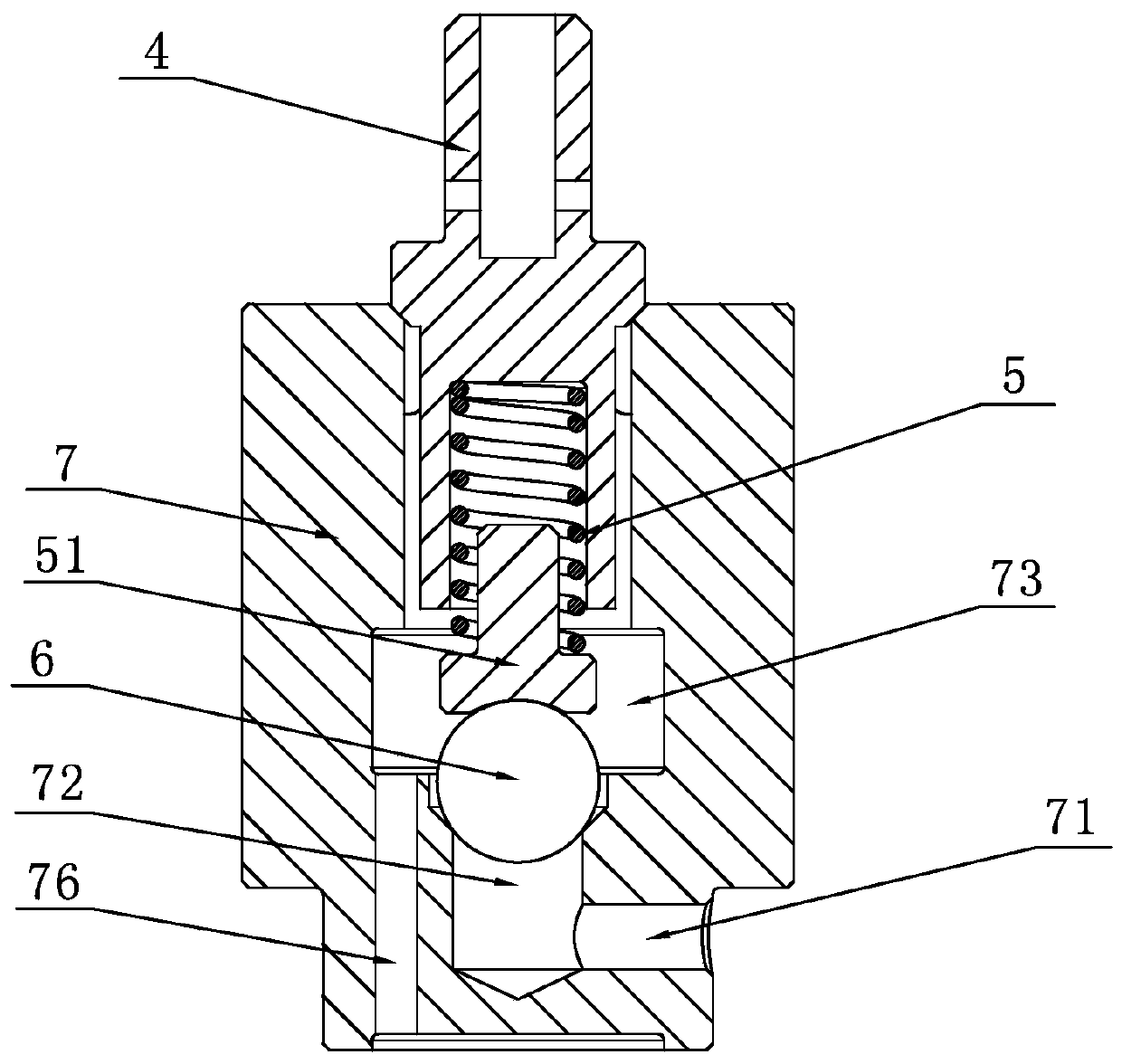

[0026] Embodiment 1: a kind of common rail high-pressure oil pump adopting the present invention, such as Figure 2-Figure 6 As shown, it includes an oil pipe joint 1, a sealing ring 2, an upper spring 3, an upper valve core 4, a lower spring 5, a steel ball 6, a valve seat 7, a plunger 8 and a valve body 9, and it is characterized in that: the upper valve core 4. It is composed of an upper cylinder 41, a sealing cone 42, a guide column 43 and a spring seat hole 44. The sealing cone 42 is arranged between the upper cylinder 41 and the guide column 43, and a sealing cone surface is provided on the sealing cone 42. 45. An axial oil inlet groove 46 is provided on the guide post 43, and the spring seat hole 44 is set at the center of the guide post 43. The diameter of the spring seat hole 44 is equivalent to the outer diameter of the lower spring 5, and the upper cylinder 41 is set on the upper In the inner hole of the spring 3, a central oil outlet hole 47 is provided in the cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com