Self-priming pump mechanical sealing part under positive and negative pressure working condition

A mechanical seal, positive and negative pressure technology, applied in the direction of mechanical equipment, pumps, drive pumps, etc., can solve the problems of high-temperature pump sealing, high price, low strength, etc., to save costs and equipment, improve stress conditions, Safe and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

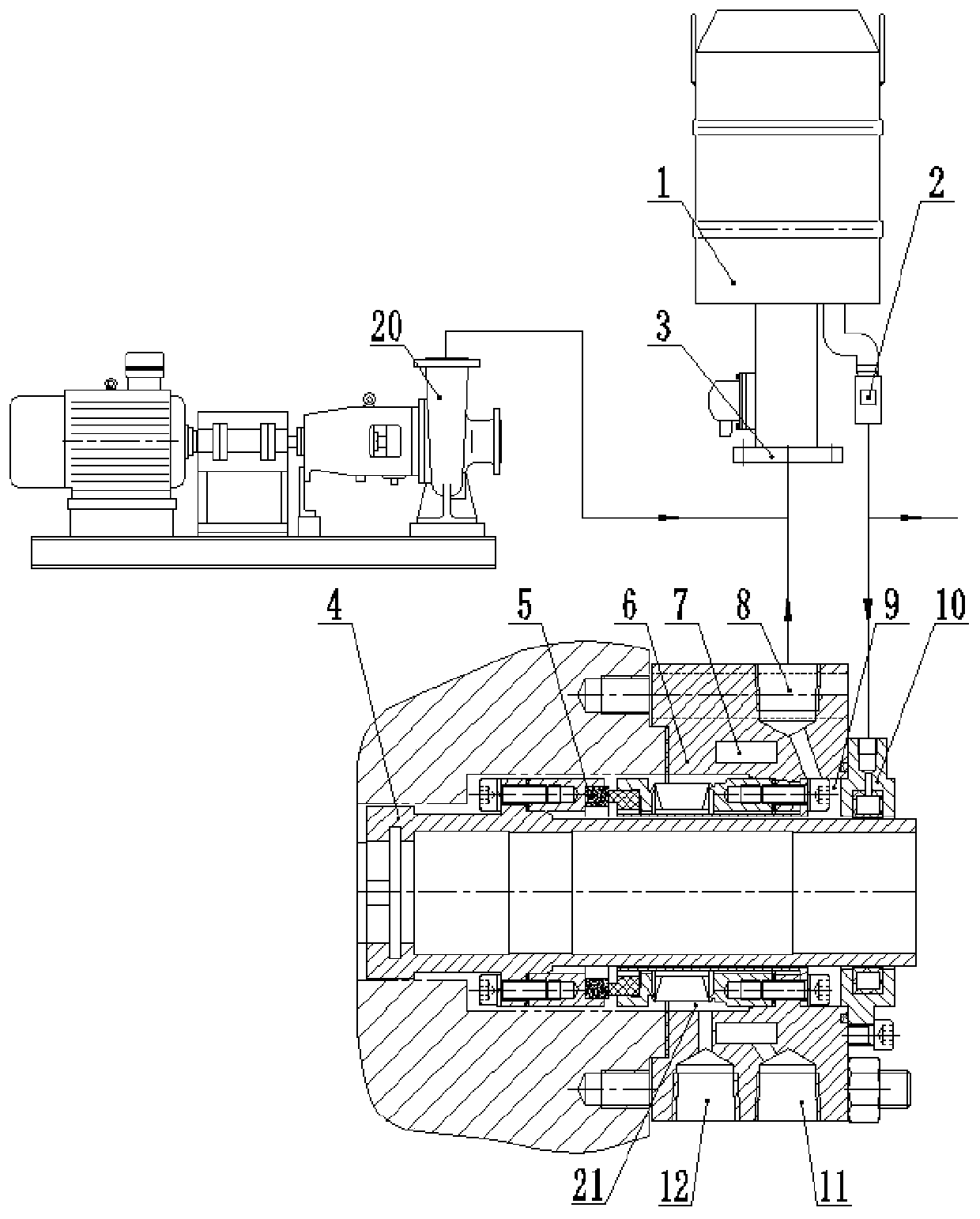

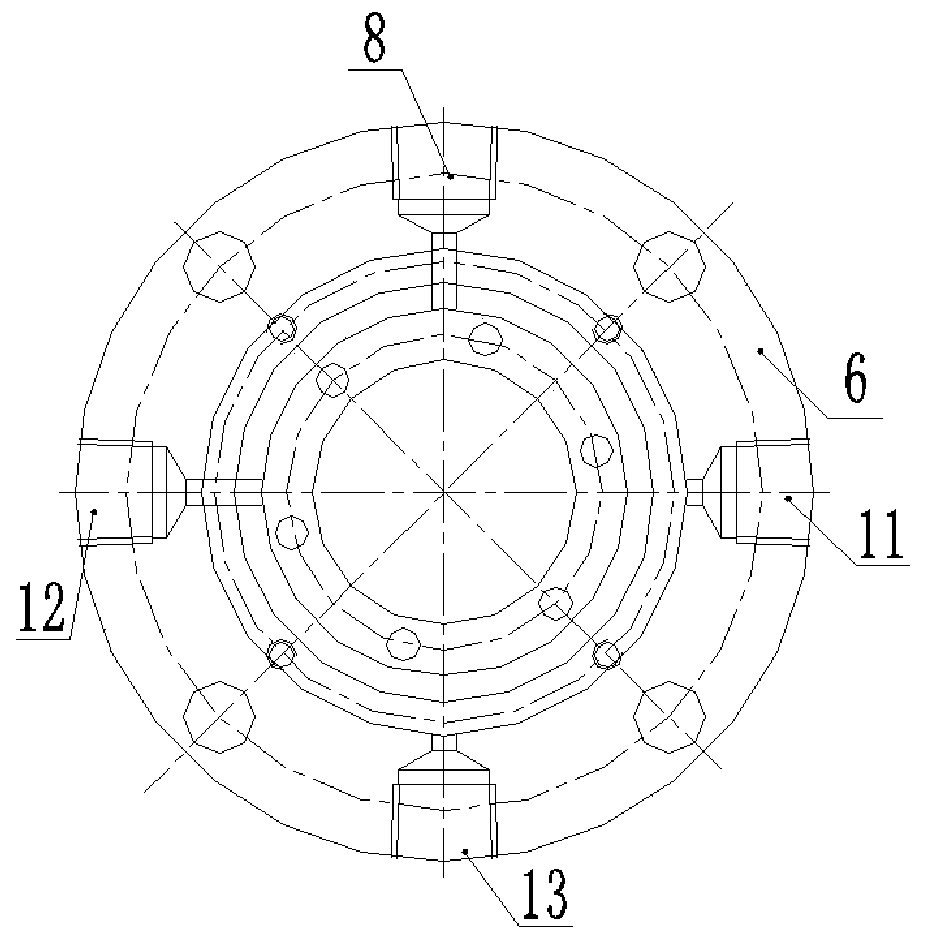

[0023] Such as figure 1 , image 3 , Figure 4 and Figure 5 As shown, the self-priming pump is mechanically sealed under positive and negative pressure conditions, including a sealing gland 6 and a shaft sleeve 4, an inner hole is opened on the back of the sealing gland 6, and a negative pressure chamber seal 10 is arranged in the inner hole, and The negative pressure chamber seal 10 is fixedly installed with the sealing gland 6 through bolts. The sealing gland 6 is processed with an independent hollow quenching chamber 7. The sealing gland 6 is fixed and installed on the pump cover through bolts. The shaft sleeve 4 is installed on the pump cover. On the shaft and through the inner hole of the sealing gland 6, the outer sleeve of the shaft sleeve 4 is provided with a bellows mechanical seal 5, the moving ring of the bellows mechanical seal 5 and the shaft sleeve 4 are fixed and installed by bolts, and the static ring of the bellows mechanical seal 5 passes through The bolt...

