ZSM-12 molecular sieve supported high-dispersion Pt catalyst and preparation method thereof

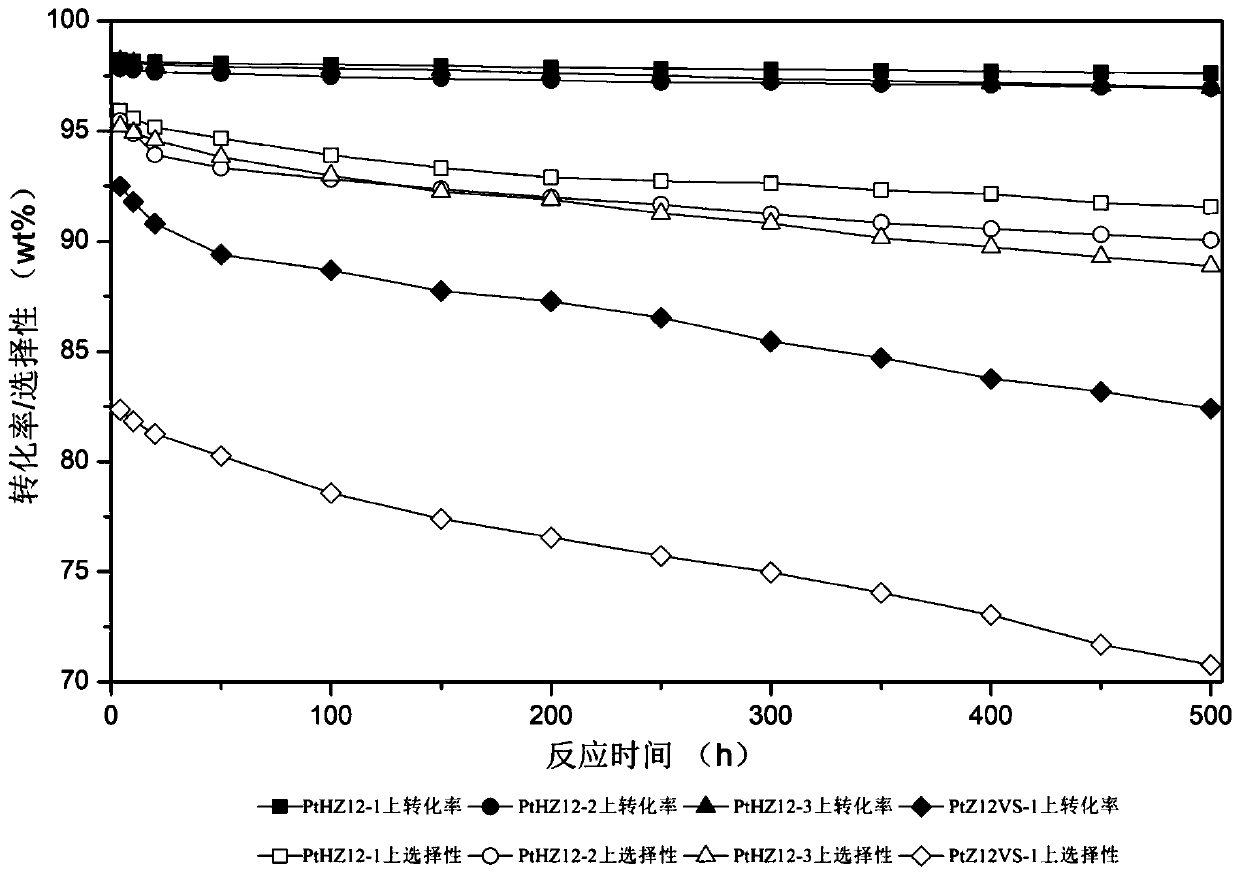

A molecular sieve and catalyst technology, applied in the field of catalytic materials, can solve problems such as poor isomeric selectivity, and achieve the effects of small particle size, easy operation, and excellent anti-coking performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment illustrates the method for preparing Pt-HZSM-12 molecular sieve catalyst:

