Microchannel plate based on cross-shaped curve, gas-liquid reactor and reaction system and application

A gas-liquid reactor and microchannel plate technology, which is applied in chemical instruments and methods, chemical/physical processes, etc., can solve the problems of slow heating, slow heat dissipation, and limited mass transfer in gas-liquid reaction, so as to improve productivity and Selectivity, improve efficiency, enhance the effect of mass transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

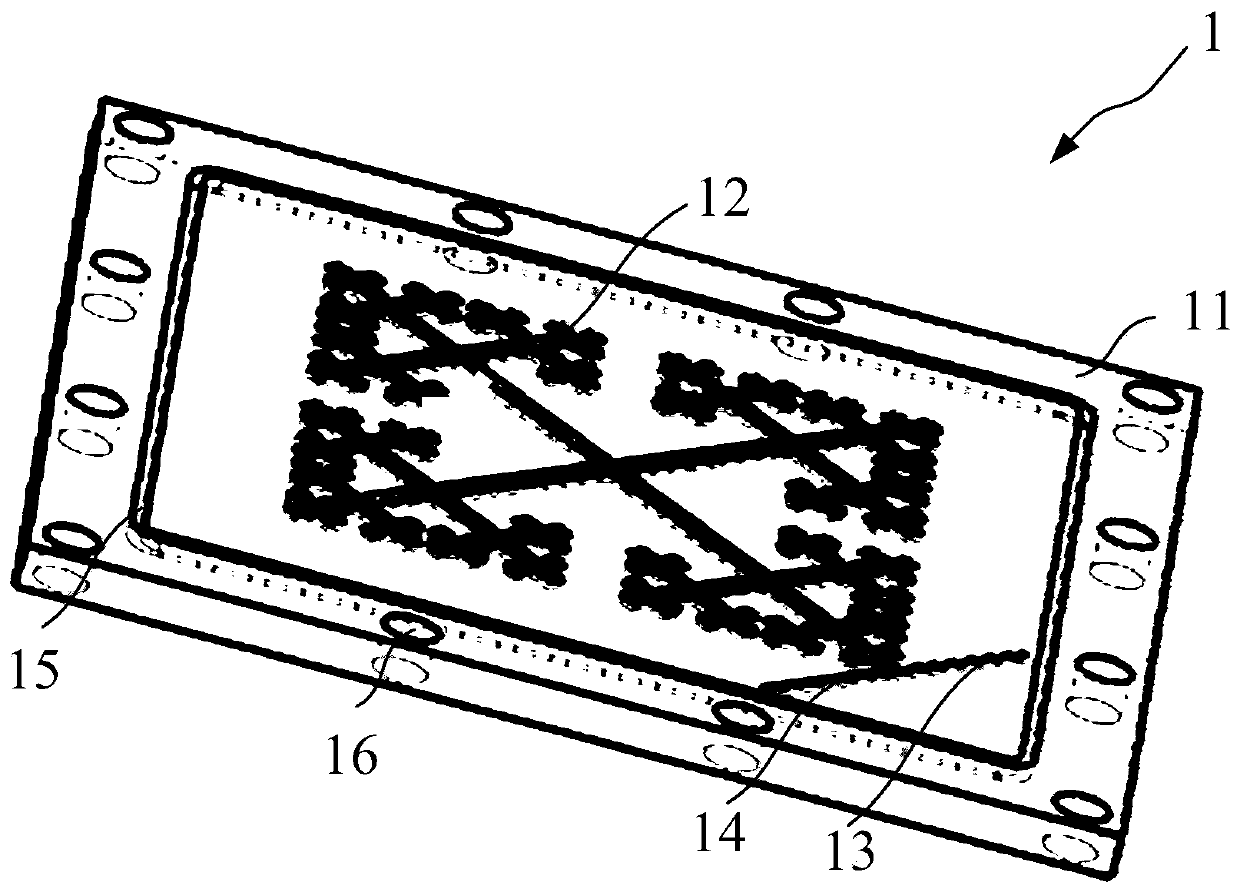

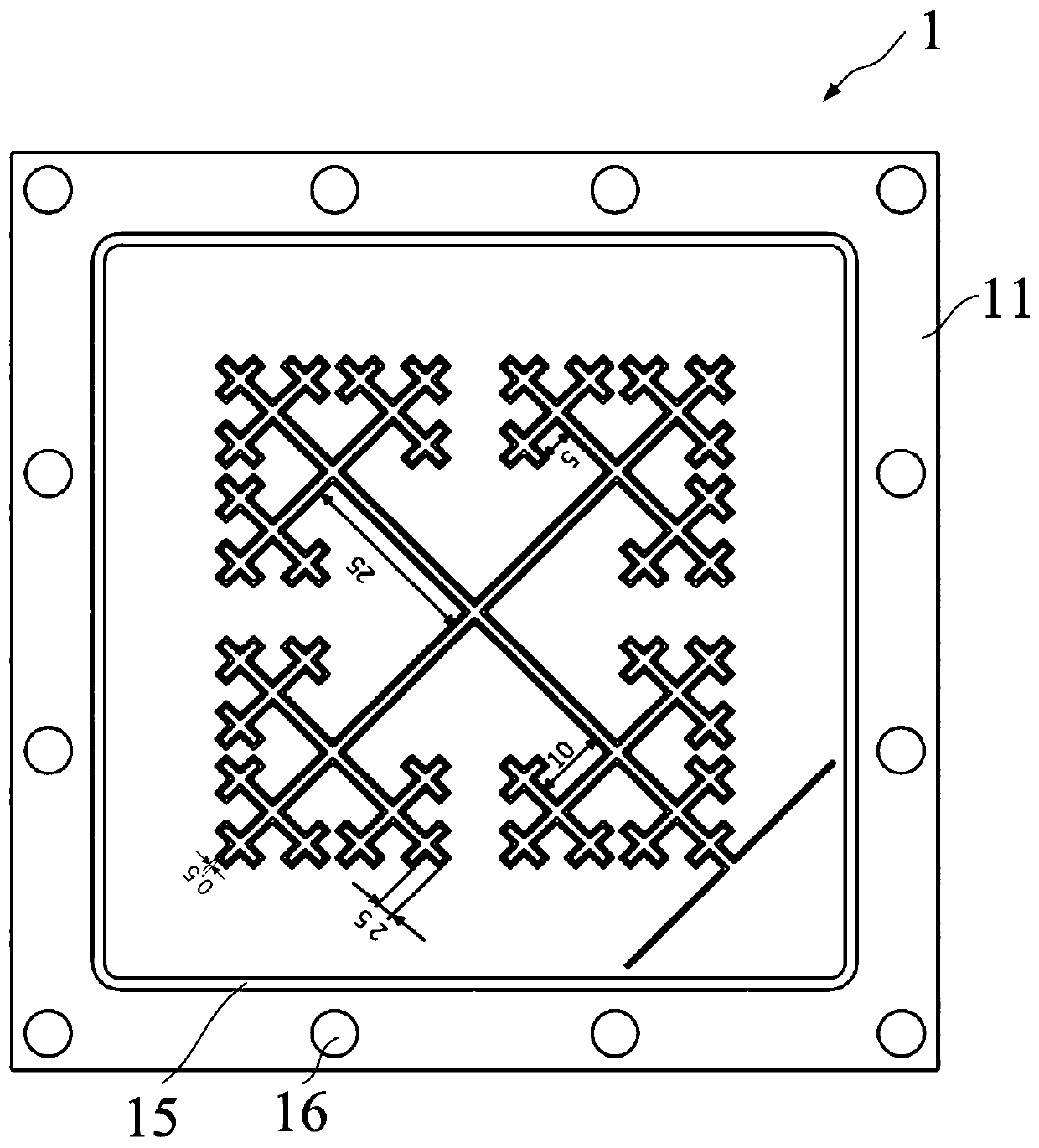

[0063] Such as figure 1As shown, the present embodiment provides a microchannel plate 1 based on a cross curve, and the microchannel plate based on a cross curve comprises:

[0064] Reaction plate 11 , cross fractal structure microchannel 12 , input microchannel 13 and output microchannel 14 .

[0065] Such as figure 1 As shown, the reaction plate 11 is used to form reaction channels.