Embodiment 2

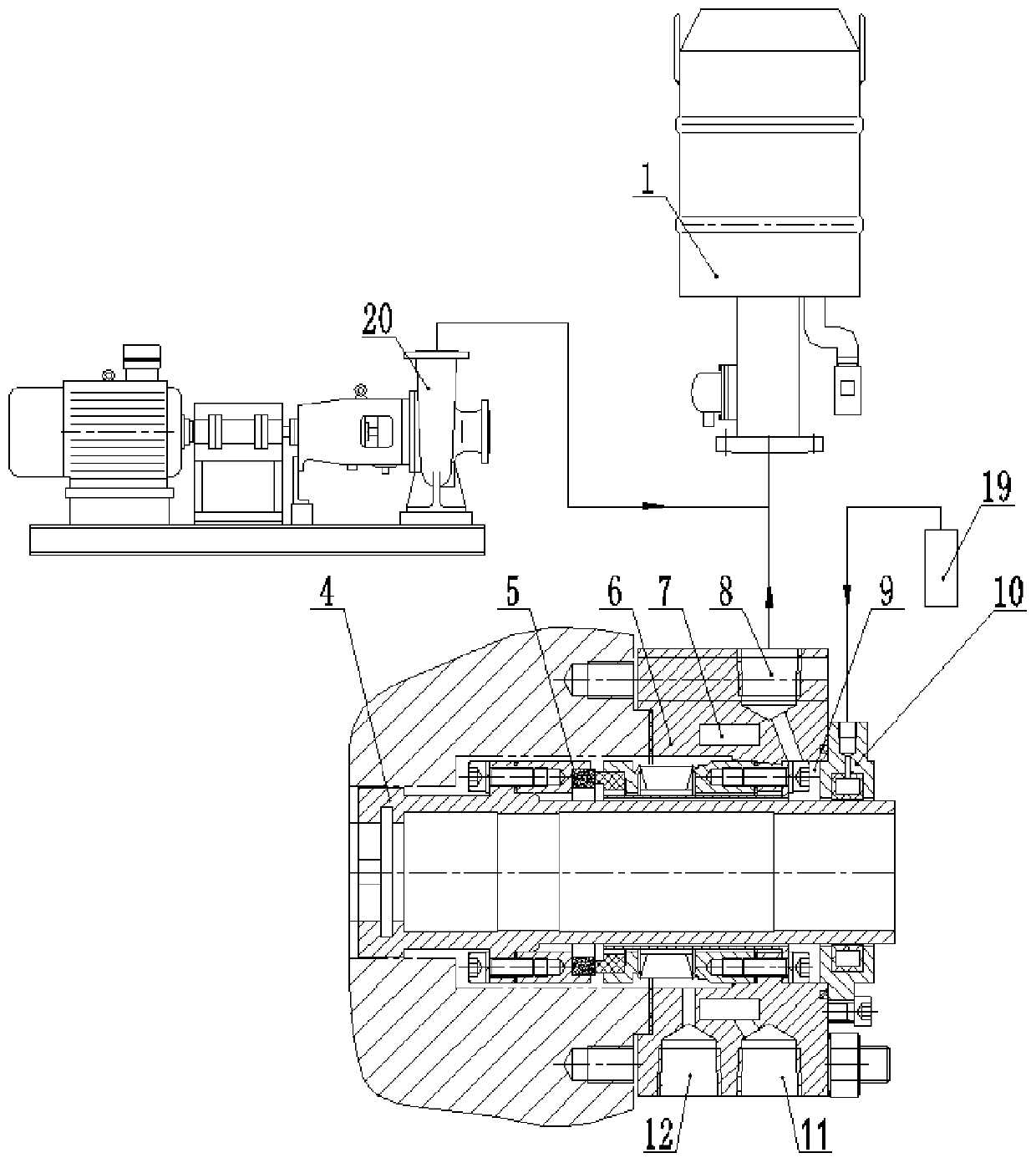

[0029] Such as figure 2 , image 3 , Figure 4 and Figure 5 As shown, the difference between Embodiment 2 and Embodiment 1 is that the inflation hole 14 of the negative pressure chamber seal 10 is connected to the external air source 19, the air bag 16 is inflated by the external air source 19, and the air bag 16 is inflated by the external air source. The source 19 inflates the airbag 16 so that the inner hole of the airbag 16 shrinks, and the inner wall of the airbag 16 tightens the outer circle of the shaft sleeve 4 to realize the sealing of the negative pressure chamber seal 10 to the negative pressure chamber 9 . All the other parts are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com