Surface cerium-rich nanometer cerium-zirconium composite oxide as well as preparation and application thereof

A technology of composite oxides and cerium-zirconium oxides, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of cold start catalysis affecting mobile source catalysis Performance Noble metal utilization efficiency, affecting reduction temperature, oxygen storage performance and high temperature aging performance, poor reduction performance and oxygen storage performance, etc., to achieve excellent oxygen storage performance and reduction performance, good anti-aging performance, and complete grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

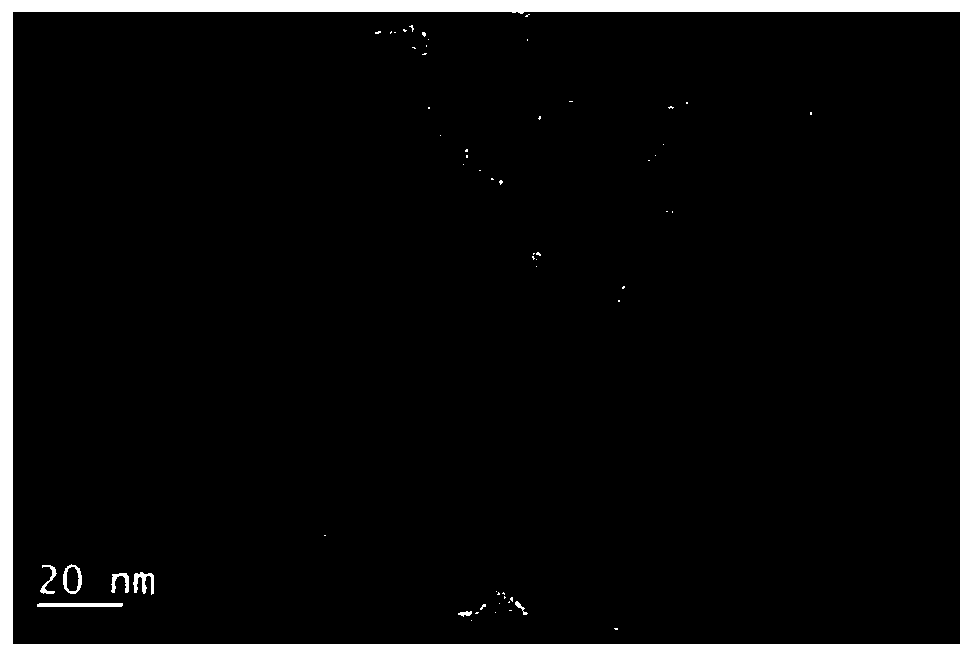

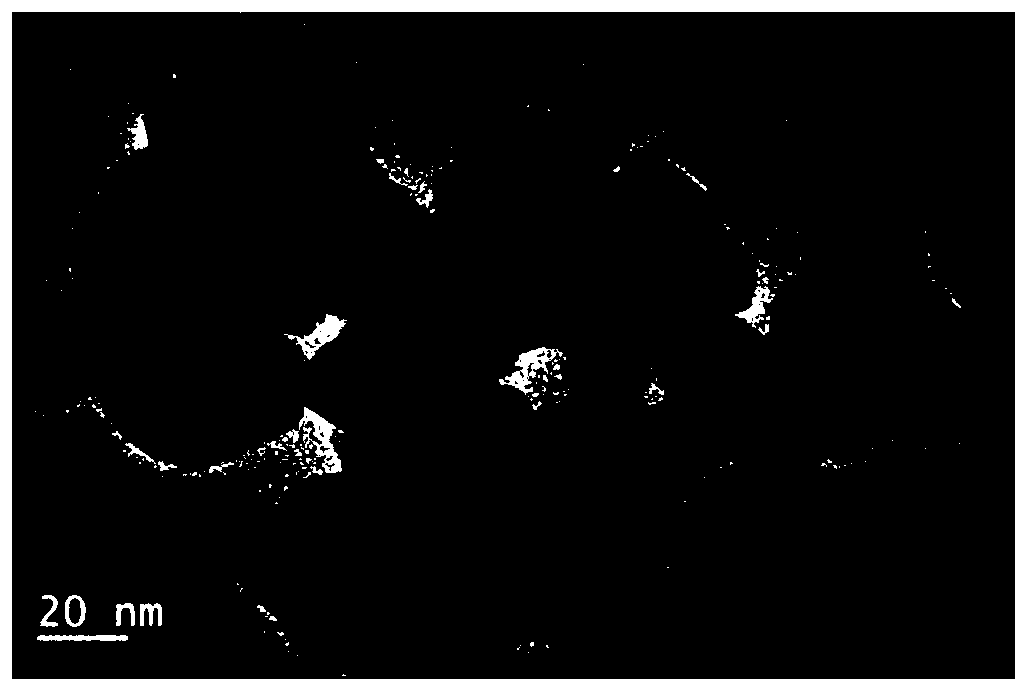

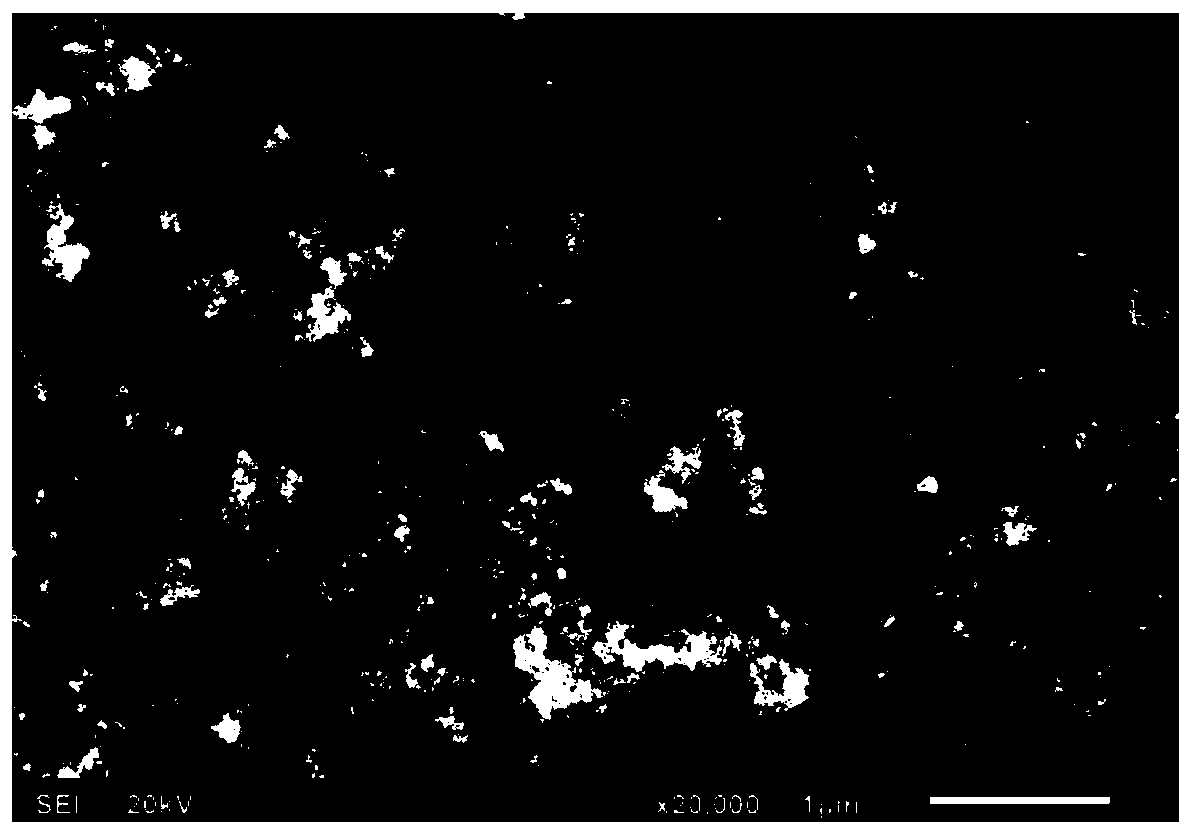

Image

Examples

Embodiment 1

[0042] A composition based on cerium oxide, zirconium oxide, lanthanum oxide, and yttrium oxide is prepared, and the proportions of the composition by weight of oxides are: 52%, 37%, 4%, and 7%. (molar ratio 0.3,0.3,0.0123,0.031)

