Glass ceramic for up-conversion laser solid illumination, preparation method thereof and solid illuminating device

A technology of solid-state lighting and glass ceramics, applied in glass manufacturing equipment, optical elements for changing the spectral characteristics of emitted light, and components of lighting devices, etc., can solve problems such as sudden drop in efficiency and difficulty in realization, and achieve low cost , simple device structure and easy fabrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: SiO 2 、Al 2 o 3 、Na 2 CO 3 , NaF, YbF 3 , YF 3 and ErF 3 According to 62SiO 2 : 6Al 2 o 3 : 5Na 2 CO 3 :19NaF:1.6YbF 3 : 6.24YF 3 : 0.16ErF 3 The ratio (molar ratio) is accurately weighed, ground evenly in an agate mortar, placed in a crucible, heated to 1500°C in a resistance furnace, and kept for 45 minutes, and then the molten glass is quickly poured into a 500°C preheated Forming in a copper mold; the annealed glass continues to be heated and kept at 650 ° C for 2 hours to crystallize it to obtain Yb 3+ / Er 3+ Doped NaYF 4 Embedded transparent glass-ceramic composite.

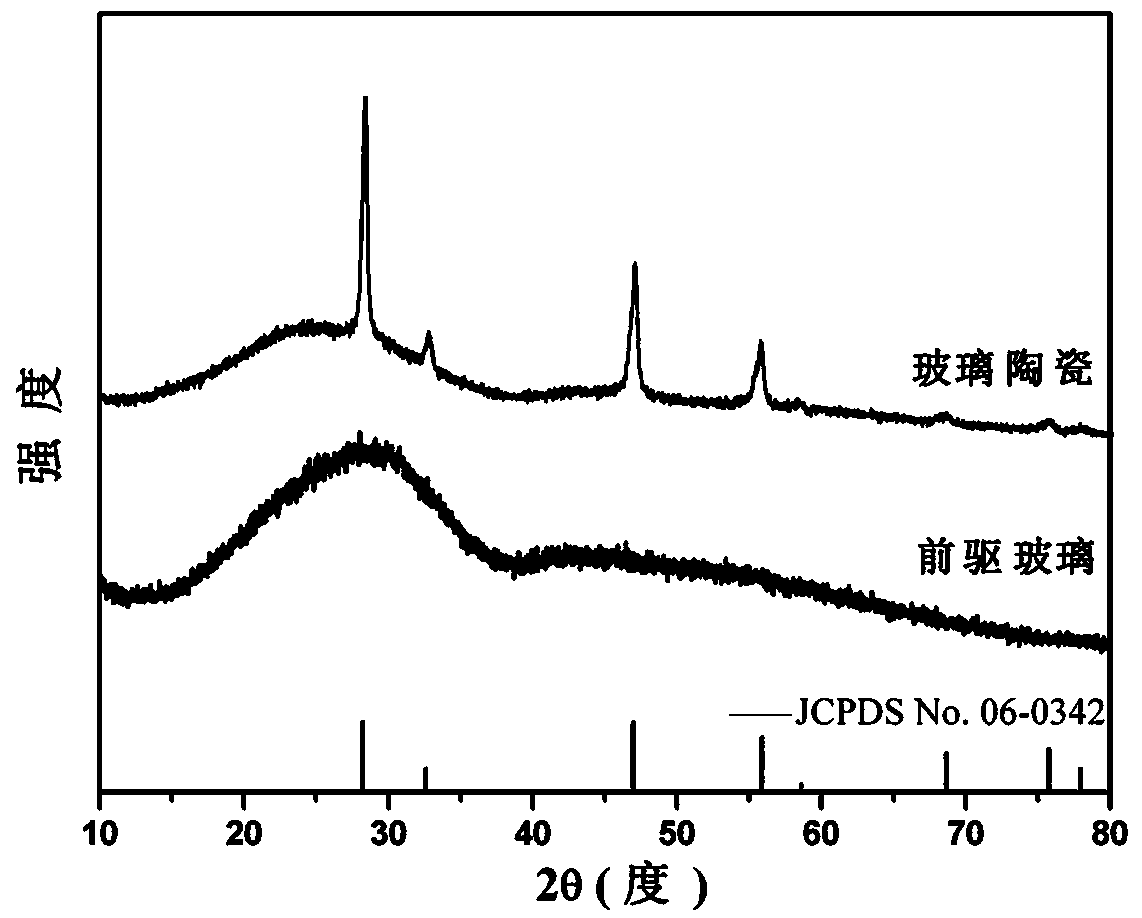

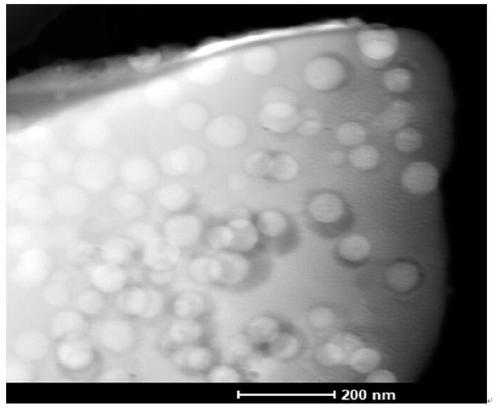

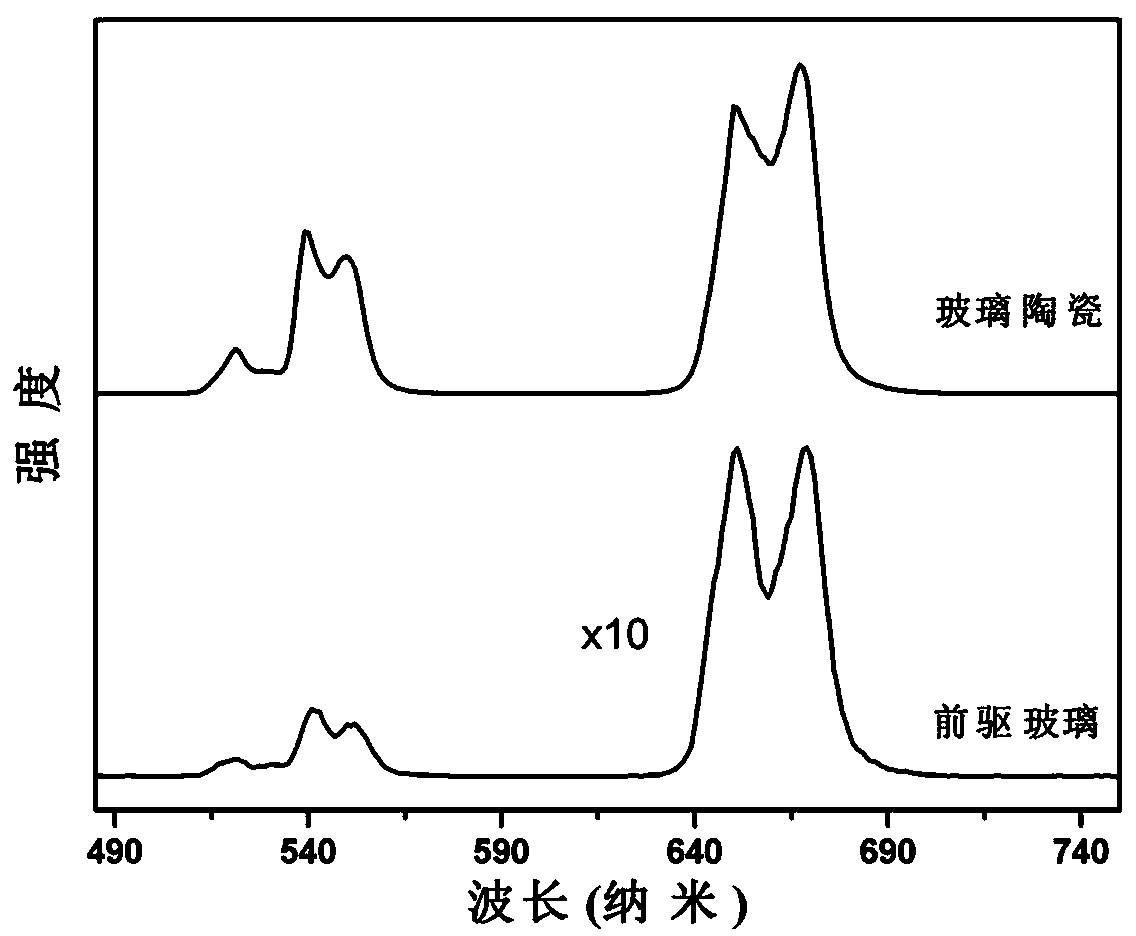

[0034] X-ray Diffraction Patterns Show Cubic NaYF Precipitated in Aluminosilicate Glass Substrate 4 crystal phase ( figure 1 ); transmission electron microscopy photos show that there are a large number of NaYF with a size of about 20nm evenly distributed in the glass ceramics 4 crystal phase ( figure 2 ), the glass ceramic emits yellow light under excitation at 98...

Embodiment 2

