Double-faced adhesive tape automatic laminating machine for CAP-series injection moulded part

A technology for double-sided tape and injection molded parts, which is applied in the field of CAP series injection molding double-sided tape automatic laminating machine, which can solve the problems of increasing labor costs and achieve the effects of labor saving, high precision and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, a clear and complete description will be made below in conjunction with the technical solutions in the embodiments of the present invention. Obviously, the described embodiments are part of the embodiments of the present invention, and Not all examples. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

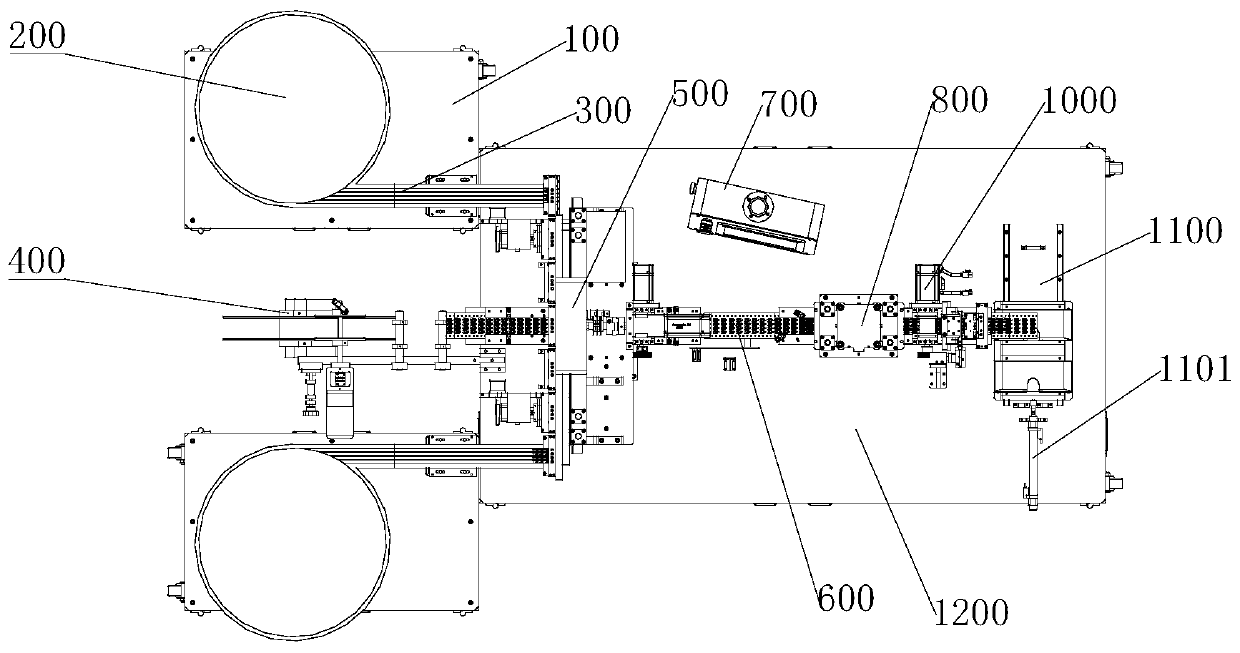

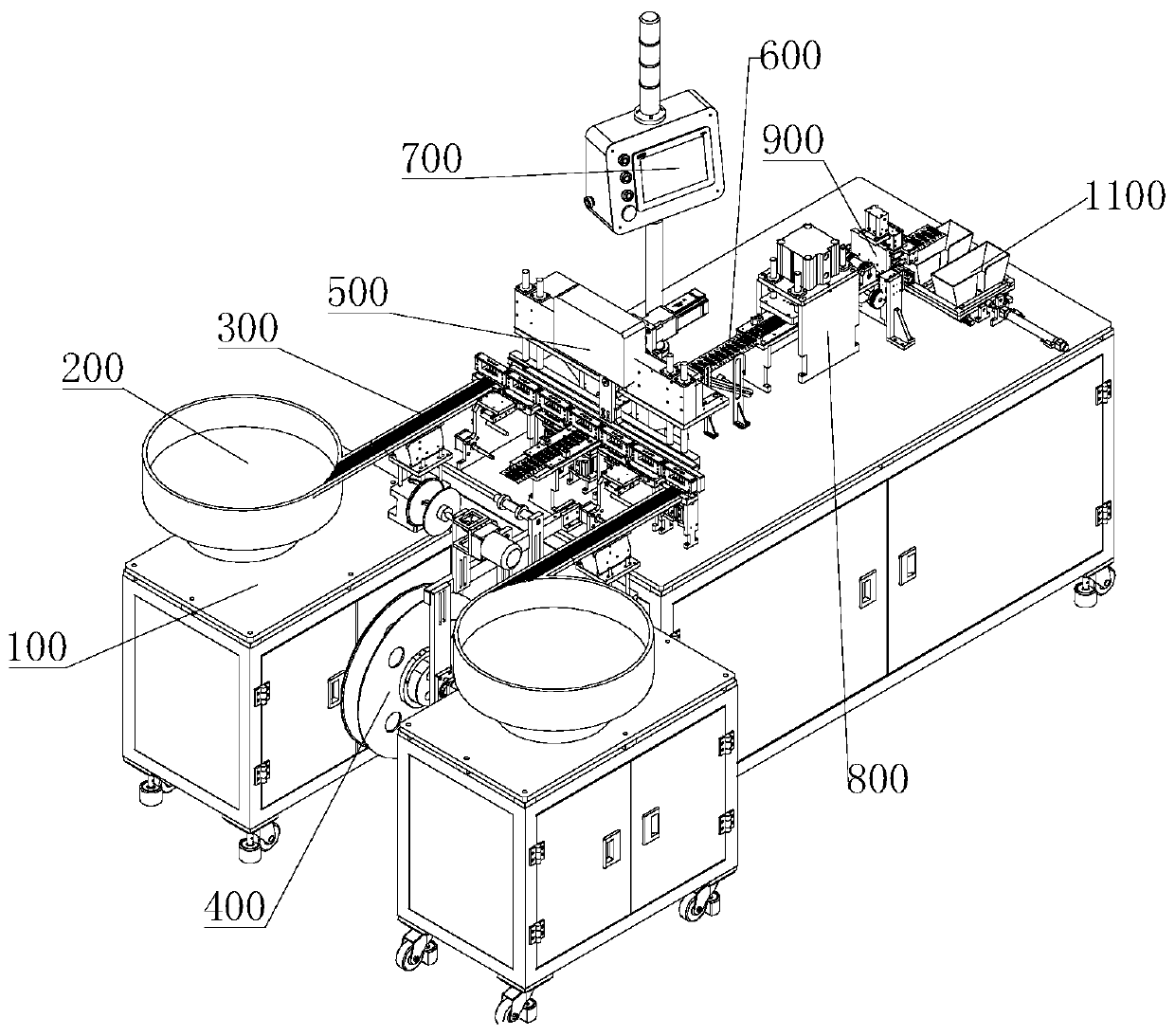

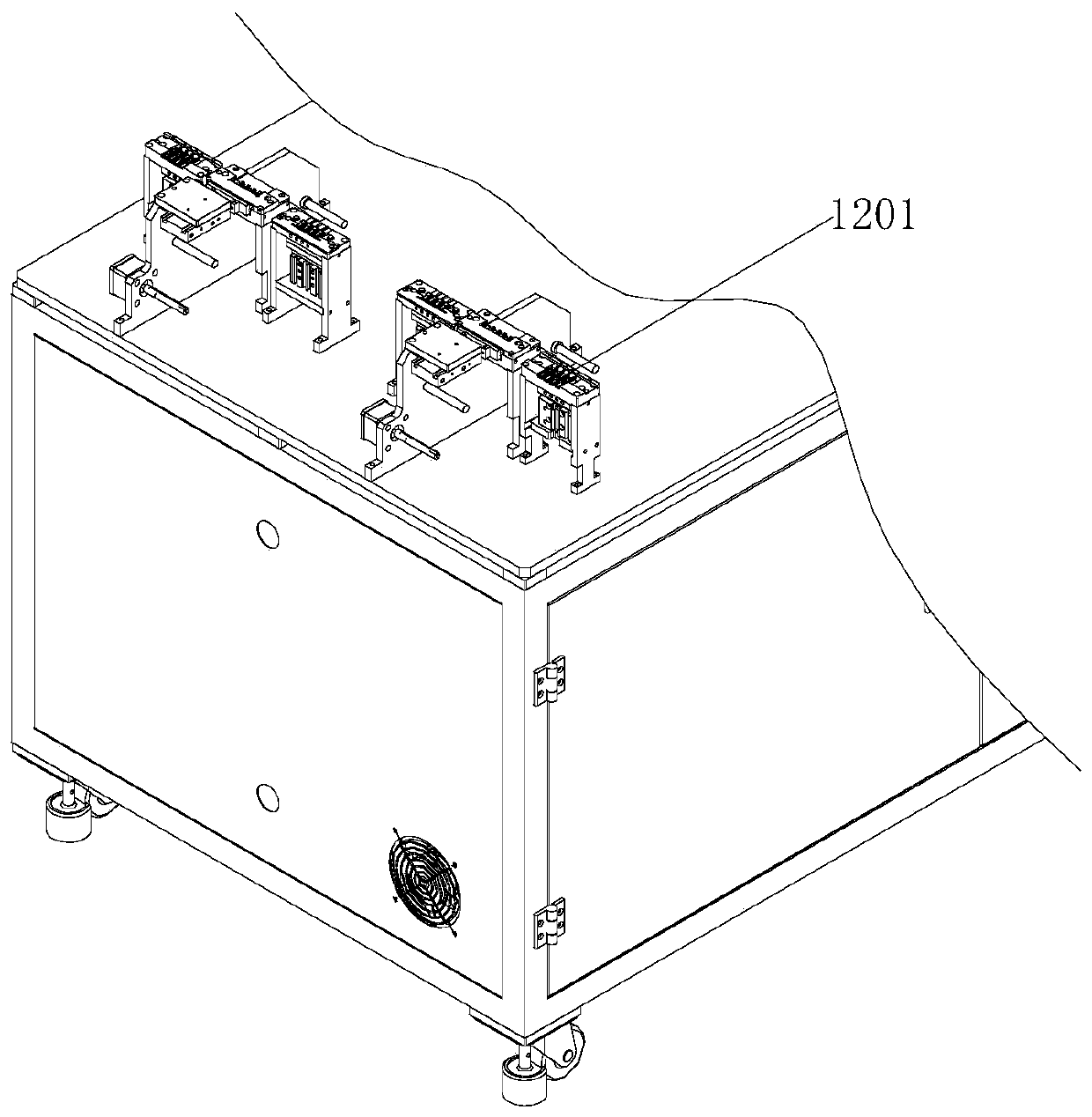

[0028] Such as Figure 1-Figure 9As shown, a CAP series injection molding double-sided adhesive automatic laminating machine includes a front-end body 100 and a rear-end body 1200, and a frame group 1201, a double-sided adhesive material box 400, and a material distribution mechanism 500 are installed on the rear-end body 1200 , DC channel 600, human-computer interaction box 700, pressing mechan...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap