Vector control system, control method and device, air conditioner and storage medium

A technology of vector control and field weakening control, applied in vector control systems, control systems, control of electromechanical brakes, etc., can solve problems such as increasing product costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

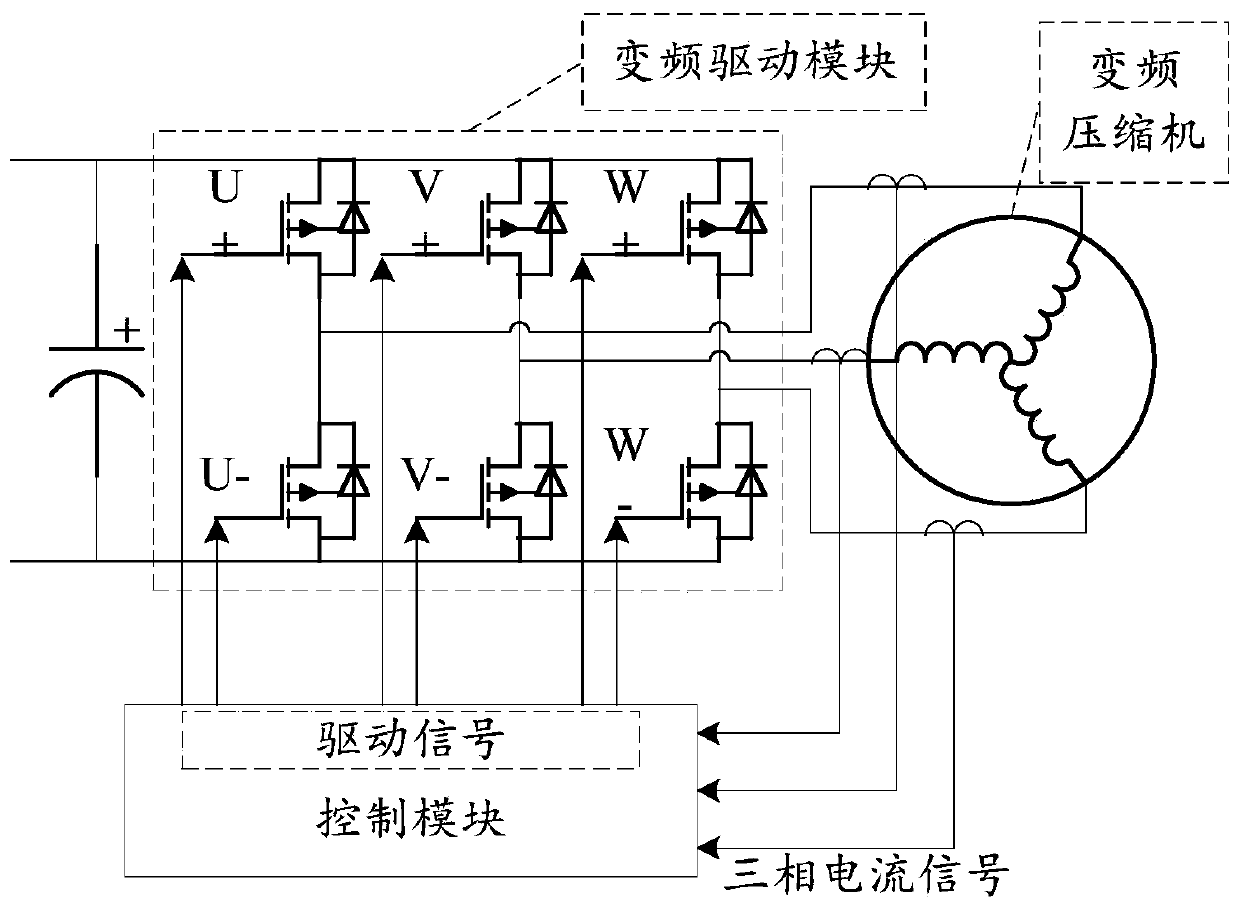

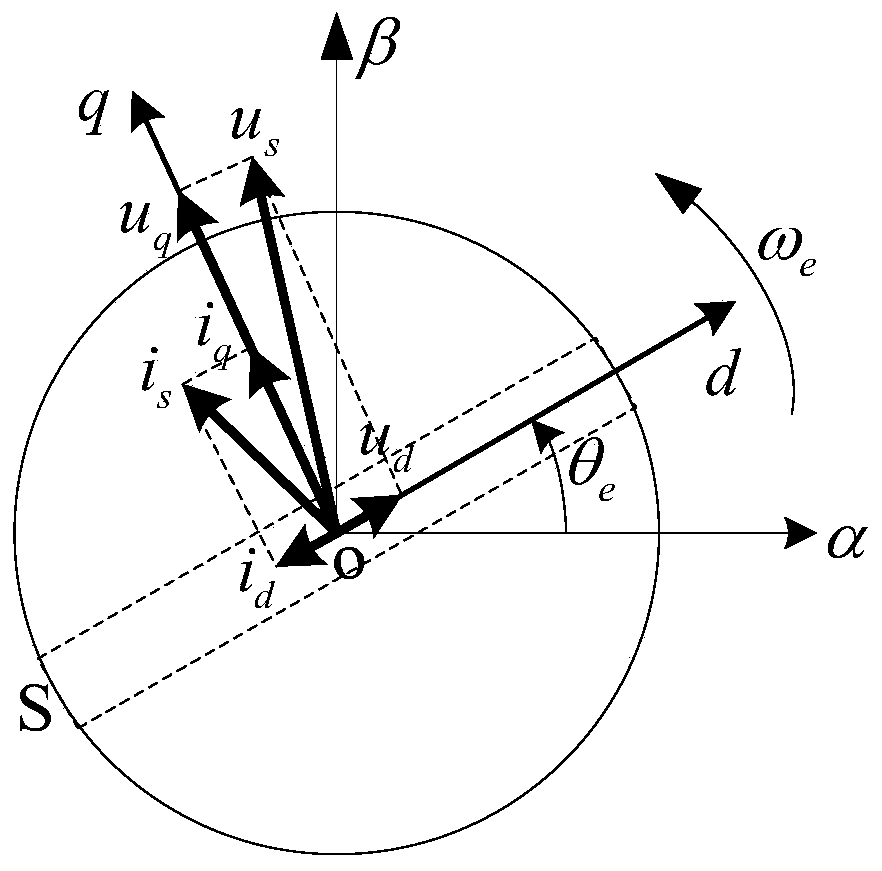

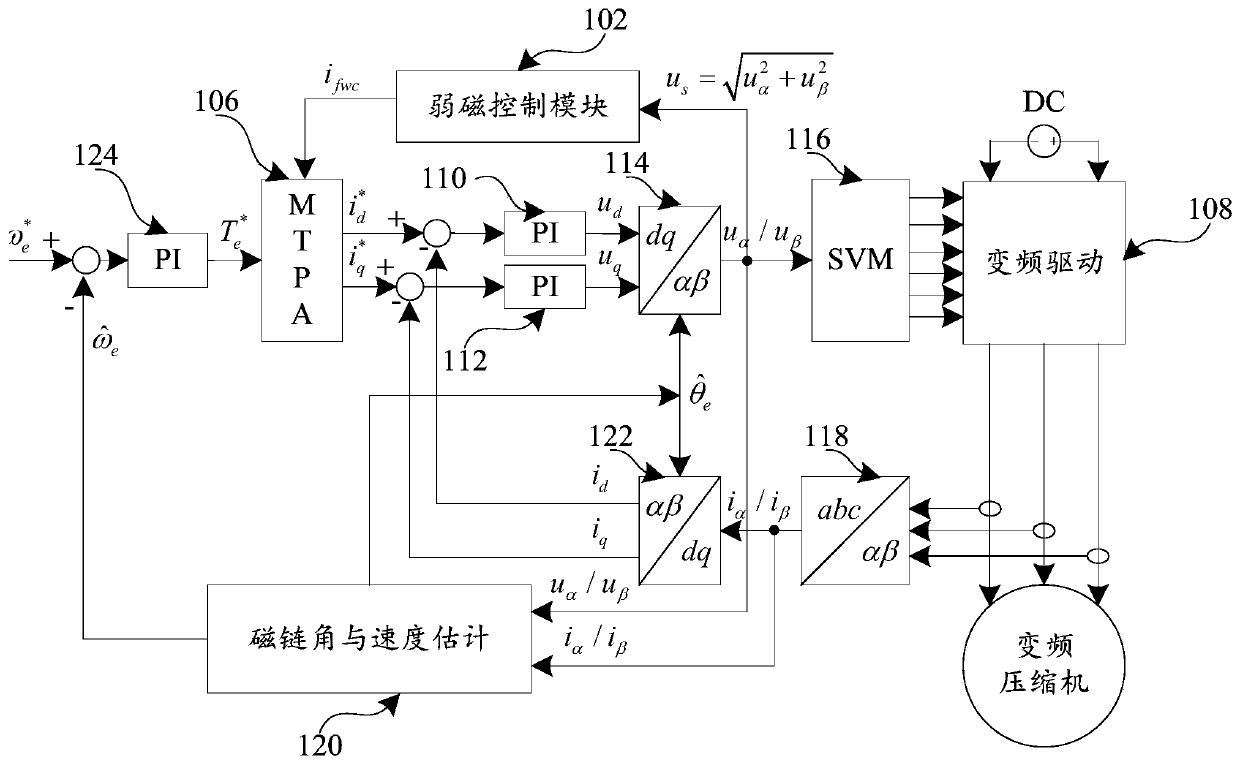

[0055] like figure 1 As shown, the vector control system provided according to the embodiment of the present invention is suitable for variable frequency compressors, including: a control module and a variable frequency drive module 108, wherein, as Figure 5 As shown, the control module includes: a field weakening control unit 102 for outputting a field weakening current; a reactive current control unit 104 for injecting reactive current into the field weakening control unit 102 so that the field weakening control unit 102 modulates the field weakening current according to the reactive current; the maximum torque current ratio control unit 106 receives the input given torque and the modulated field