Winding auxiliary device for lithium battery production

An auxiliary device, lithium battery technology, applied in the direction of secondary batteries, electrochemical generators, circuits, etc., can solve the problems of poor practicability and inability to screen pole pieces, etc., and achieve high practicability, novel design and reasonable structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

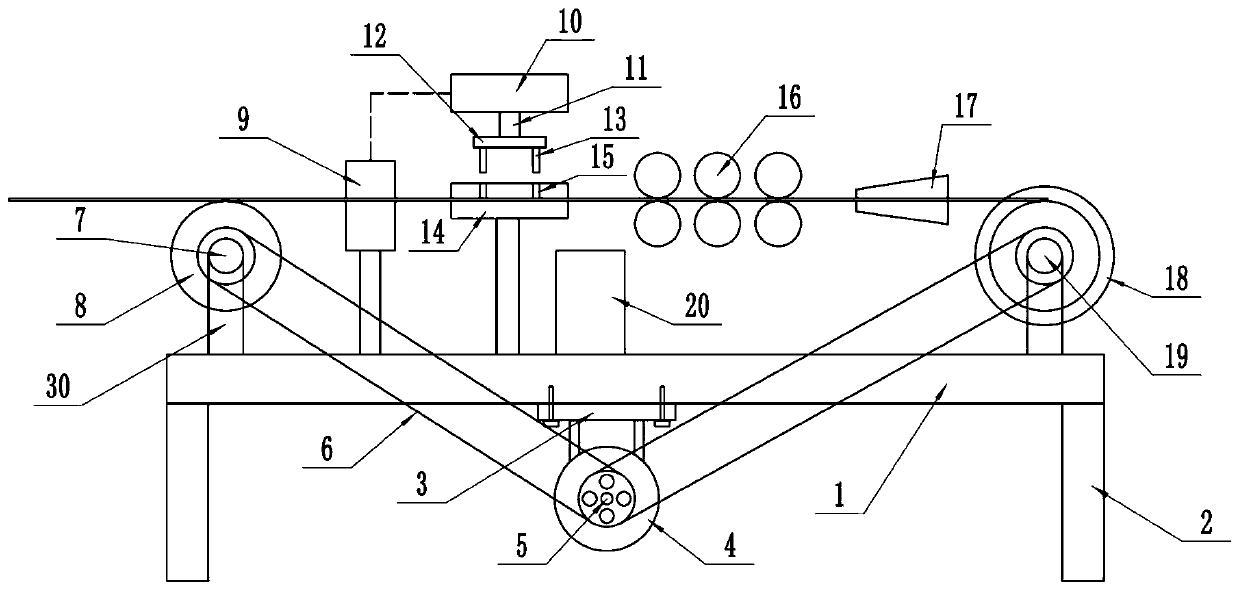

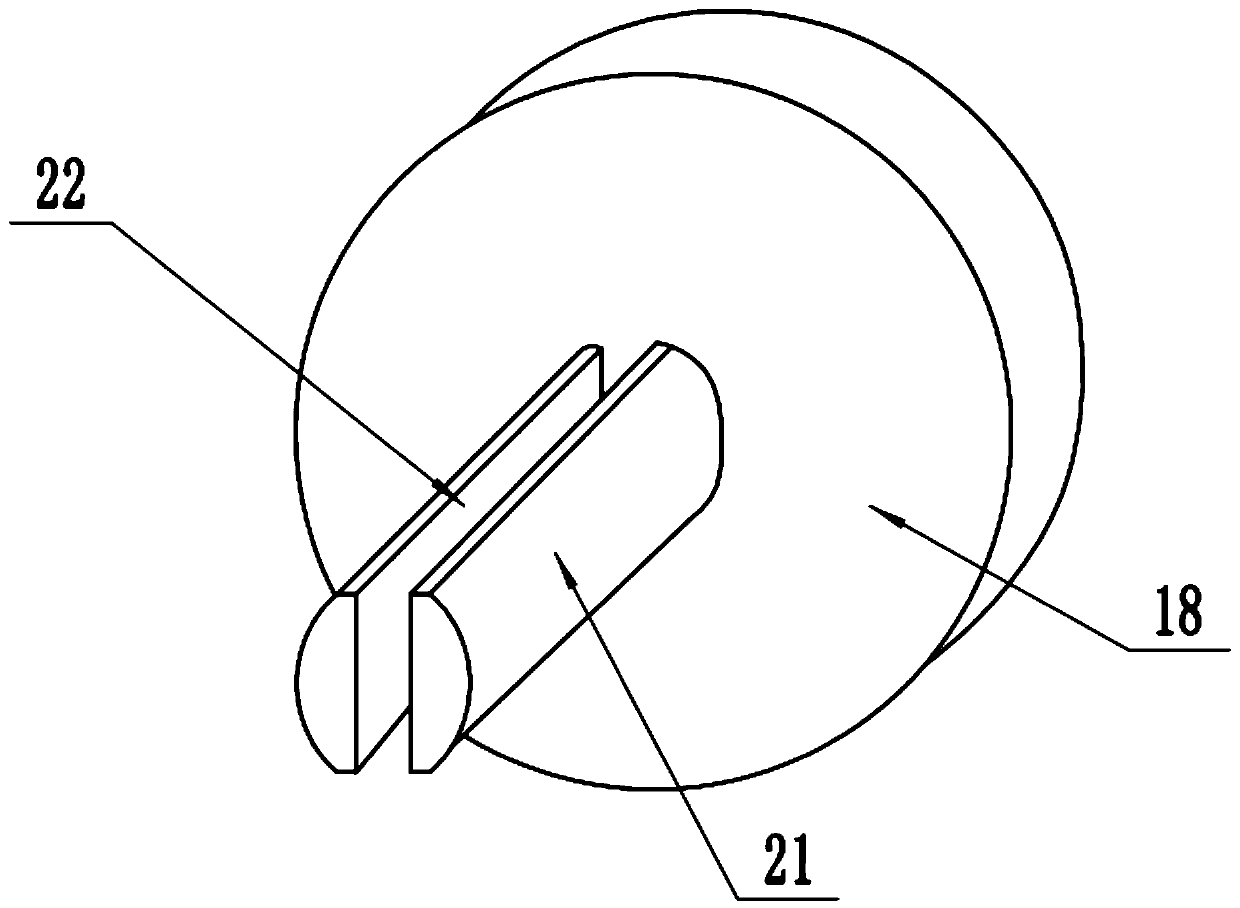

[0028] refer to figure 1 and image 3 , in an embodiment of the present invention, a winding auxiliary device for lithium battery production, including a fixed bottom plate 1, and support legs 2 are installed on both sides of the lower end of the fixed bottom plate 1, for realizing the support and fixation of the entire device, the fixed bottom plate 1 Motor base 3 is installed on both sides of bottom plate 1 lower end, is used to realize the installation and fixation to drive motor 4, and motor base 3 lower end is connected with drive motor 4, and the output shaft of described drive motor 4 is connected with drive pulley 5, drive pulley 5 The two ends are respectively connected with the driven pulley provided at the front end of the transmission shaft 7 and the transmission shaft 19 through the belt 6, so that the driving pulley 4 can rotate the transmission shaft 7 and the transmission shaft 19 synchronously through the action of the belt 6, and the fixed Support frame 30 i...

Embodiment 2

[0031] In another embodiment of the present invention, the difference between this embodiment and the above-mentioned embodiment is that a collection box 20 is provided on the lower side of the right end of the cutting mechanism, and the collection box 20 is fixed on the upper end of the fixed bottom plate 1, and the collection box 20 is set. The material bin 20 is used to cut and screen out the cracked pole pieces.

