Real-time printing automatic labeling device and automatic labeling method thereof

A code sticking and equipment technology, applied in the field of real-time printing and automatic code sticking equipment, can solve problems such as the inability to apply automatic code sticking to bags, the inability to achieve multiple bags equidistant and other time to take bags, etc. Simple, tremor-free effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

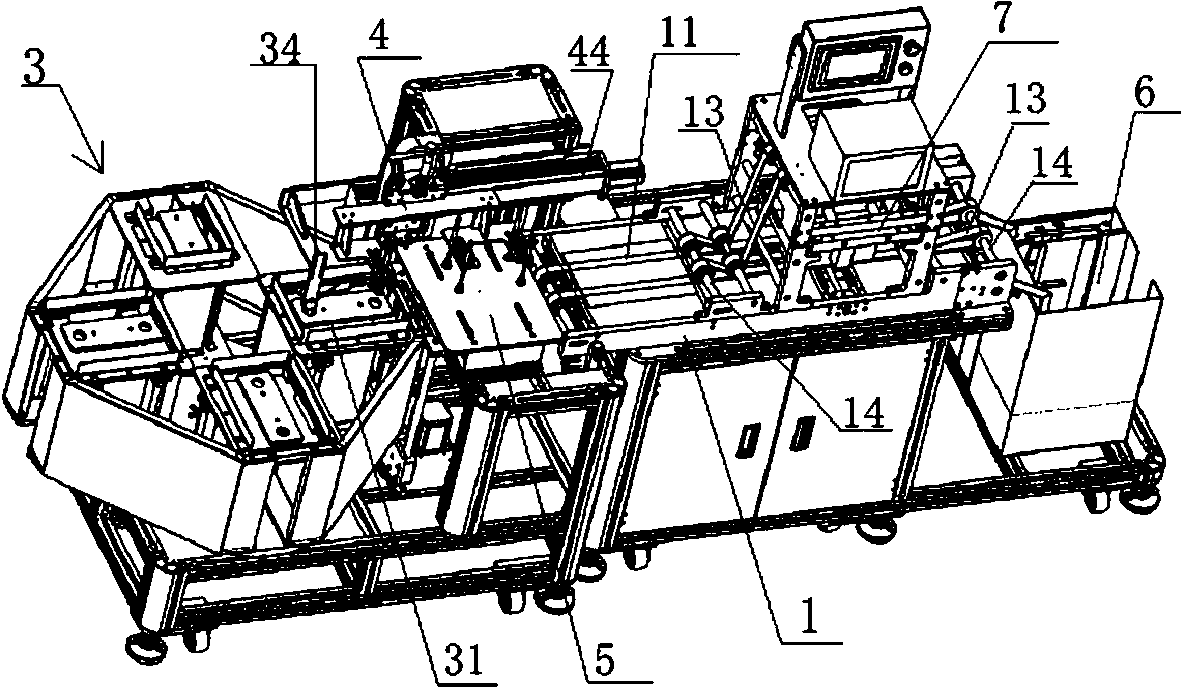

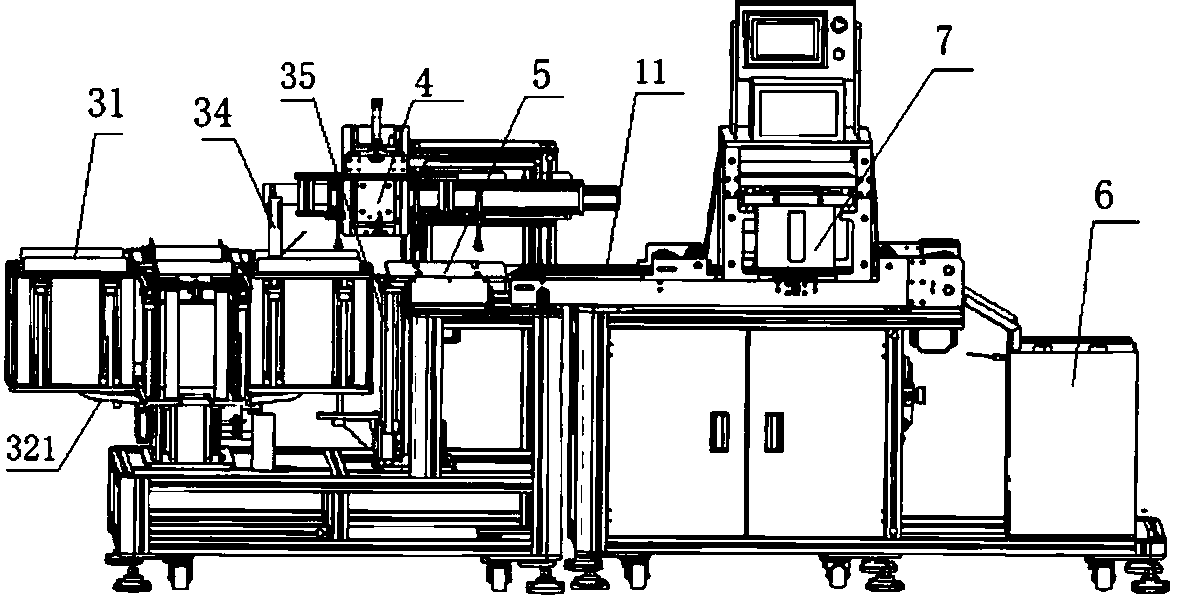

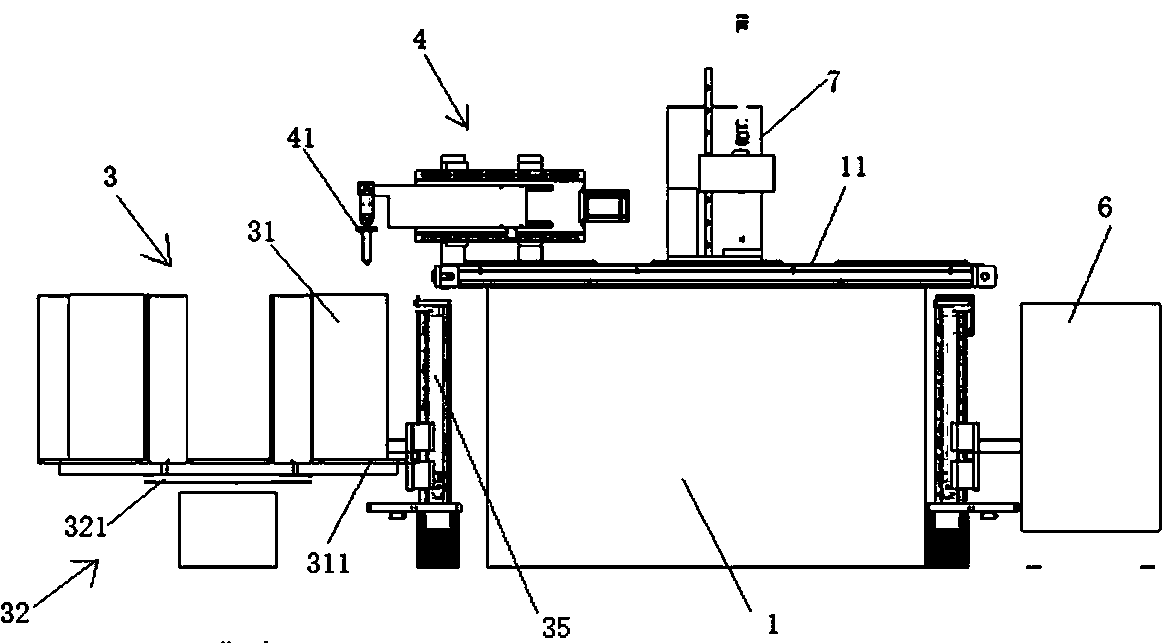

[0047] see Figure 1 to Figure 7 , a real-time printing automatic labeling equipment, including

[0048] Workbench 1, thermal transfer machine 7, bag type selection mechanism 3, bag taking mechanism 4 and control device;

[0049] A conveyor belt 11 is placed on the upper surface of the workbench 1;

[0050] The thermal transfer machine 7 is placed on the workbench 1, and receives the printing information and transfers it on the bag surface before or during the working process of the printing automatic labeling equipment;

[0051] The bag type selection mechanism 3 is arranged outside the conveying start end of the conveyor belt 11, and it has a plurality of bins 31 for stacking different types of bags and adjusts the bins 31 so that one of the bins 31 is located at the working position of the bag taking mechanism 4. Position adjusting warehouse component 32;

[0052] The bag taking mechanism 4 is arranged between the bag model selection mechanism 3 and the conveyor belt 11,...

Embodiment 2

[0068] see Figure 8 , also refer to figure 1 , a real-time printing automatic labeling equipment, including

[0069] Workbench 1, thermal transfer machine 7, bag type selection mechanism 3, bag taking mechanism 4 and control device;

[0070] A conveyor belt 11 is placed on the upper surface of the workbench 1;

[0071] The thermal transfer machine 7 is placed on the workbench 1, and receives the printing information and transfers it on the bag surface before or during the working process of the printing automatic labeling equipment;

[0072] The bag type selection mechanism 3 is arranged outside the conveying start end of the conveyor belt 11, and it has a plurality of bins 31 for stacking different types of bags and adjusts the bins 31 so that one of the bins 31 is located at the working position of the bag taking mechanism 4. Position adjusting warehouse component 32;

[0073] The difference between embodiment two and embodiment one mainly lies in:

[0074] The bag tak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com