[0066] Specifically, in this embodiment, the reaction plate 11 is a rectangular structure, the size of which includes but is not limited to 120mm*120mm, and the thickness of the reaction plate 11 includes but is not limited to 5mm. In actual use, the reaction plate 11 The shape, size and thickness can be set as required, and are not limited to this embodiment. In this embodiment, the microchannel plate 1 based on the cross curve is used for the homogeneously catalyzed olefin hydroformylation reaction, and the material of the reaction plate 11 is selected as polytetrafluoroethylene. In actual...

Embodiment 2

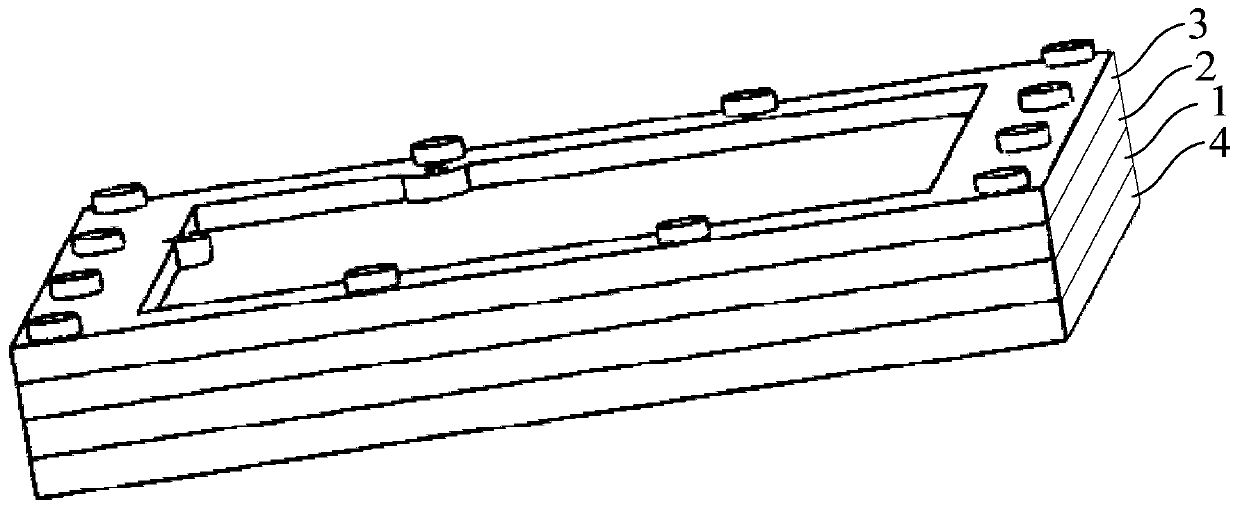

[0079] Such as image 3 As shown, the present embodiment provides a gas-liquid reactor, and the gas-liquid reactor includes:

[0080] Microchannel plate 1 and cover plate 2 based on the cross curve.

[0081] Such as image 3 As shown, the microchannel plate 1 based on the cross curve is firmly connected with the cover plate 2 .

[0082] Specifically, the specific structure of the microchannel plate 1 based on the cross curve is as described in Embodiment 1, and will not be repeated here. The microchannel plate 1 based on the cross curve has the surface of the cross fractal structure microchannel 12 opposite to the cover plate 2. In this embodiment, the cross fractal structure microchannel 12 is formed on the cross-based microchannel 12. The upper surface of the microchannel plate 1 is curved, and the upper surface of the microchannel plate 1 based on a cross curve is attached to the lower surface of the cover plate 2 .

[0083] Such as image 3 As shown, the cover plate 2...

Embodiment 3

[0093] Such as Figure 1 to Figure 5 As shown, the present embodiment provides a gas-liquid reaction system, and the gas-liquid reaction system includes:

[0094] Feeding device and gas-liquid reactor.

[0095] Such as Figure 1 to Figure 5 As shown, the feeding device is connected with the reaction gas and the reaction liquid, and transports the gas-liquid two-phase of the reaction gas and the reaction liquid to the input through hole 21 of the gas-liquid reactor.

[0096] Specifically, the feeding device includes a three-way valve, a flow meter and a peristaltic pump. The reaction gas is connected to the first port of the three-way valve through a gas pipeline, the flow meter is connected to the gas pipeline, and the flow meter is used to control the flow of the reaction gas. The reaction liquid is connected to the second port of the three-way valve through a liquid pipeline, the peristaltic pump is connected to the liquid pipeline, and the peristaltic pump is used to tra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com