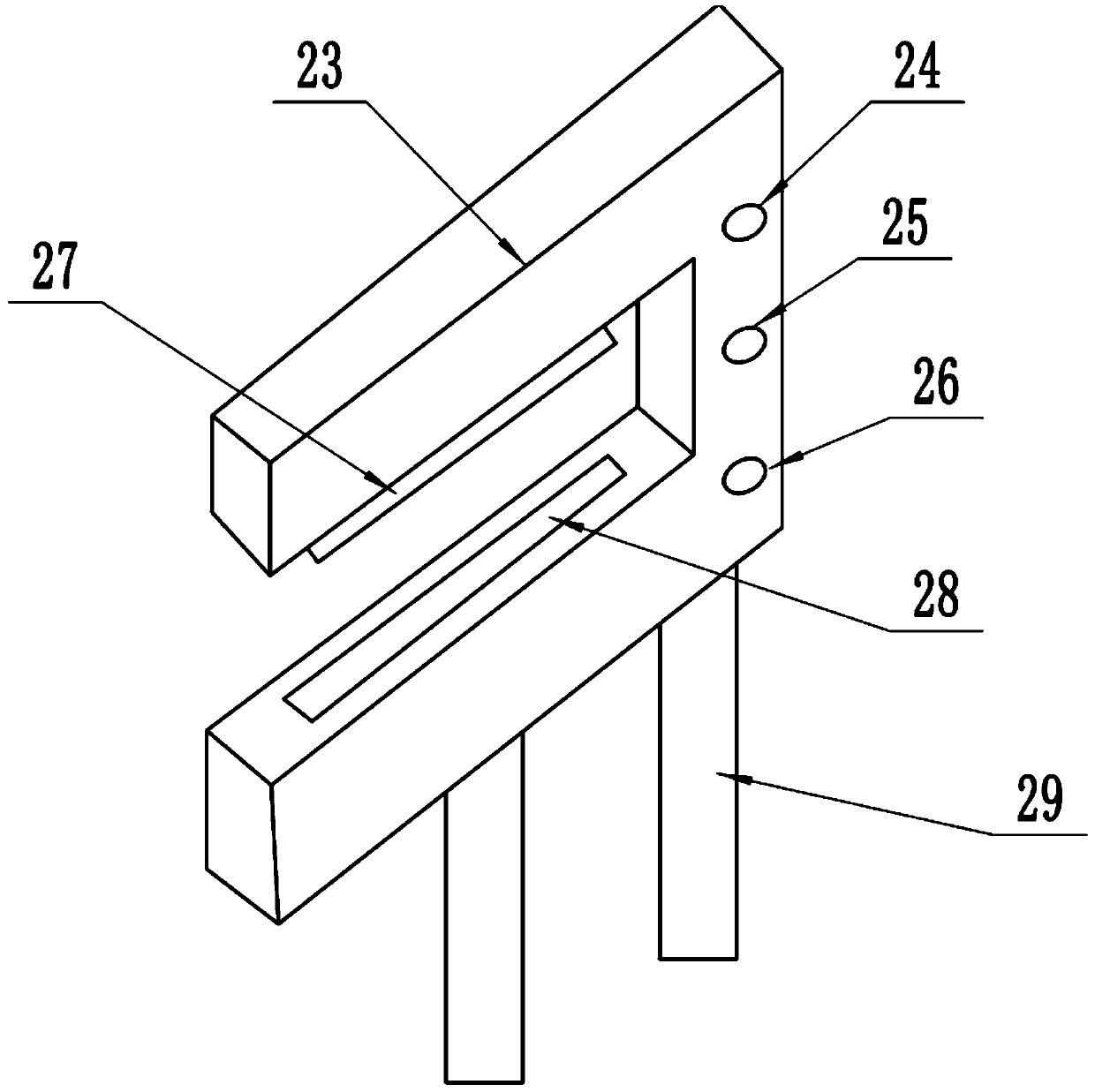

[0032] In the present invention, when working, the pole piece is passed through the conveying wheel 8, the detection mechanism 9, the truncation block, the flattening roller group 16, the flattening block 17, and then connected to the fixed groove in the middle of the winding shaft 21 at the front end of the winding wheel 18 22, then start the drive motor 4 to realize the winding effect on the pole piece, when there is a rupture in a certain place in the middle of the pole piece, the energy signal sent by the ultrasonic transmitter 27 will not be reduced and will ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com