[0032] 1) Add 0.5g Pt(NH 3 ) 4 ](NO 3 ) 2 , 1.0141g of 3-mercaptopropyltrimethoxysilane, 9.92g of 6.3% NaOH solution were mixed and dissolved, coordinate exchanged, filtered and washed to obtain a water-soluble Pt-S coordination compound;

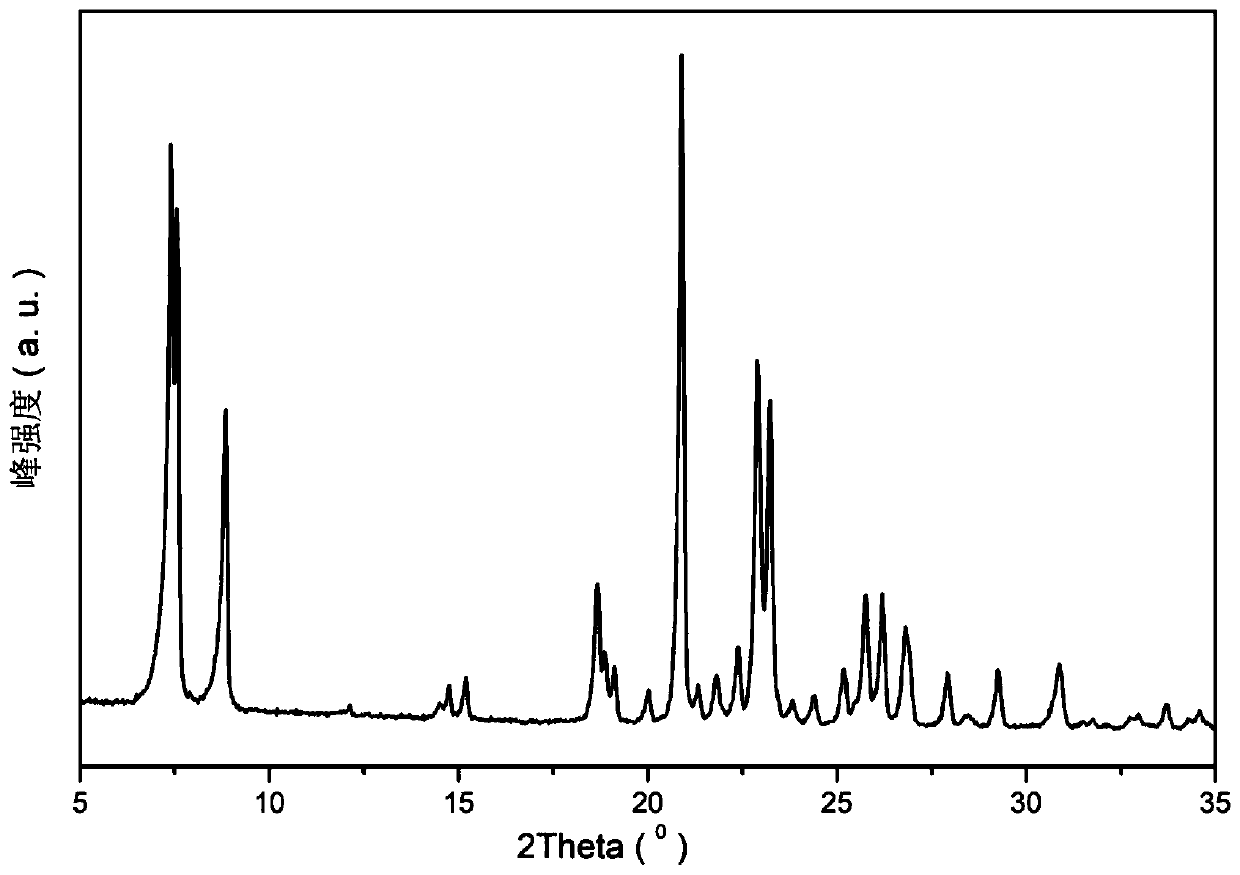

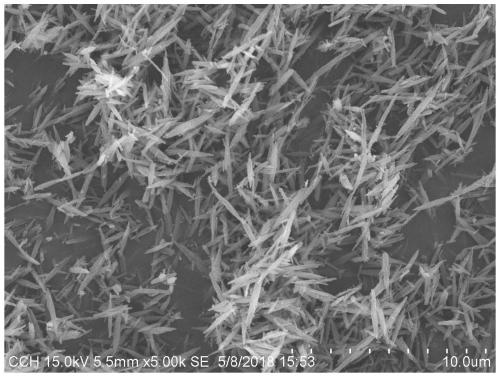

[0033] 2) 100.0g silica sol (SiO 2 Content: 30wt%), 1.3054g pseudo-boehmite (Al 2 o 3 Content: 65wt%), 2.0174g NaOH, 64.8955g concentration of 20% N,N-dimethyl-N'-ethylcyclohexyl ammonium hydroxide (DMECHAOH) and 102.3110g deionized water obtained in 1) A mixed gel formed by a Pt-S coordination compound, in which n(Pt-S):nSiO 2 :nAl 2 o 3 :nNaOH:n(DMECHAOH):nH 2 The molar ratio of O=0.0026:1:0.0167:0.15:0.05:25; then the gel mixture was transferred to a hydrothermal crystallization kettle, and crystallized at 180° C. with a stirring speed of 80 rpm for 72 hours. After the crystallization reaction, the sample was taken out for quench...

Embodiment 2

[0036] This embodiment illustrates the method for preparing Pt-HZSM-12 molecular sieve catalyst:

[0037] 1) 0.75g[Pt(NH2CH2CH2NH2)2]Cl2, 2.3152g 3-mercaptopropyltriethoxysilane, 8.08g concentration of 13.5% NaOH solution are mixed and dissolved, coordinate exchanged, filtered and washed to obtain Water-soluble Pt-S coordination compounds;

