Diamond wire cutting machine

A technology of diamond wire and cutting machine, applied in the direction of working accessories, fine working devices, stone processing equipment, etc., can solve the problems of complex winding mechanism, huge equipment, complicated control, etc., and achieve large cutting range, high working efficiency, Overall compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

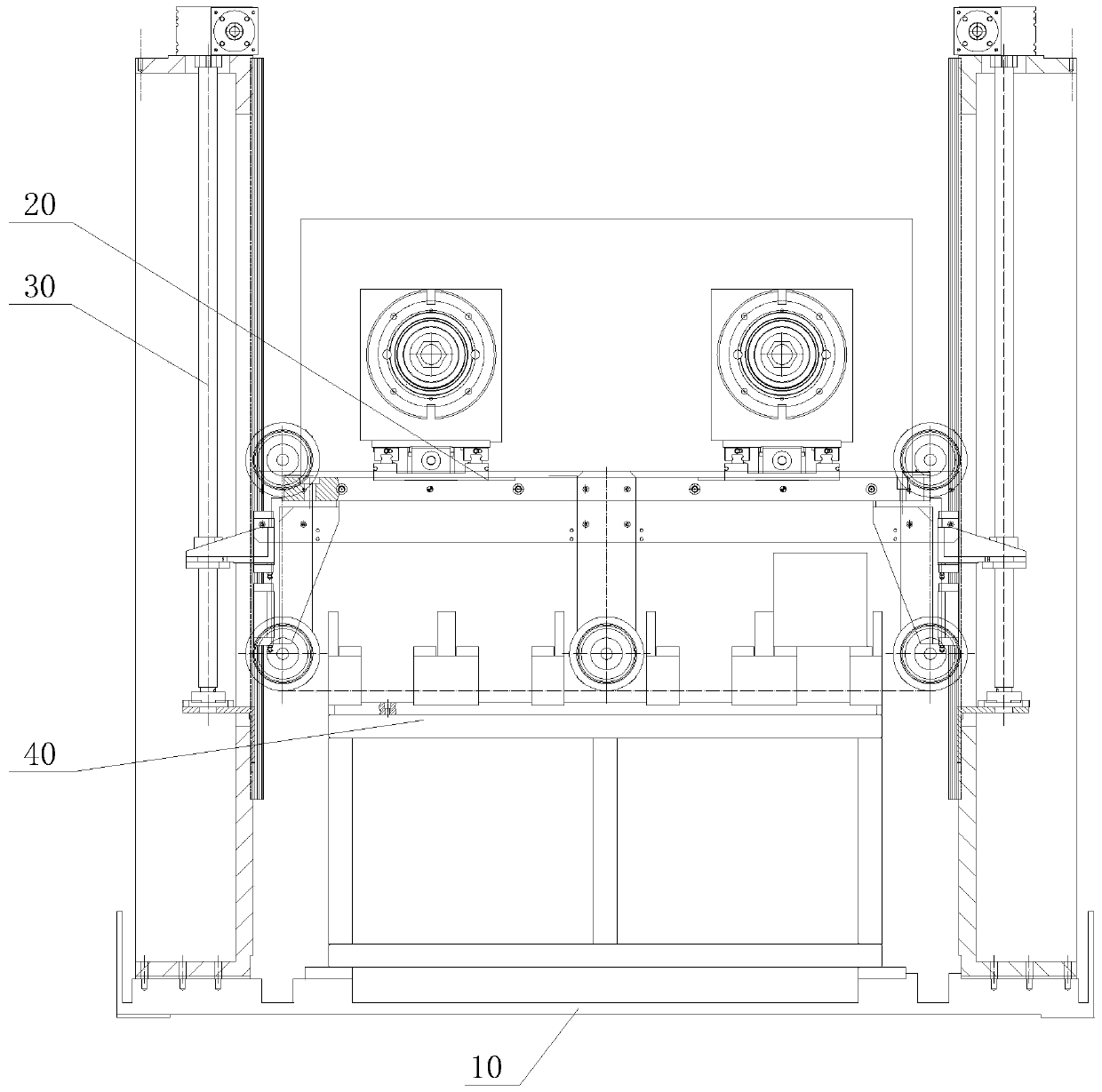

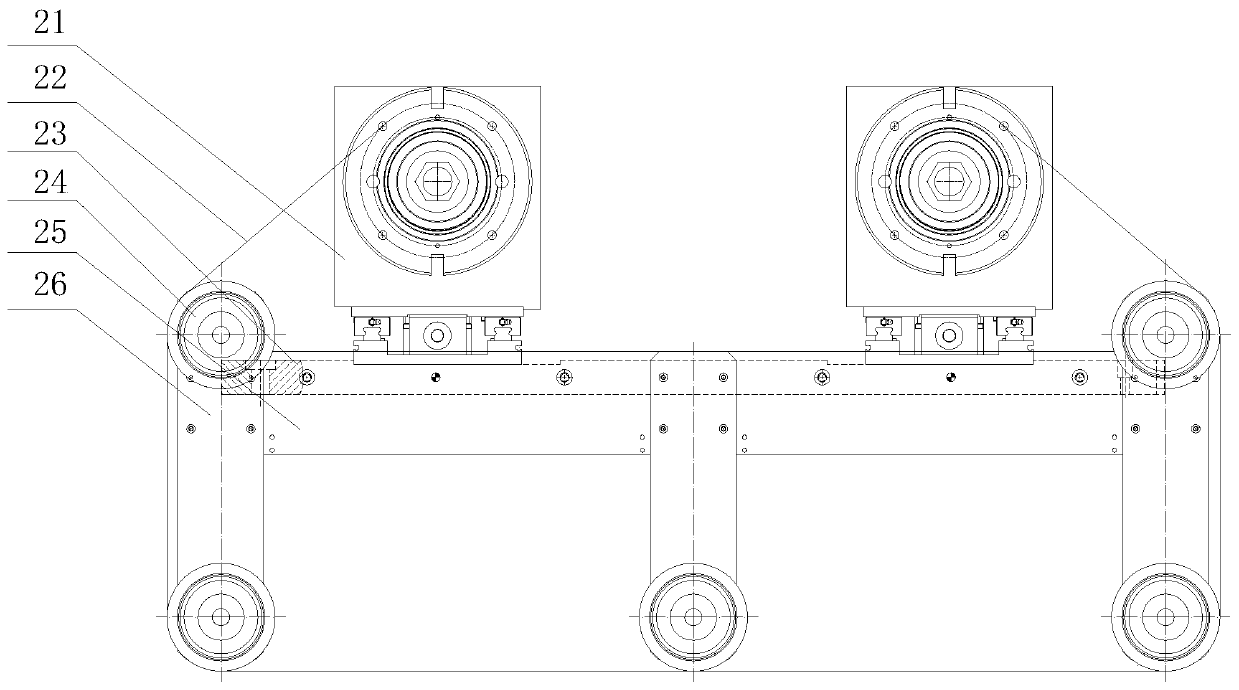

