2-cun increasing range threading machine

A threading machine and frame technology, which is applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of inability to meet the characteristics of straight thread length, short stroke of the threading machine carriage, labor and time-consuming, etc. The effect of moving work, saving raw materials, and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

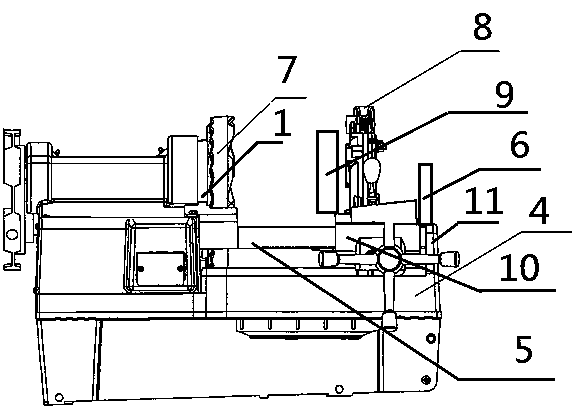

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

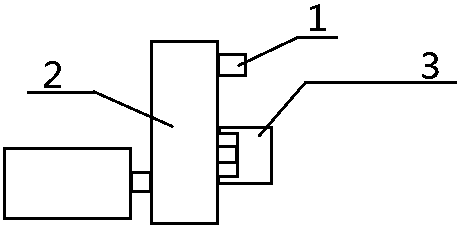

[0017] see figure 1 -2, a kind of 2-inch extended-range pipe cutting and threading machine of the present invention includes an oil pump, a gear box, a frame, a slide rail, and a carriage, and the oil pump is connected with the gear box, and the gear box is installed on the machine. In the frame, the slide rail is fixedly installed on the frame, the center distance of the slide rail is greater than 20 cm and not greater than 27 cm, the slide frame is slidingly set on the slide rail, the stroke of the slide frame is greater than 19 cm, and the maximum is not more than 40 cm , The length of the slide rail matches the stroke of the slide frame, the length of the frame matches the length of the slide rail, the length of the frame matches for fixing the slide rail and expanding the internal space of the frame, and the tool holder is installed on the slide frame.

[0018] F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com