Integral pre-tightening insulation method for central cylinder of plate-type annular field coil

A field coil and hoop technology, applied in the field of pre-tightening process, to achieve the effect of good insulation effect and good insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below by means of the accompanying drawings and specific embodiments.

[0024] The essence of the method is to install the prestressed fiberglass insulation cylinder on the workpiece.

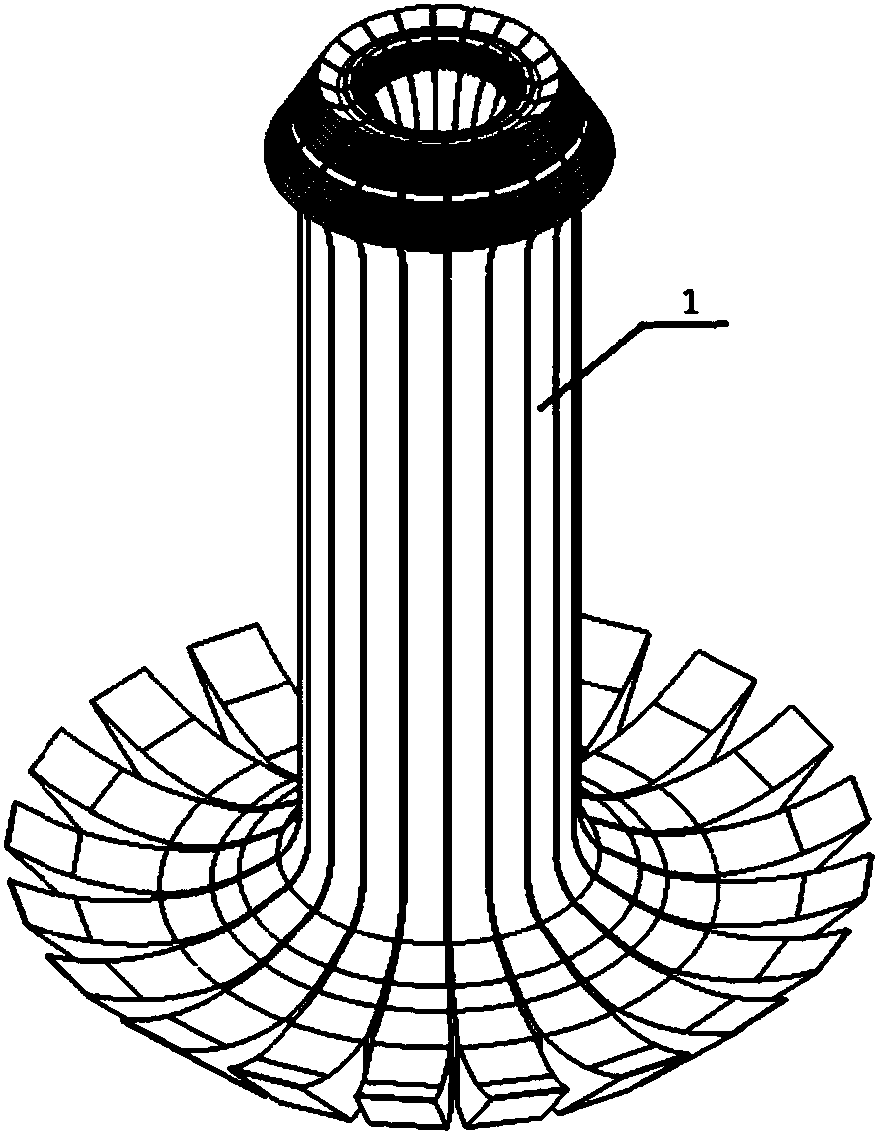

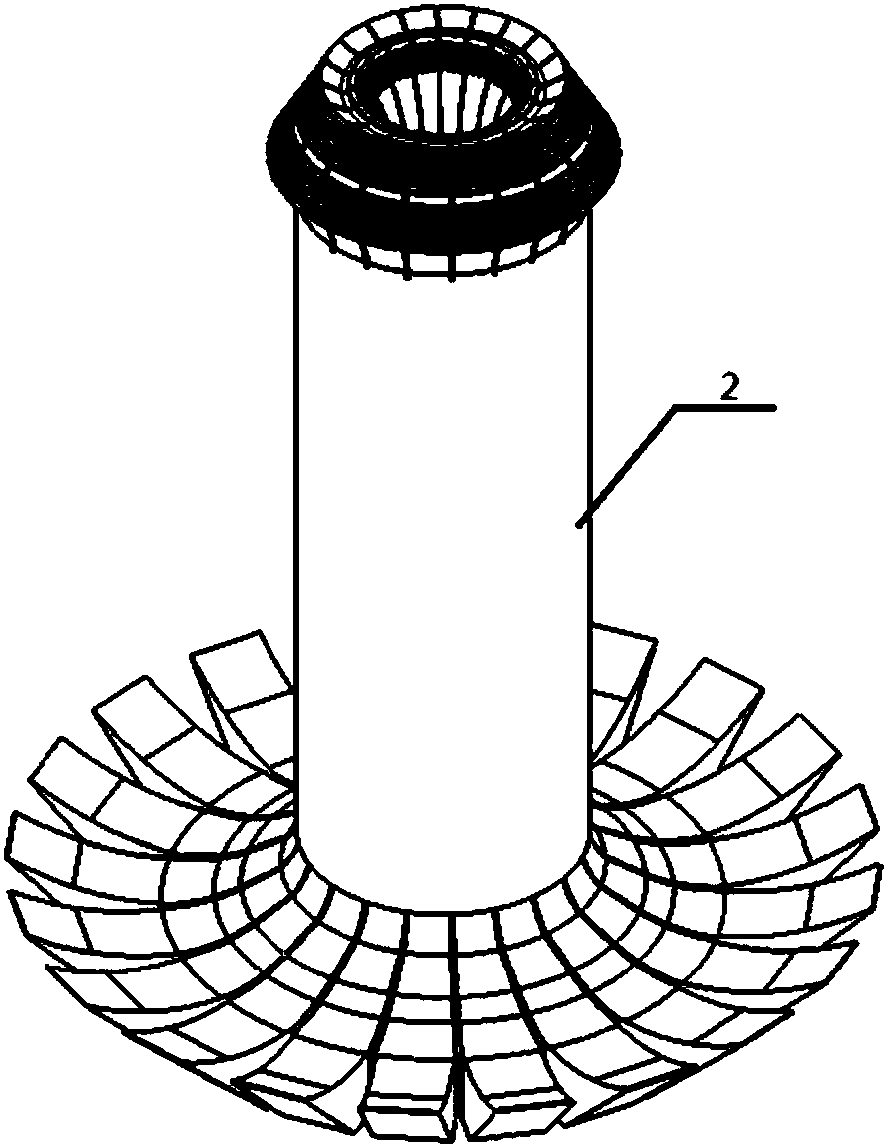

[0025] The central cylinder of the plate-type toroidal field coil is composed of 20 central section components 1, which become the workpiece in this method. The 20 central section components are combined into a cylinder, and the components are filled with epoxy plates and epoxy glue. The height of the central section assembly is 5.08 meters, the height of the prestressed insulating cylinder 2 is 3.8 meters, the inner diameter is 1.35 meters, and the net thickness is 25 mm.

[0026] The concrete steps of this method are as follows:

[0027] 1) Place a single disc of high-strength dipped glass ribbon (the preferred model is HW200, with a thickness of 0.3mm and a width of 50mm) on the tension machine;

[0028] 2) Fix and install the workpiec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com