Macromonomer containing lactam structure and its use in preparing polymer polyol

A technology of macromonomer and polyester polyol, which is applied to macromonomer with lactam structure and its preparation, and the field of preparing polymer polyol, can solve the problem of uneven appearance of polymer particles, incompatibility in performance, use of Large quantity and other problems, to achieve the effect of uniform appearance, lower production and operating costs, and low usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050]

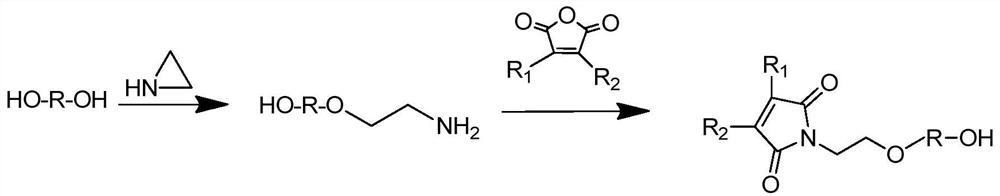

[0051] step 1)

[0052] In a reactor with a capacity of 1 liter and equipped with a stirrer, a heater, a thermocouple, a condensing device with a water separator, an inlet device and an outlet device, under nitrogen protection, add: 8.4 g of aziridine and 416.4 g of (0.2082mol) polyether polyol 2020 (Wanhua Chemical Group Co., Ltd., functional group degree 2, hydroxyl value 56, number average molecular weight 2000) and 200g of toluene were mixed evenly, maintained at 110°C for 4 hours, and then cooled to room temperature.

[0053] Step 2)

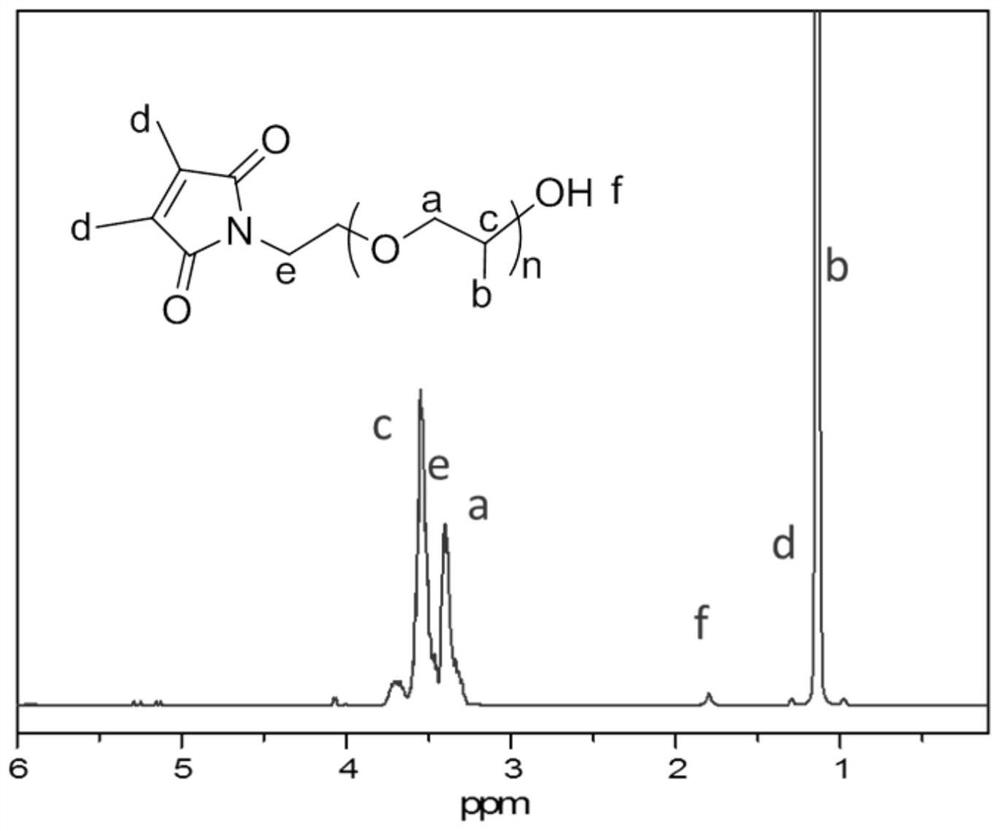

[0054] Add 16.8g of 3,4-dimethylfuran-2,5-dione to the reaction solution in step 1) and raise the temperature to 80°C under stirring, react for 2 hours, and obtain 1# macromonomer containing lactam structure after cooling down solution.

[0055] pass figure 1 It can be seen that the macromonomer prepared in Example 1 has the desired lactam structure.

