TRD continuous wall curing agent, and use method and application thereof

A curing agent and sulfonated oil technology, which is applied in sea area engineering, construction, protection devices, etc., can solve the problems of affecting soil curing performance, insufficient compatibility, and insufficient water repellency, so as to improve the setting time and compressive strength , Short construction period and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

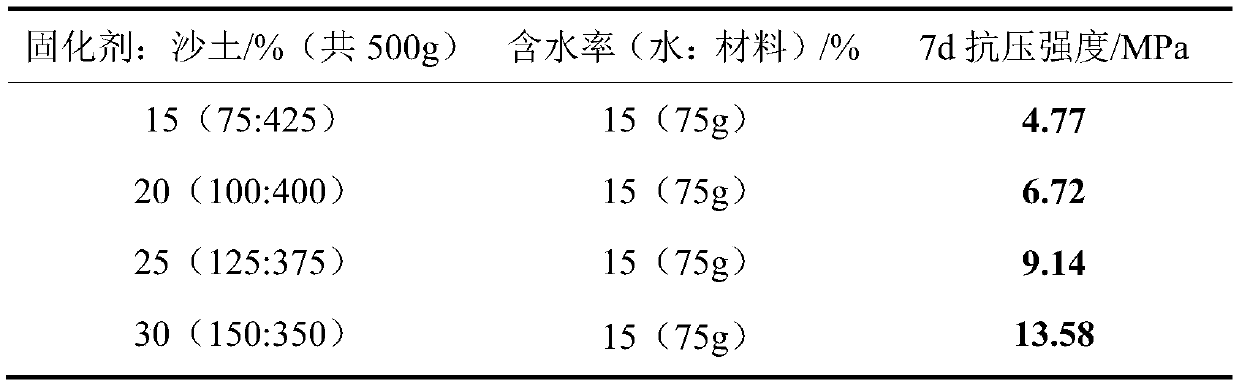

Examples

Embodiment 1

[0058] A preparation method of TRD continuous wall curing agent, comprising the steps of:

[0059] (1) In terms of parts by mass, weigh 15 parts of sodium lauryl polyoxyethylene ether sulfate, 20 parts of sulfonated oil, 2 parts of polyanionic cellulose, 10 parts of glycerin, high molecular polymer anionic surfactant 20 parts were dissolved in water, the operating temperature was 20°C, and the stirring time was 5 minutes to obtain A solution;

[0060] (2) Evenly stir 15 parts of fly ash, 5 parts of water glass, 3 parts of sodium fluorosilicate, 10 parts of cement, 10 parts of phosphogypsum, 2 parts of sulfuric acid, 5 parts of polyacrylamide, and 10 parts of water. The operating temperature is 20°C, stirring time is 5min, to obtain B slurry;

[0061] (3) 10 parts of epoxy resin and 3 parts of diethanolamine were uniformly stirred to obtain C slurry, the operating temperature was 20° C., and the stirring time was 5 min to obtain C solution;

[0062] (4) Mix A solution, B slur...

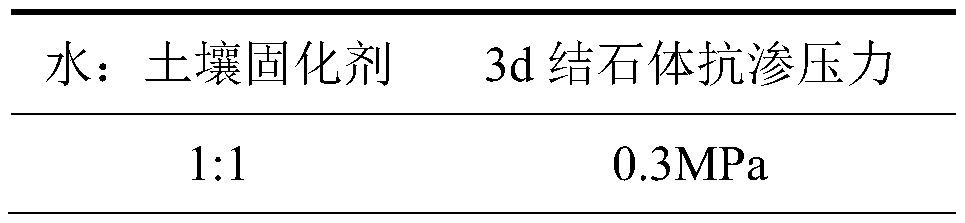

Embodiment 2

[0071] A preparation method of TRD continuous wall curing agent, comprising the steps of:

[0072] (1) In terms of parts by mass, weigh 15 parts of sodium lauryl polyoxyethylene ether sulfate, 20 parts of sulfonated oil, 2 parts of polyanionic cellulose, 10 parts of glycerin, high molecular polymer anionic surfactant 10 parts were dissolved in water, the operating temperature was 10°C, and the stirring time was 10 minutes to obtain A solution;

[0073] (2) Stir 30 parts of fly ash, 20 parts of water glass, 9 parts of sodium fluorosilicate, 40 parts of cement, 20 parts of phosphogypsum, 6 parts of sulfuric acid, 20 parts of polyacrylamide, and 20 parts of water. The operating temperature is 20°C, stirring time is 10min, to obtain B slurry;

[0074] (3) Evenly stir 15 parts of epoxy resin and 5 parts of ethylene glycol to obtain C slurry, the operating temperature is 10°C, and the stirring time is 10 minutes to obtain C solution;

[0075] (4) Mix A solution, B slurry, and C so...

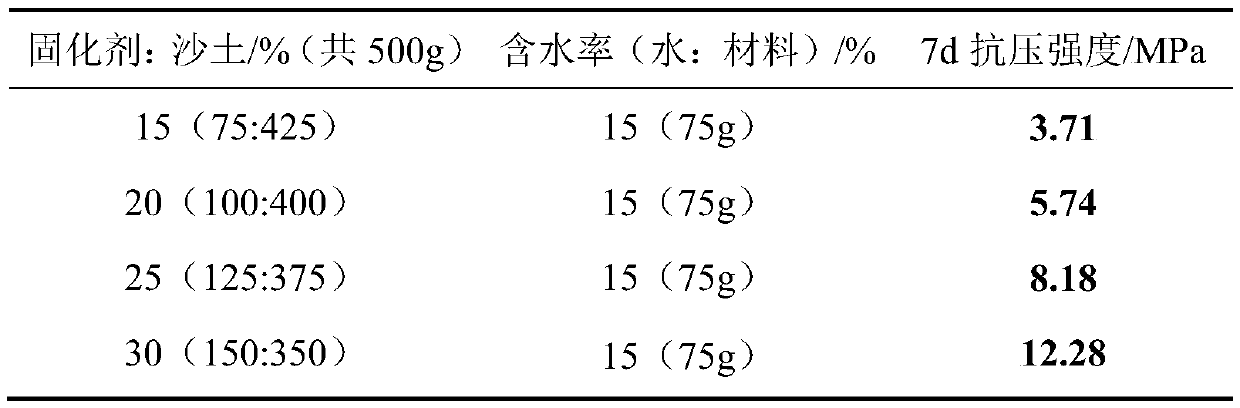

Embodiment 3

[0083] A preparation method of TRD continuous wall curing agent, comprising the steps of:

[0084] (1) In terms of parts by mass, weigh 55 parts of sodium lauryl alcohol polyoxyethylene ether sulfate, 30 parts of sulfonated oil, 8 parts of polyanionic cellulose, 50 parts of glycerin, high molecular polymer anionic surfactant 20 parts were dissolved in water, the operating temperature was 20°C, and the stirring time was 5 minutes to obtain A solution;

[0085] (2) Evenly stir 15 parts of fly ash, 5 parts of water glass, 3 parts of sodium fluorosilicate, 10 parts of cement, 10 parts of phosphogypsum, 2 parts of sulfuric acid, 5 parts of polyacrylamide, and 10 parts of water. The operating temperature is 20°C, stirring time is 5min, to obtain B slurry;

[0086] (3) Stir 15 parts of epoxy resin and 5 parts of triethanolamine evenly to obtain C slurry, the operating temperature is 20° C., and the stirring time is 5 min to obtain C solution;

[0087] (4) Mix A solution, B slurry, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com