[0043] 1) In the first beaker, dissolve 182g of cerium ammonium nitrate corresponding to cerium oxide in 500ml of deionized water, add 55g of EDTA, stir for 1h; in the second beaker, add 129.5g of zirconium nitrate corresponding to zirconia, and use 1000mL Dissolve in deionized water and stir for 1 hour; in a third beaker, dissolve 14g of lanthanum nitrate corresponding to lanthanum oxide and 24.5g of yttrium nitrate corresponding to yttrium oxide with 1000mL of deionized water, and stir the solution until clear.

[0044] 2) Mix the solutions in the three beakers, stir until clear, and adjust the pH to 2.0 with ammonia water in a water bath at 40°C. At this time, the solution is clear and no precipitate is formed. The solution was fixed to 7L and i...

Embodiment 2

[0050] Except that the hydrothermal conditions for the first time are different, other conditions are the same as in Example 1. Prepare a composition based on cerium oxide, zirconium oxide, lanthanum oxide, and yttrium oxide. The proportions of the composition by weight of oxides are: 52%, 37%, 4%, and 7%, and the hydrothermal condition of the first step is 220 ℃, 20h. See Table 1.

Embodiment 3

[0052] Except that the hydrothermal conditions for the first time are different, other conditions are the same as in Example 1. The hydrothermal condition of the first step is 180°C for 20h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com