Hydrophobic plastic film and preparation method thereof

A plastic film, hydrophobic technology, applied in the field of hydrophobic plastic film and its preparation, can solve the problems of human health threat, easy shedding, poor coating durability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

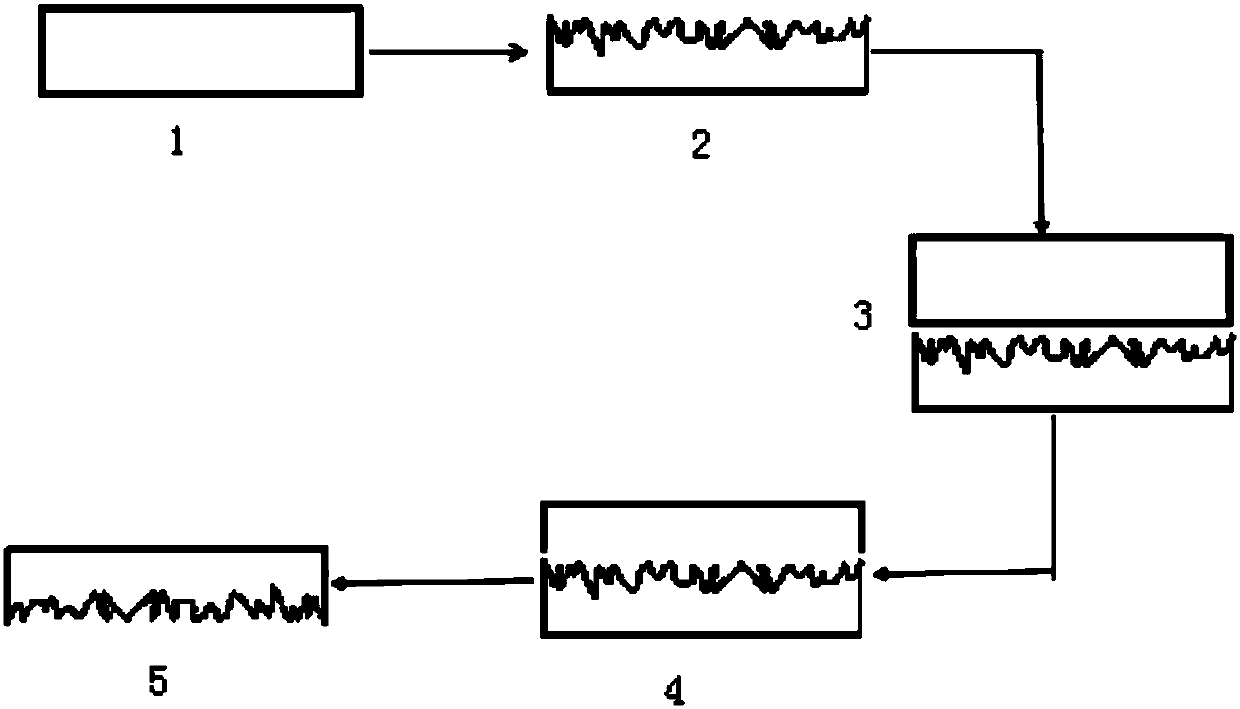

Image

Examples

Embodiment 1

[0022] First, the aluminum sheet is polished, and then the polished aluminum sheet is ultrasonically cleaned with ethanol, and dried at room temperature.

[0023] Use a sandblasting machine to treat the surface of the cleaned aluminum sheet for 3 minutes. Laminate a PP plastic plate with a thickness of 1mm on top of the sandblasted aluminum sheet and put it on the embossing machine for embossing. The printing temperature is 200°C, the pressure is 12kPa, and the printing is carried out for 10 minutes. After that, the PP plastic plate after the printing treatment is demolded to obtain a PP plastic film, and the contact angle of the surface of the PP plastic film is tested.

Embodiment 2

[0025] First, the aluminum sheet is polished, and then the polished aluminum sheet is ultrasonically cleaned with ethanol, and dried at room temperature.

[0026] The surface of the aluminum sheet is treated with a sandblasting machine, and the processing time is 3 minutes. A PE plastic plate with a thickness of 1mm is laminated on the top of the sandblasted aluminum sheet, and placed on the embossing machine for embossing treatment. The embossing temperature is After embossing for 10 minutes at 150°C and a pressure of 12kPa, the embossed PE plastic plate was demolded to obtain a PE plastic film, and the contact angle on the surface of the PE plastic film was tested.

Embodiment 3

[0028] First, the aluminum sheet is polished, and then the polished aluminum sheet is ultrasonically cleaned with ethanol, and dried at room temperature.

[0029] Use a sandblasting machine to process the surface of the cleaned aluminum sheet for 3 minutes. A PET plastic plate with a thickness of 0.1mm is laminated on top of the sandblasted aluminum sheet and placed on the imprinting machine for embossing. The embossing temperature was 200°C, the pressure was 10kPa, and after 10 minutes of embossing, the embossed PET plastic plate was demolded to obtain a PET plastic film, and the contact angle of the PET plastic film surface was tested.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com