Embodiment 2

[0057]

[0058] step 1)

[0059] In a reactor with a capacity of 1 liter and equipped with a stirrer, a heater, a thermocouple, a condensing device with a water separator, an inlet device and an outlet device, add under nitrogen protection: 8.9 g of aziridine and 416.4 g (0.2082mol) polyether polyol 2020 (Wanhua Chemical Group Co., Ltd., functional group degree 2, hydroxyl value 56, number average molecular weight 2000) and 200g of toluene, mixed evenly, maintained at 120°C for 4h, and then cooled to room temperature.

[0060] Step 2)

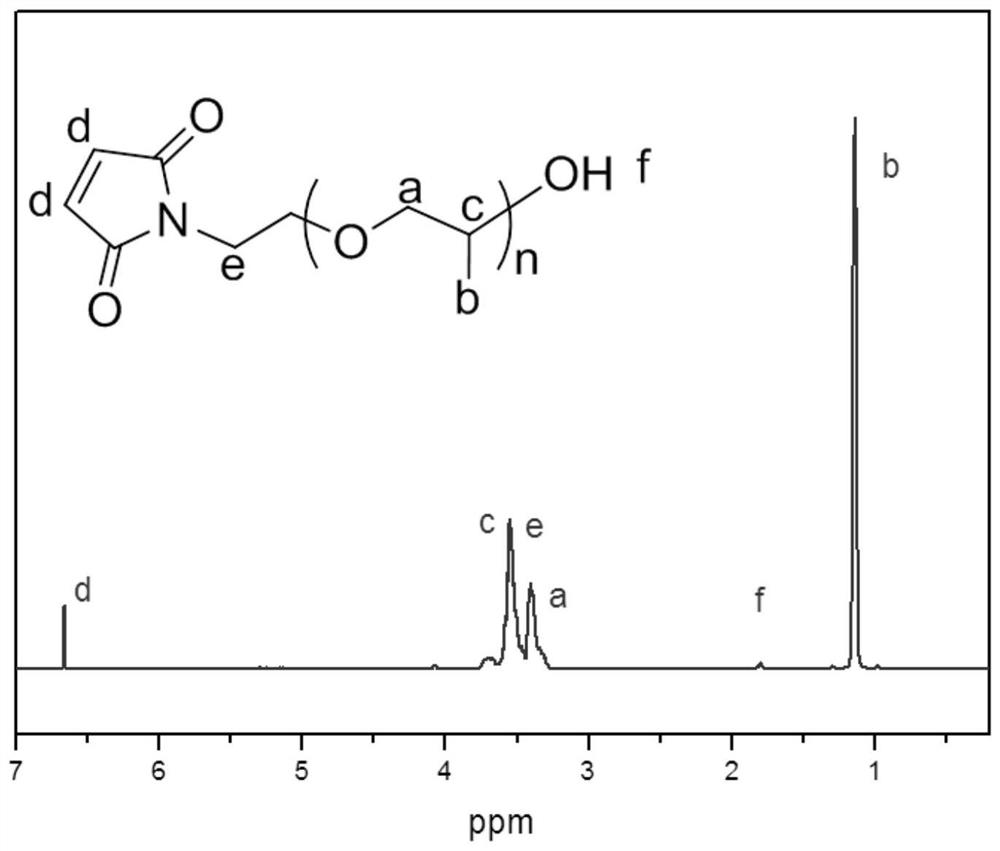

[0061] Add 17.73 g of maleic anhydride to the reaction liquid in step 1) and heat up to 90° C. under stirring, react for 2 hours, and obtain 2# macromonomer solution containing lactam structure after cooling down.

[0062] pass figure 2 It can be seen that the macromonomer prepared in Example 2 has the desired lactam structure.

Embodiment 3

[0064]

[0065] step 1)

[0066] In a reactor with a capacity of 1 liter and equipped with a stirrer, a heater, a thermocouple, a condensing device with a water separator, an inlet device and an outlet device, add under nitrogen protection: 9.4g aziridine and 416.4g ( 0.2082mol) polyether polyol 2020 (Wanhua Chemical Group Co., Ltd., functional group degree 2, hydroxyl value 56, number average molecular weight 2000) and 200g of toluene, after mixing evenly, maintain 130°C for 4h, and then cool to room temperature.

[0067] Step 2)

[0068] Add 18.67g of maleic anhydride to the reaction liquid in step 1) and heat up to 100°C under stirring, react for 2 hours, and obtain 3# macromonomer solution containing lactam structure after cooling down.

[0069] pass figure 2 It can be seen that the macromonomer prepared in Example 3 has the desired lactam structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com