Refinery gas hydrogenation combination process

A combined process and refinery technology, applied in hydrotreating process, petroleum industry, treatment of hydrocarbon oil, etc., to achieve the effect of solving temperature rise, reducing operating energy consumption, and reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The process and effect of the combined hydrogenation method of the present invention will be further described below in conjunction with the examples, but the following examples do not constitute a limitation to the method of the present invention.

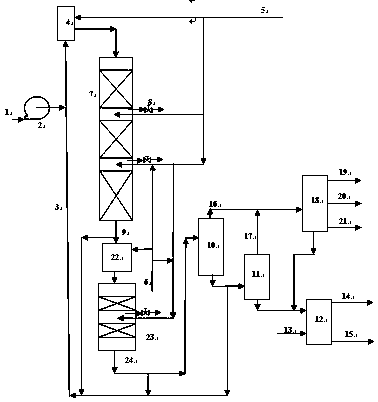

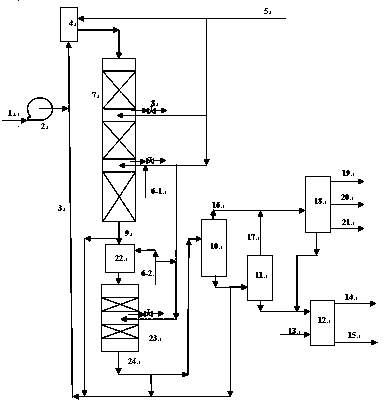

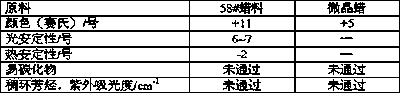

[0034] A hydrogenation combination method of the present invention is specifically implemented as follows: raw material oil 1 is mixed with circulating oil 3, and the mixed material and hydrogen gas are mixed in the hydrogen dissolver 4 and then enter the hydrogenation reactor 7, and pass through the first catalyst bed , hydrogen is dissolved in the effluent of the first catalyst bed, and passes through the second catalyst bed, hydrogen and gaseous material 6 are dissolved in the effluent of the second catalyst bed, and passes through the third catalyst bed, the third catalyst bed The reaction effluent 9 is mixed with the gaseous material 6 in the gas dissolver 22 and enters the supplementary reactor 23, and passes through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com