[0035] Embodiment 2: SiO 2 、Al 2 o 3 、Na 2 CO 3 , NaF, YbF 3 , YF 3 and ErF 3 According to 55SiO 2 : 6Al 2 o 3 : 12Na 2 CO 3 :19NaF:1.6YbF 3 : 6.24YF 3 : 0.16ErF 3 The ratio (molar ratio) is accurately weighed, ground evenly in an agate mortar, placed in a crucible, heated to 1450°C in a resistance furnace and kept for 45 minutes, and then quickly poured the molten glass into a 500°C preheated Forming in a copper mold; the annealed glass continues to be heated and kept at 650 ° C for 2 hours to crystallize it to obtain Yb 3+ / Er 3+ Doped NaYF 4 Embedded transparent glass-ceramic composite.

[0036] X-ray Diffraction Patterns Show Hexagonal NaYF Precipitated in Aluminosilicate Glass Substrate 4 crystal phase ( Figure 4 ); transmission electron microscopy photos show that there are a large number of NaYF with a size of about 20nm evenly distributed in the glass ceramics 4 crystal phase ( Figure 5 ), the glass ceramic emits green light under excitation at 9...

Embodiment 3

[0037] Embodiment 3: SiO 2 、Al 2 o 3 、Na 2 CO 3 , NaF, YbF 3 , YF 3 and ErF 3 According to 55SiO 2 : 6Al 2 o 3 : 12Na 2 CO 3 :19NaF:1.6YbF 3 : 6.38YF 3 : 0.02TmF 3 The ratio (molar ratio) is accurately weighed, ground evenly in an agate mortar, placed in a crucible, heated to 1500°C in a resistance furnace, and kept for 45 minutes, and then the molten glass is quickly poured into a 500°C preheated Forming in a copper mold; the annealed glass continues to be heated and kept at 650 ° C for 2 hours to crystallize it to obtain Yb 3+ / Tm 3+ doped hexagonal NaYF 4 Embedded transparent glass-ceramic composite. Glass ceramics emit blue light under 980nm laser excitation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com