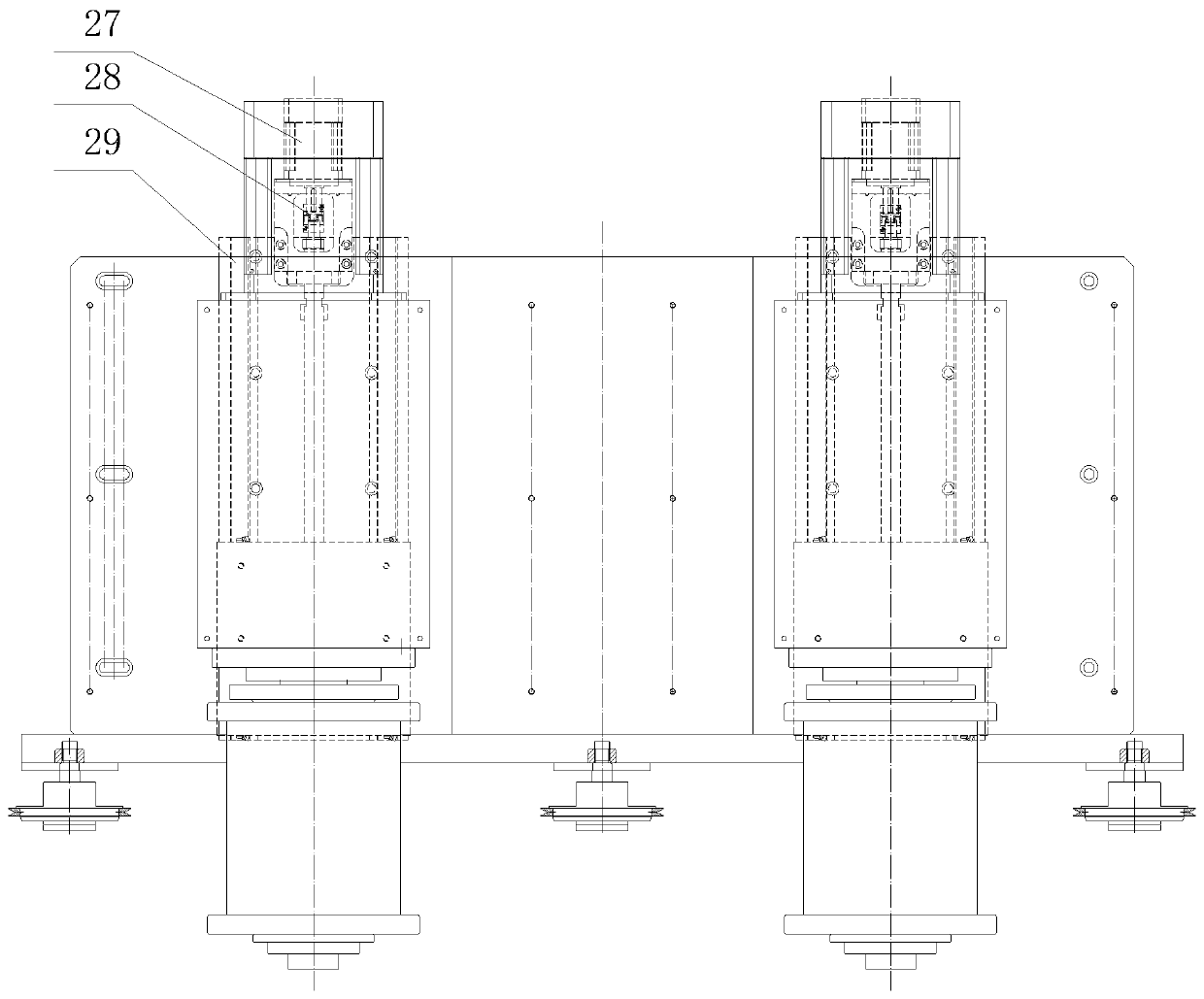

[0030] In order to achieve the purpose of the present invention, as Figure 1 to Figure 7 As shown, a diamond wire cutting machine is provided in one of the embodiments of the present invention, including a base 10, a fixing tool 40 for fixing crystals to be cut, a wire take-up mechanism 20, and a lifting and feeding mechanism 30, which are fixed The tooling 40 is arranged on the base 10, the elevating feed mechanism 30 is installed on the base 10 and is located on the left and right sides of the fixed frock 40, the take-up and release mechanism 20 is installed on the elevating and feed mechanism 30, the take-up and release mechanism 20 includes a retractable Line workbench 23, two modules 29, two take-up and pay-off assembly 21, diamond wire 22, at least two take-up and take-off guide wheels 24 and two translation motors 27, the two ends of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com