weakening current, and according to the given torque, preset Set the torque current coefficient and the field weakening current to output a given quadrature axis current and a given direct axis current; adjust the module, the adjustment module receives the given quadrature axis cur...

Embodiment 2

[0079] like Image 6 As shown, the operation control method according to the embodiment of the present invention includes: step 602, in the heating mode, inject reactive current into the vector control system, and increase the three-phase current input of the variable frequency compressor by injecting reactive current, so that The permanent magnet synchronous motor in the inverter compressor dissipates heat.

[0080] The operation control method provided by the embodiment of the present invention is applicable to an air conditioner. The air conditioner is equipped with an inverter compressor controlled by a vector control system. During the heating process or / and defrosting process, the temperature of the outdoor environment is detected. Determine whether the permanent magnet synchronous motor needs to generate heat and dissipate heat to reduce the probability of frosting on the outdoor heat exchanger or assist in defrosting. When the outdoor ambient temperature is lower than ...

Embodiment 3

[0090] like Figure 1 to Figure 5 As shown, the embodiment of the present invention provides a low-temperature heating control method based on reactive current of a compressor and a circuit device thereof.

[0091] like figure 1 As shown, the circuit device includes a control chip, a three-phase bridge drive circuit composed of a power switch tube and an inverter compressor. Wherein, the driving circuit may be composed of 6 IGBTs, or 6 MOSFETs, or adopt an intelligent power module IPM, and have anti-parallel diodes at the same time. The control chip outputs a compressor driving signal, and the compressor driving signal controls the operation of the variable frequency compressor through the driving circuit, and detects the phase current of the compressor through the current sensor (three or two or one). The variable frequency compressor is a compressor driven by a permanent magnet synchronous motor.

[0092] In the heating process or / and defrosting process, inject reactive c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com