Method for removing dispersant on surface of carbon nanotube by vacuum evaporation

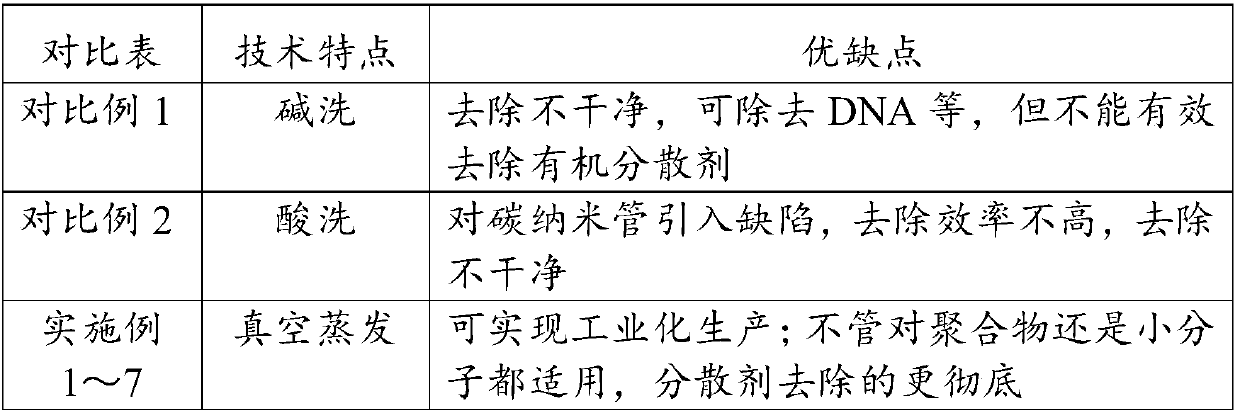

A technology for removing carbon nanotubes and surface dispersants, applied in the direction of carbon nanotubes, nanocarbons, etc., can solve the problems of polymer pollution, low efficiency, instability, etc., to achieve easy industrial production, simple steps, reliable and stable process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0049] In the second embodiment provided by the present invention, the polymer dispersant on the surface of the carbon nanotubes can be removed by using the principle of cracking the polymer with an acidic solution and the principle of vacuum evaporation.

[0050] According to the third embodiment of the present invention, there is provided a method for removing the dispersant on the surface of carbon nanotubes by vacuum evaporation, which is used to remove the dispersion liquid containing the small molecule dispersant and the dispersant containing the polymer dispersant on the surface of the carbon nanotubes. Dispersions.

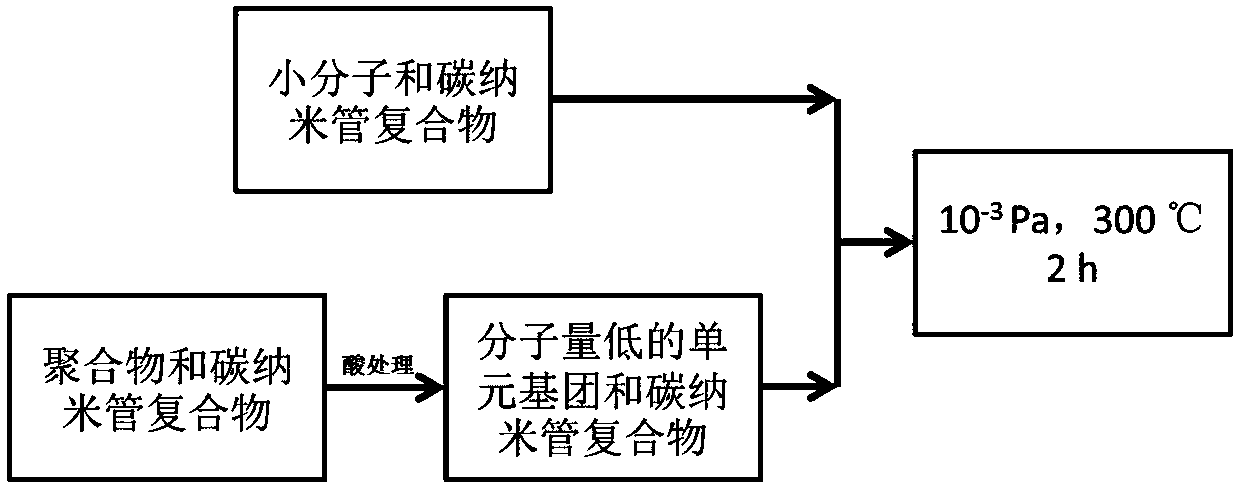

[0051] The following will refer to figure 1 , to describe in detail the specific implementation steps of the third embodiment.

[0052] For carbon nanotubes with a dispersion liquid containing a small molecule dispersant and a dispersion liquid containing a polymer dispersant attached to the surface, first, the dispersion liquid containing a small molecul...

Embodiment 1

[0060] Step 1: Suction filter or evaporate the dispersion liquid containing small molecule dispersant to obtain solid powder or solid film; Step 2: Put the solid powder or solid film obtained in step 1 into the vacuum heating equipment, set the temperature at 300 ℃, vacuum degree 10 -3 Pa, time 2h, after the temperature of the vacuum chamber drops to room temperature, take out the sample.

Embodiment 2

[0062] Step 1: Suction filter or evaporate the dispersion liquid containing small molecule dispersant to obtain solid powder or solid film; Step 2: Put the solid powder or solid film obtained in step 1 into the vacuum heating equipment, set the temperature at 200 ℃, vacuum degree 10 -2 Pa, time 0.5h, after the temperature of the vacuum chamber drops to room temperature, take out the sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com