CSP tunnel type roller bottom furnace bottom roller collar and preparation method thereof

A roller hearth furnace and tunnel-type technology, which is applied in the field of CSP tunnel-type roller hearth furnace roll ring and its preparation, can solve problems such as tension damage, skin tearing, meat bite, yield discount, and large consumable parts. Achieve the effect of reducing production cost, reducing replacement cycle and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

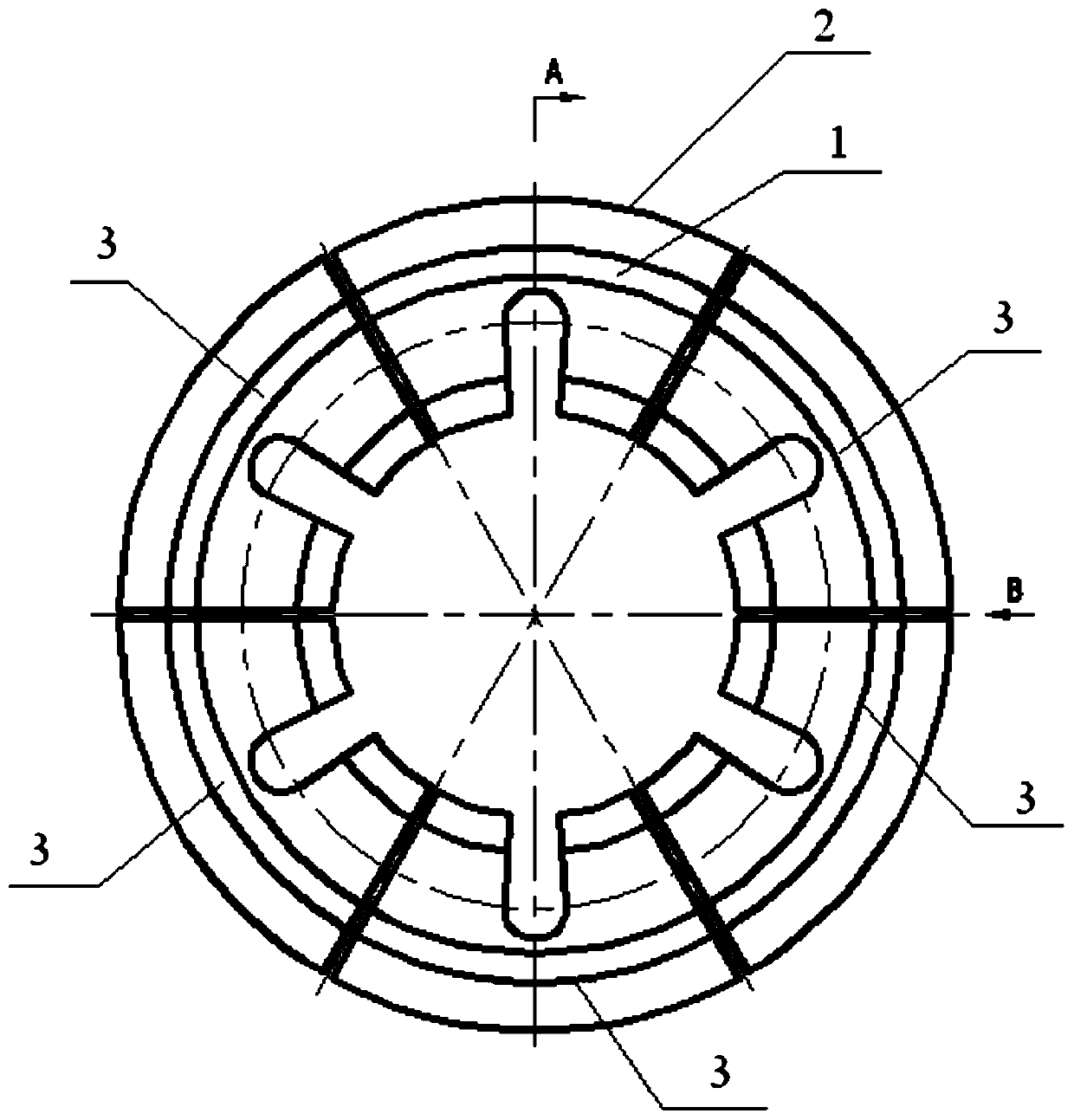

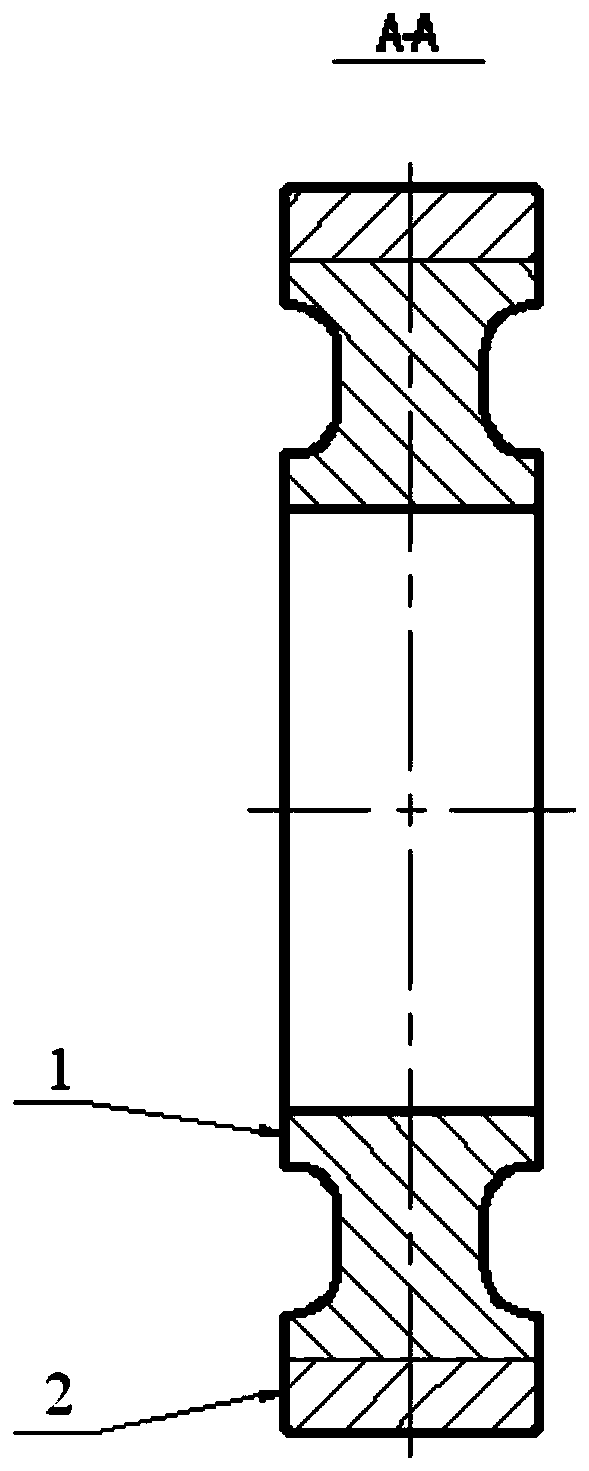

[0029] Such as Figure 1-3 Shown: CSP tunnel-type roller hearth hearth roll ring, including 6 roll ring sheets 3 with the same structure, each roll ring sheet 3 includes an inner ring 1 and an outer ring 2, and the inner ring 1 and the outer ring 2 are at the junction merged with each other without separation.

[0030] The roll rings are sequentially fixed on the hearth roll body in the radial direction.