[0038] 2) Mix 100.0g ethyl silicate, 1.2255g aluminum isopropoxide, 2.0174g NaOH, 9.5699g N,N-ethyl-N'-dimethylcyclohexylammonium bromide (DMECHABr) and 255.5042g deionized water A mixed gel formed with the Pt-S coordination compound obtained in 1), in which n(Pt-S):nSiO 2 :nAl 2 o 3 :nNaOH:n(DMECHABr):nH 2 The molar ratio of O=0.0041:1:0.0125:0.08:0.08:30; then the gel mixture was transferred to a hydrothermal crystallization tank, and crystallized at 170° C. with a stirring speed of 60 rpm for 96 hours. After the crystallization reaction, the sample was taken out for quenching, filtered, washed, and dried at 105° C. for 12 hours to ...

Embodiment 3

[0041] This embodiment illustrates the method for preparing Pt-HZSM-12 molecular sieve catalyst:

[0042] 1) Add 0.85g [Pt(NH 2 CH 2 CH 2 NH 2 ) 2 ](NO 3 ) 2 , 1.2671g 2-ammonium mercaptoacetate, 11.61g concentration is that 10.0% NaOH solution carries out mixing and dissolving, coordination exchange, obtains the Pt-S coordination compound soluble in water through filtering, washing;

[0043] 2) 100.0g water glass (SiO 2 Content: 25.0wt%, Na 2 O content: 7.5wt%), 1.3054g sodium aluminate (Al 2 o 3 Content: 37.38wt%, Na 2 O content: 29.22wt%), 1.0351g NaOH, 11.6069g benzyltrimethylammonium bromide (BTMABr) and 36.6338g deionized water and the mixed gel formed by the Pt-S coordination compound obtained in 1), the n(Pt-S) in gel: nSiO 2 :nAl 2 o 3 :nNaOH:n(BTMABr):nH 2 The molar ratio of O=0.0047:1:0.0083:0.12:0.18:15; then the gel mixture was transferred to a hydrothermal crystallization tank, and crystallized at 160° C. with a stirring speed of 90 rpm for 144 hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com