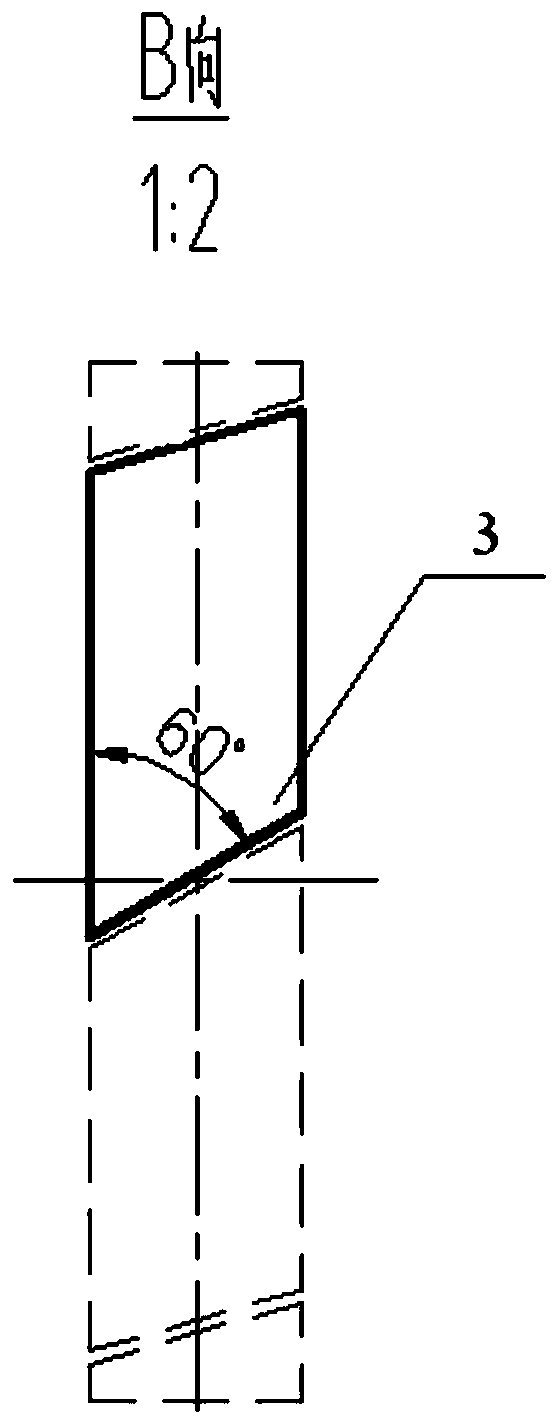

[0031] The gap between each two roll ring sheets 3 is 4 mm, and the gap forms an included angle of 60° with the shaft axis of the hearth roll.

[0032] The material of the inner ring 1 is 06Cr25Ni20, and the material of the outer ring 2 is Co50.

[0033] The effective thickness of the outer ring 2 is 20mm.

[0034] The components of the inner ring 1 are as follows: C≤0.08%; Mn≤2.00%; Si≤1.50%; Cr 24.00%~26.00%; Ni19.00%~22.00%; S≤0.030%; P≤0.035%;

[0035] The outer ring 2 components are as follows: C 0.05%~0.12%; Cr 27%~29%; Co 48%~52%; Mn: 0.5%~1%; impurities P, S≤0.02...

Embodiment 2

[0037] Example 2 Preparation method of roller ring of CSP tunnel type roller hearth furnace

[0038] First of all, molten steel is smelted, and the roll ring is cast by vacuum vertical centrifugal, and then the chemical composition analysis and UT flaw detection of the roll ring are carried out; the roll ring is solid solution; the solid solution treatment is to put the workpiece to be treated in the heat treatment furnace Heating to 1050°C, holding for 2 hours, slowly opening the furnace door gradually within 2 hours, cooling with the furnace, and then air cooling out of the furnace; roughing the crude product obtained from solid solution, and dividing it into 6 roller ring pieces 3 by wire cutting. Then continue to wire-cut each piece of roll ring with an inclined U-shaped groove; assemble the roll ring with the roll body in order and weld it, and finally finish the roll ring according to the drawing, and pack it into the warehouse after the size inspection.

[0039] The ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com